English

English

Power Transformer Assessment Procedures for Testing and Initial Activation

Power Transformer Testing and Commissioning Ensuring Reliability and Efficiency

Power transformers play a crucial role in electrical power systems by stepping up or stepping down voltage levels, thereby facilitating the efficient transmission and distribution of electricity. Given their importance, the testing and commissioning of these transformers are vital to ensure their reliability and efficiency throughout their operational life. This article explores the key aspects of power transformer testing and commissioning, highlighting the procedures, benefits, and best practices involved.

Understanding Transformer Testing

Vendor performance and quality assurance begin even before the transformer is installed. Factory acceptance tests (FAT) are conducted to verify that the transformer meets the specified design criteria. These tests include insulation resistance, power factor tests, and temperature rise tests, among others. These initial tests help to ensure that the equipment is built to the required standards and will function correctly upon installation.

Once the transformer is delivered to the site, additional tests are performed as part of the site acceptance tests (SAT). These tests often include insulation resistance measurements, transformer turns ratios (TTR), and sweep frequency response analysis. SAT helps in diagnosing any potential issues before the transformer is energized, ensuring a smooth transition into operation.

Commissioning Process

The commissioning of power transformers involves a systematic approach that includes the installation, testing, and validation of equipment. The process begins with a thorough review of installation procedures to ensure compliance with industry standards. During installation, visual inspections are crucial to identify any physical damage or incorrect installation practices.

Once the installation is confirmed to be correct, the commissioning tests are conducted. The tests include

1. Insulation Test Ensuring the integrity of insulation materials, which safeguards against electrical failures. 2. Transformer Turns Ratio (TTR) Test Verifying the turns ratio between the primary and secondary windings, crucial for voltage regulation.

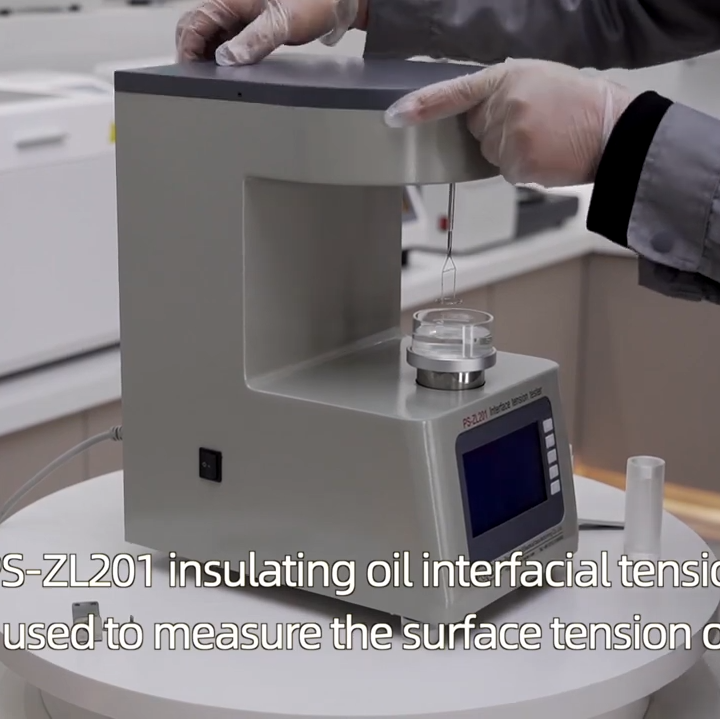

3. Power Factor Testing Assessing the dielectric losses in the insulating materials, which can indicate the condition of insulation.

power transformer testing and commissioning pdf

5. Functional Testing Ensures that all protective devices and control systems operate as intended.

Benefits of Effective Testing and Commissioning

The main benefit of a comprehensive testing and commissioning process is increased reliability. By identifying and addressing issues before the transformer is put into service, utilities can significantly reduce the risk of future failures, which can lead to costly outages and repair expenses.

Moreover, proper commissioning ensures that the transformer operates at optimal efficiency. Transformers are designed for specific loads and conditions, and thorough testing can validate performance metrics, preventing energy losses and minimizing operational costs.

Best Practices for Power Transformer Testing and Commissioning

1. Adhere to Standards Follow recommended guidelines from organizations such as IEEE and IEC to ensure industry best practices are upheld.

2. Invest in Training Ensure that personnel involved in testing and commissioning are well-trained and knowledgeable about transformer technology and testing methodologies.

3. Documentation Keep detailed records of all tests performed, including results and remediation actions taken, to ensure compliance and facilitate future maintenance.

4. Continuous Monitoring Implement a consistent monitoring program after commissioning to track performance and detect potential issues before they escalate.

In conclusion, the testing and commissioning of power transformers are integral to the reliability and efficiency of electrical power systems. By adhering to rigorous testing standards, utilities and operators can ensure that transformers operate safely and effectively throughout their service life, ultimately benefiting the broader power grid.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024