English

English

Optimizing Energy Efficiency in Sustainable Field Distillation Practices for Enhanced Resource Utilization

Field Distillation Unit A Comprehensive Overview

Field distillation units (FDUs) are specialized equipment designed for the on-site distillation of various materials, primarily in the oil and gas industry, as well as in the production of biofuels and chemical products. These units play a crucial role in enhancing the efficiency of resource extraction and refining processes, allowing for immediate processing closer to the source, thus reducing transportation costs and associated carbon footprints.

The fundamental principle behind field distillation is the separation of different components from a mixture based on their boiling points. In a typical FDU, crude oil or other raw materials are fed into the system, where they undergo heating to vaporize the lighter fractions. As the temperature increases, these vapors rise through a series of trays or packing materials, where cooling mechanisms facilitate the condensation of heavier fractions, allowing for their collection and further processing. This multi-stage process enables the extraction of various hydrocarbons, including naphtha, kerosene, diesel, and residual oils.

One of the primary advantages of FDUs is their mobility. Traditional distillation processes are typically established in fixed refinery locations, which require extensive infrastructure and can lead to significant operational costs. In contrast, mobile field distillation units can be transported directly to remote drilling sites, enabling real-time processing of extracted resources. This capability is particularly valuable in offshore operations, where logistical challenges can hinder timely resource utilization. Moreover, FDUs can also be adapted to meet specific site conditions, enhancing their versatility and operational efficiency.

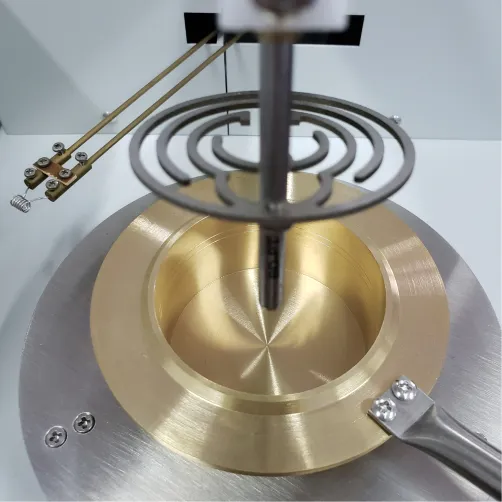

field distillation unit

Environmental considerations are becoming increasingly important in industrial practices. Field distillation units can significantly reduce the environmental impact associated with transportation and processing of raw materials. By processing resources on-site, companies can minimize emissions related to transportation and reduce the risk of spills and leaks that can occur during the transfer of materials. Furthermore, FDUs can be designed to incorporate advanced technologies that enhance energy efficiency and reduce waste. For instance, heat recovery systems can capture and reuse heat generated during distillation, minimizing energy consumption and operational costs.

In addition to the oil and gas sector, field distillation technology is gaining traction in the renewable energy realm, particularly in the production of biofuels. The demand for sustainable energy sources has led to innovations in converting biomass into liquid fuels through distillation processes. FDUs can be employed to process bio-oils derived from plant material, facilitating the conversion of agricultural waste into useful energy products. This not only contributes to energy independence but also promotes sustainable practices by utilizing resources that would otherwise go to waste.

Challenges associated with field distillation units primarily revolve around operational efficiency, maintenance, and safety considerations. As these units operate under high temperatures and pressures, ensuring the integrity of the equipment is paramount. Regular maintenance, operator training, and adherence to safety protocols are essential to mitigate risks associated with operating FDUs offshore or in remote locations.

In conclusion, field distillation units represent an innovative solution to meet the evolving needs of the oil, gas, and renewable energy industries. Their mobility, efficiency, and environmental benefits position them as an essential component of modern resource extraction and processing. As technology continues to advance, the capabilities and applications of FDUs are likely to expand, further enhancing their role in promoting sustainable and efficient energy practices worldwide.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024