English

English

power transformer testing and commissioning

Power Transformer Testing and Commissioning

Power transformers are critical components in electrical power systems, facilitating the transmission and distribution of electricity from generation sources to consumers. Ensuring their reliability and efficiency is paramount, which is why rigorous testing and commissioning processes are essential to ascertain their operational integrity and performance.

Importance of Testing

The testing of power transformers is vital for several reasons. First, it helps identify manufacturing defects and design flaws that could lead to failures during operation. Second, it ensures compliance with industry standards and specifications, which are crucial for the safe operation of the electrical grid. By identifying potential issues before they escalate, utilities can save significant maintenance costs and prevent outages.

Types of Tests

Testing of power transformers usually falls into two main categories factory tests and field tests

.1. Factory Tests Before a transformer leaves the manufacturing facility, various tests are performed to check its functionality and safety. These may include

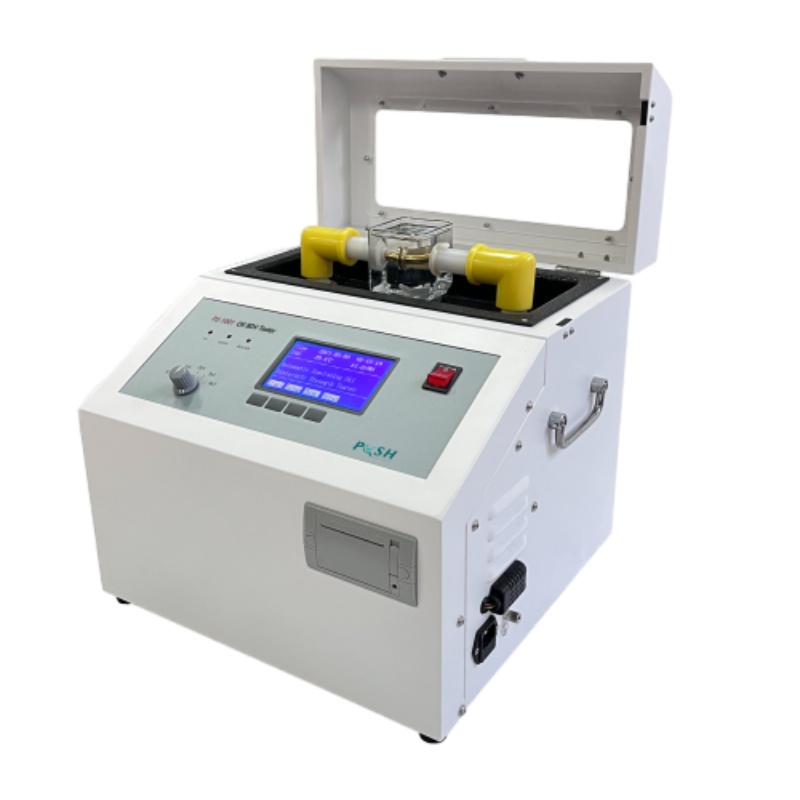

- Winding Resistance Test This test checks the resistance of the transformer windings to ensure they are within acceptable limits. - Insulation Resistance Test Insulation resistance can indicate potential problems, such as moisture ingress or material degradation. - Power Factor Test This evaluates the insulation system's performance and helps identify any weaknesses in the insulation material.

power transformer testing and commissioning

2. Field Tests After installation, the transformer undergoes several tests to confirm its readiness for operation. These tests include

- Transformer Turns Ratio (TTR) Test This measures the turns ratio of the transformer windings, ensuring they match the design specifications. - Swept Frequency Response Analysis (SFRA) This test detects mechanical deformations and changes in the transformer core or windings that might occur during transport and installation. - Bushing Condition Assessment Since bushings are critical components of transformers, regular inspections and tests help ensure their performance is not compromised.

Commissioning Process

The commissioning of power transformers is the final step in the testing phase, where all systems are checked comprehensively. This process typically involves

- Verification of Installation Ensuring all electrical connections and mechanical installations are performed according to the design documentation. - Functional Tests Tests to ensure that the transformer operates correctly under load conditions. - Protection System Testing Verifying the performance of relay settings and other protection mechanisms that safeguard the transformer during fault conditions.

Conclusion

The thorough testing and commissioning of power transformers are essential for maintaining reliability in power systems. By adhering to established testing protocols and standards, utilities can mitigate risks, avoid costly failures, and ensure the seamless delivery of electricity to consumers. Continuous advancements in testing technologies further enhance the ability to assess and monitor transformer health, ultimately contributing to a more resilient and efficient electrical infrastructure. Hence, both testing and commissioning are critical for achieving operational excellence in power transformer management.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024