English

English

portable oil analysis equipment price

Portable Oil Analysis Equipment Pricing Insights

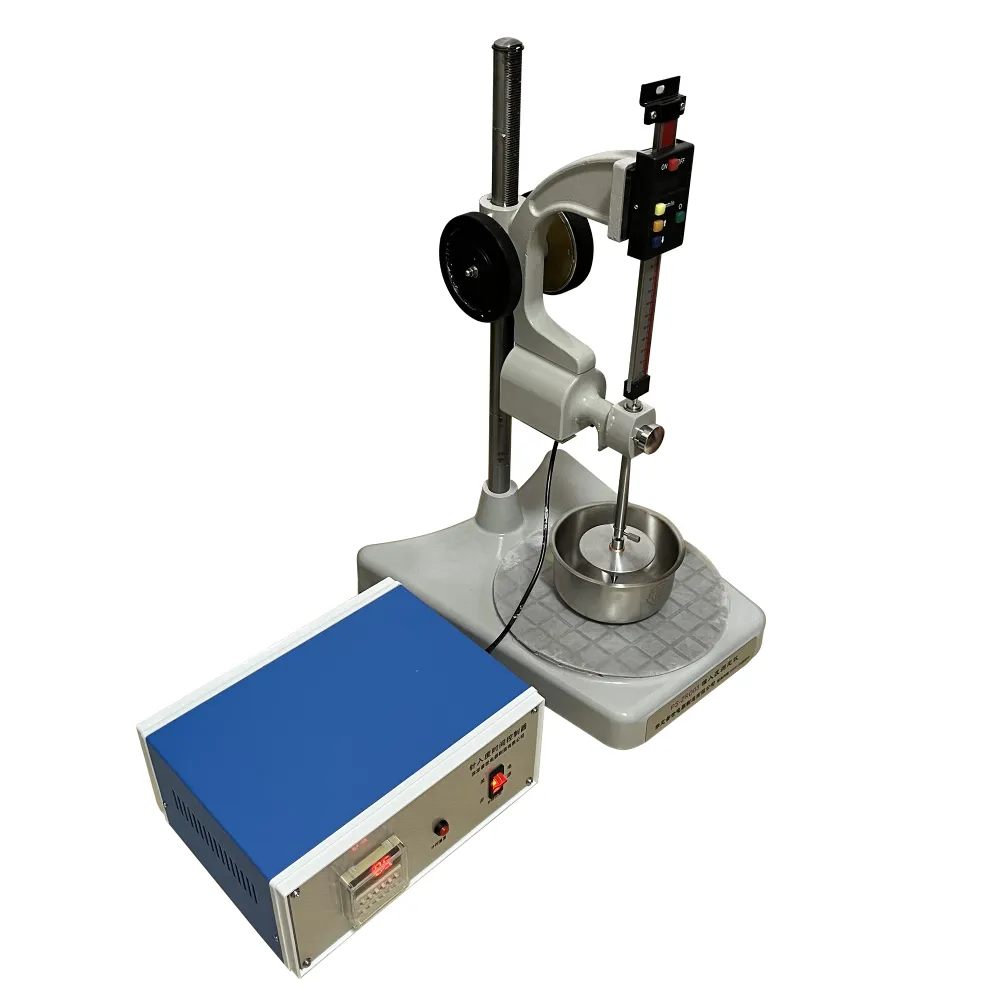

In the industrial and manufacturing sectors, the quality of oil used in machinery is crucial for efficient operation and longevity of equipment. As such, the demand for portable oil analysis equipment has surged. This equipment allows technicians to conduct on-site tests to assess the condition of lubricants, hydraulic fluids, and fuels. The convenience of portable analysis not only reduces downtime but also enhances maintenance strategies, providing businesses with a proactive approach to equipment care.

The price of portable oil analysis equipment can vary widely depending on several factors, including brand, features, and the specific types of tests that the equipment can perform. Basic models that focus on key parameters such as viscosity and moisture content may be available for as low as $500. These entry-level devices are ideal for smaller operations that require straightforward testing without the need for advanced diagnostics.

On the other end of the spectrum, more sophisticated portable oil analysis systems can range from $2,500 to over $10,000. These high-end models often come equipped with advanced features such as spectrometric analysis, particle counting, and the ability to test multiple oil types simultaneously. Additionally, these systems often provide real-time data, which is invaluable for monitoring oil condition in critical applications.

portable oil analysis equipment price

When considering an investment in portable oil analysis equipment, it is essential to weigh not only the upfront cost but also the long-term benefits. Regular oil testing can lead to significant cost savings by identifying potential issues before they escalate into costly repairs or equipment failures. Furthermore, improved oil maintenance practices can extend the life of machinery, resulting in less frequent replacements and a reduction in overall operating costs.

Purchasing decisions should also take into account the availability of support and training from the manufacturer. Some companies offer comprehensive training programs to ensure that technicians can effectively use the equipment and interpret the results. This added value can make a notable difference in how effectively the equipment is deployed within an organization.

In conclusion, while the price of portable oil analysis equipment varies significantly, the investment can yield considerable returns in the form of enhanced equipment reliability, prolonged oil life, and optimized maintenance schedules. Businesses must assess their specific needs, consider the potential return on investment, and choose equipment that aligns with their operational goals to make the most of this essential tool in modern maintenance practices.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024