English

English

Optimizing Performance in Gas Chromatography Systems for Enhanced Process Analysis

Understanding Process Gas Chromatography A Comprehensive Overview

Process gas chromatography (PGC) is an analytical technique used to separate and analyze gases in a mixture. This sophisticated method is pivotal in various industries, from petrochemicals to environmental monitoring, providing critical data for quality control, regulatory compliance, and research. In this article, we will delve into the fundamentals of process gas chromatography, its applications, advantages, and the key components involved in the system.

The Basics of Gas Chromatography

Gas chromatography is a technique that separates volatile compounds based on their different affinities to a stationary phase and a mobile phase. In a typical gas chromatographic setup, a sample is injected into a column where it is transported by an inert carrier gas, usually helium or nitrogen. As the mixture travels through the column, individual components interact with the stationary phase, leading to their separation based on their volatility and chemical properties.

In the context of process applications, the term process gas chromatography specifically refers to the use of this technique for continuous monitoring of gas samples taken directly from a process line. This real-time analysis is crucial for optimizing processes in various industries.

Key Applications of Process Gas Chromatography

1. Petroleum and Natural Gas Industry PGC is extensively used for analyzing hydrocarbons and impurities in natural gas streams. By identifying the composition of gases, operators can optimize production processes, ensure compliance with environmental regulations, and enhance safety measures.

2. Chemical Manufacturing In chemical production processes, PGC helps in monitoring byproducts and ensuring the purity of reactants. By understanding the gas composition, manufacturers can adjust parameters to maintain product quality and minimize waste.

3. Environmental Monitoring Process gas chromatography plays a vital role in detecting pollutants in the atmosphere. It is used to measure greenhouse gases, volatile organic compounds (VOCs), and other emissions that can impact air quality and contribute to climate change.

4. Food and Beverage Industry In the food and beverage sector, PGC is utilized for quality assurance and control. For example, it can identify flavor compounds in aroma profiles or detect unwanted contaminants that may affect product safety and quality.

Benefits of Process Gas Chromatography

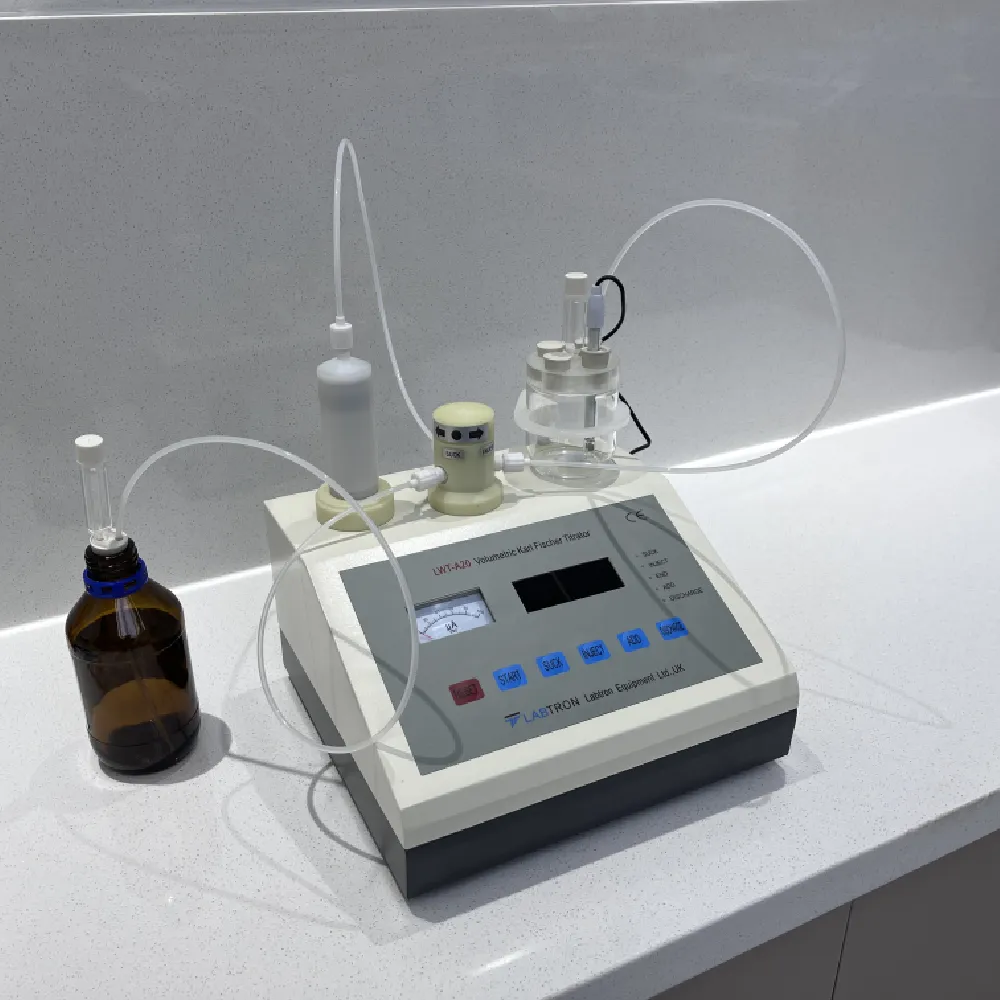

process gas chromatograph

One of the main advantages of PGC is its ability to provide high-resolution separation of complex gas mixtures. This feature is essential for industries where even trace amounts of a compound can impact product quality or safety. Additionally, PGC allows for continuous monitoring, enabling real-time data collection and immediate adjustments to processes. This capability not only improves efficiency but also enhances safety by providing early detection of hazardous compounds.

Moreover, the sensitivity of gas chromatographic detectors means that PGC can operate effectively even at very low concentration levels. This is particularly important in applications such as environmental monitoring, where regulatory standards often require detection of pollutants at trace levels.

Components of a Process Gas Chromatograph

A typical process gas chromatograph consists of several key components

1. Sample Injector This is where the gas sample is introduced into the system. It can be designed for manual or automatic operation.

2. Column The heart of the chromatograph, the column is where the actual separation of gases occurs. Columns can vary in length, diameter, and packing material depending on the application.

3. Carrier Gas System The inert gas (helium or nitrogen) that carries the sample through the column. The choice of carrier gas affects the efficiency and speed of the analysis.

4. Detector After gases exit the column, they are detected using various types of detectors, such as flame ionization detectors (FID) or thermal conductivity detectors (TCD), which quantify the components and generate a chromatogram.

5. Data Processing System This component processes the signal from the detector, generating quantitative and qualitative data that can be analyzed and interpreted.

Conclusion

Process gas chromatography is an invaluable tool across various fields, providing insights that drive optimization, compliance, and safety in industrial processes. Whether it's ensuring the purity of materials in chemical production or monitoring environmental pollutants, PGC continues to evolve, integrating advancements in technology to meet the ever-growing demands of industry and regulation. The ongoing development in methodologies and equipment will further enhance its capabilities, solidifying its role as a cornerstone of analytical chemistry in the process industries.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024