English

English

Regular Assessment of Transformer Performance Through Periodic Condition Monitoring Tests

Periodic Condition Monitoring Tests of Transformers

Transformers play a crucial role in the electrical power distribution and transmission systems, acting as devices that step up or step down voltage levels to ensure that electricity can be efficiently transported over long distances. Preventive maintenance of transformers, particularly through periodic condition monitoring tests, is essential to ensure their reliability and longevity. This article discusses the importance of these tests, common methodologies, and the benefits they provide.

Importance of Condition Monitoring

The primary goal of periodic condition monitoring is to identify potential failures before they occur. Transformers may experience various issues, such as insulation degradation, mechanical defects, or overheating, which can lead to costly outages and repairs. By implementing regular monitoring, utilities can not only enhance the reliability of their power systems but also optimize maintenance schedules, leading to reduced operational costs.

Common Condition Monitoring Tests

1. Dissolved Gas Analysis (DGA) This test detects the presence of gases dissolved in transformer oil. The type and concentration of gases can indicate specific issues; for example, the presence of acetylene may suggest arcing, while ethylene could point to overheating. Regular DGA assessments allow for early detection of insulation failure or overheating.

2. Insulation Resistance Testing By measuring the resistance of the transformer's insulation system, this test identifies potential weaknesses that could lead to electrical failures. A notable drop in insulation resistance over time can signal moisture ingress or deterioration, necessitating further investigation.

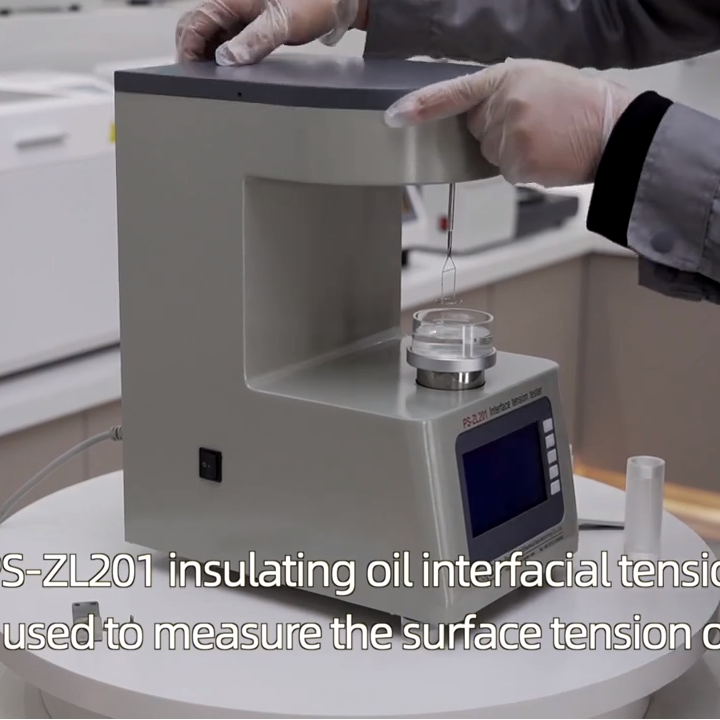

3. Power Factor Testing This evaluates the insulation quality within the transformer. A decreased power factor can indicate the insulation is aging and losing its effectiveness, allowing for early intervention to prevent future failures.

periodic condition monitoring tests of transformer

4. Thermal Imaging This non-invasive technique involves using infrared cameras to detect hot spots on transformers. Identifying and addressing these hot spots can prevent overheating and extend the equipment’s lifespan.

5. Circuit Breaker Analysis The functionality of circuit breakers associated with transformers is critical. Periodic testing ensures that they operate correctly under fault conditions. Testing includes mechanical inspections, contact resistance measurements, and timing analysis.

Benefits of Periodic Monitoring

Implementing a regular condition monitoring program offers several advantages. First and foremost, it significantly reduces the risk of unexpected failures. By detecting potential issues early, stakeholders can make informed decisions regarding repairs and maintenance, avoiding unplanned outages.

Moreover, these tests enhance the understanding of a transformer's operational health, contributing to more effective asset management. Utilities can prioritize maintenance efforts based on actual conditions rather than relying on generic schedules, leading to better resource allocation.

Additionally, condition monitoring supports compliance with regulatory standards and enhances safety by minimizing risks associated with transformer failures. It safeguards both personnel and equipment, ensuring a stable power supply for consumers.

Conclusion

Periodic condition monitoring tests of transformers are not just a means of ensuring operational efficiency; they are essential to the reliability of the entire power distribution network. Through techniques like dissolved gas analysis, insulation resistance testing, and thermal imaging, utilities can proactively manage transformer health and address issues before they escalate. As the demand for reliable power continues to grow, so does the need for effective maintenance strategies, making condition monitoring a critical component of modern electrical infrastructure management.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024