English

English

pensky martens closed tester

Understanding the Pensky-Martens Closed Tester A Key Tool in Fuel Testing

The Pensky-Martens Closed Tester is a crucial instrument in the field of fuel testing, specifically designed to measure the flash point of liquids. This measure is vital for assessing the safety and suitability of various fuels used in industries such as aviation, automotive, and manufacturing. Understanding the functionality and application of the Pensky-Martens tester provides essential insights into its significance in ensuring fuel quality and safety.

What is Flash Point?

Flash point refers to the lowest temperature at which a liquid can form an ignitable mixture in air. Determining the flash point is critical because it indicates the volatility of the liquid and its potential fire hazards. Fuels with low flash points pose higher risks of accidental ignition, making precise measurement a priority in industrial applications.

Design and Functionality

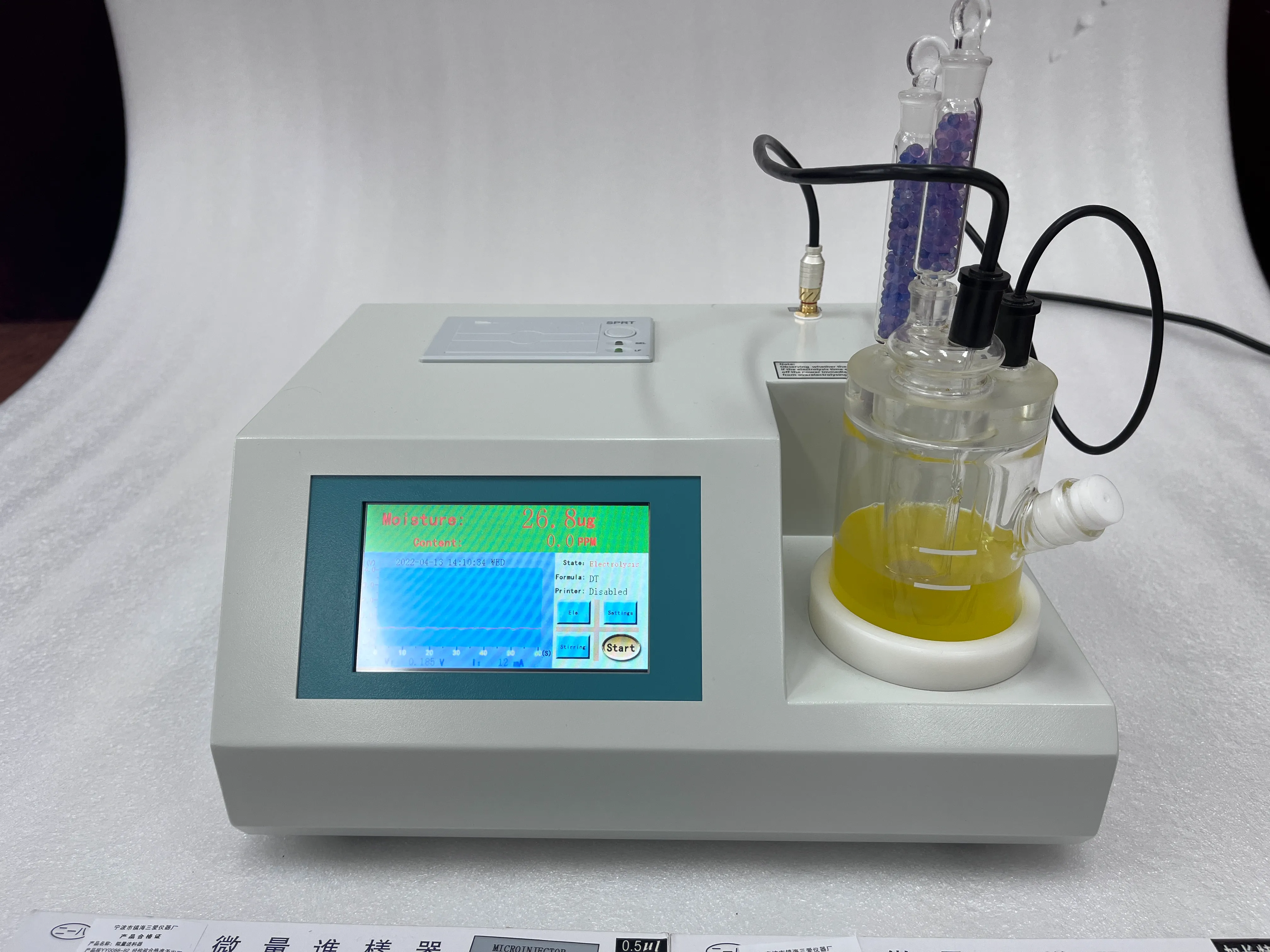

The Pensky-Martens Closed Tester operates under controlled conditions to provide accurate flash point readings. It consists of a closed cup, a heating element, a stirrer, and an ignition source. During the testing process, the sample is placed in the cup and gradually heated. A moving lid ensures that the atmosphere remains controlled, reducing the risk of external influences on the results.

pensky martens closed tester

The test begins with the sample being stirred to maintain uniform temperature distribution. As the temperature rises, the tester carefully monitors the vapor produced by the fuel. An ignition source is introduced at predetermined intervals to detect the flash point. When the vapor ignites, it signals that the flash point has been reached, allowing for precise temperature recording.

Importance in Industry

The Pensky-Martens Closed Tester is particularly valuable across various sectors. In the petroleum industry, for instance, it helps determine the safety characteristics of fuels before they are distributed and used. Aviation fuels must adhere to stringent safety standards to prevent in-flight fires or explosions; hence accurate flash point measurements are essential.

Furthermore, regulatory bodies often require compliance with specific flash point standards to ensure public safety. Industries that produce solvents, paints, and coatings also utilize the Pensky-Martens tester to evaluate the fire hazards associated with their products. By establishing a clear understanding of a substance's flash point, manufacturers can implement proper storage, handling, and transportation guidelines.

Conclusion

In conclusion, the Pensky-Martens Closed Tester is a fundamental tool in fuel testing that significantly contributes to safety across multiple industries. By accurately measuring the flash point of various liquids, it plays a crucial role in preventing accidents and ensuring compliance with safety regulations. As industries continue to evolve and expand, the importance of reliable testing methods like the Pensky-Martens cannot be overstated. Ensuring both fuel quality and safety ultimately safeguards people and the environment, a responsibility that organizations must diligently prioritize.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024