English

English

PPM Testing Procedures for Evaluating Transformer Oil Quality and Performance

PPM Test for Transformer Oil Ensuring Equipment Reliability

Transformers play a vital role in the electrical grid by stepping up or stepping down voltage levels to ensure efficient power distribution. However, as with any critical equipment, maintaining the reliability of transformers is essential. One aspect of preventive maintenance involves monitoring the condition of transformer oil, which acts as both an insulator and a cooling medium. The Parts Per Million (PPM) test for transformer oil is a key procedure used to measure the concentration of contaminants, ensuring the longevity and effectiveness of these essential devices.

PPM Test for Transformer Oil Ensuring Equipment Reliability

Water, one of the most detrimental contaminants in transformer oil, can lead to reduced insulation properties and accelerated aging of the oil and transformer components. The presence of moisture reduces the dielectric strength of the oil, increasing the risk of electrical failures. Testing for PPM levels allows for the early detection of water content, and if levels exceed acceptable limits, dewatering processes or oil replacement can be initiated.

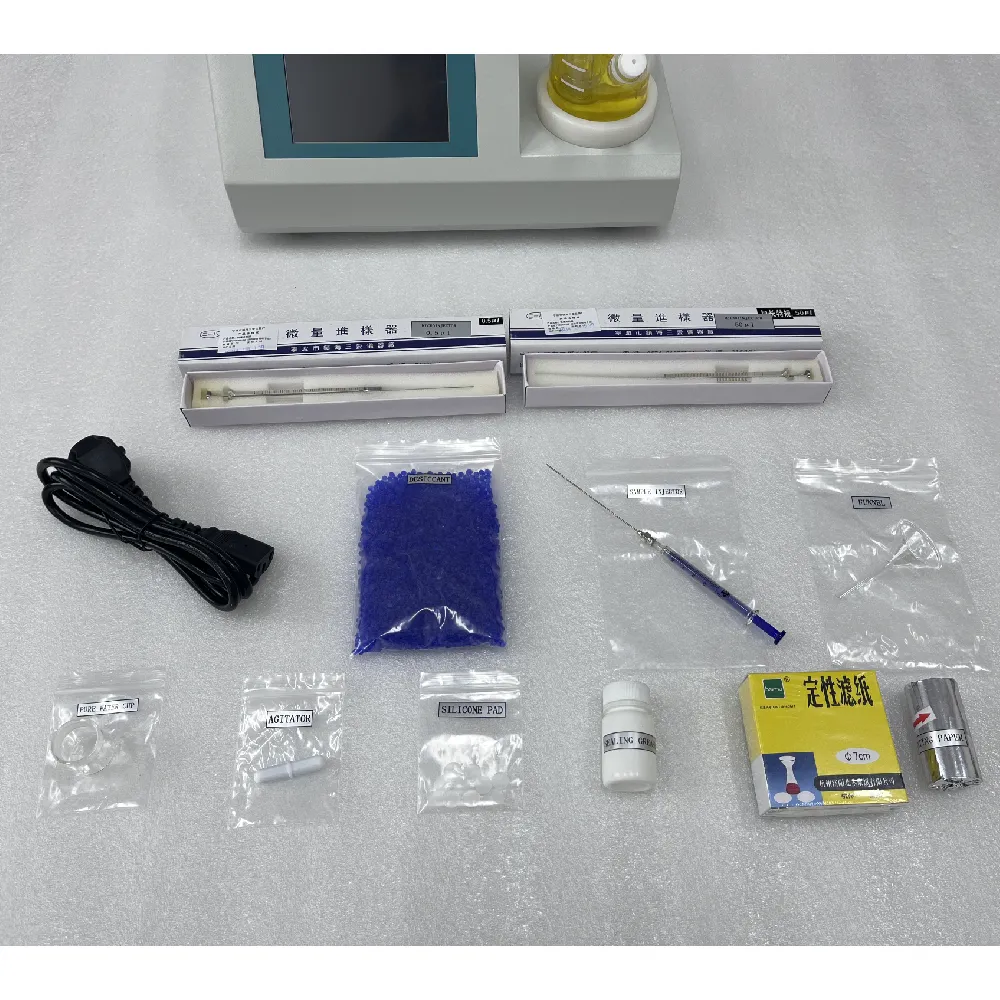

ppm test for transformer oil

In addition to moisture, particulate matter such as dirt, dust, and metal particles can enter the transformer oil, leading to increased wear and tear on the transformer windings. The PPM test quantifies these particulates, helping maintenance teams make informed decisions regarding filtration or other remedial actions. Contaminated oil not only affects performance but can also lead to catastrophic failures if left unaddressed.

Furthermore, the PPM test can assess the concentration of dissolved gases, which serve as indicators of internal problems like overheating and arcing. By monitoring gas levels, maintenance teams can identify potential transformer faults early, minimizing downtime and repair costs.

To conduct the PPM test, oil samples are typically collected and analyzed using sophisticated laboratory equipment. The results guide maintenance strategies and help in planning oil filtration, reclamation, or replacement activities.

In conclusion, the PPM test for transformer oil is a crucial component in ensuring the reliability and efficiency of transformer operations. Regular monitoring helps detect contaminants that can lead to performance degradation and potential failures. By investing in regular PPM testing and subsequent maintenance actions, utility companies can enhance the longevity of their transformers, ensuring a stable electrical supply for consumers.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024