English

English

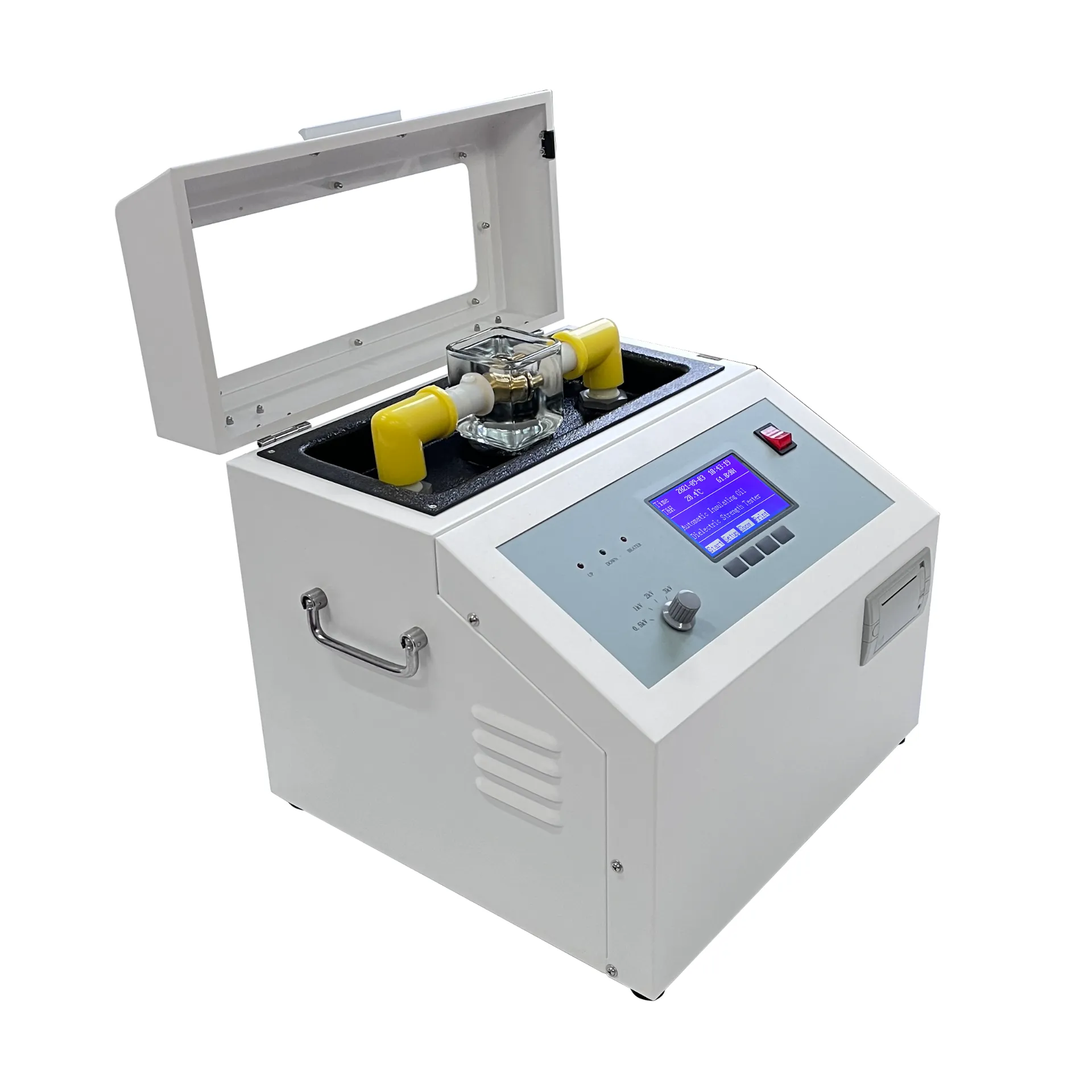

Electrical Resistance Testing Device for Accurate Measurement and Analysis

Understanding Resistance Testers in Electrical Applications

In the world of electrical engineering and maintenance, ensuring the reliability and safety of electrical systems is paramount. One of the essential tools for achieving this is the resistance tester. This device plays a crucial role in assessing the integrity of electrical components, ensuring that they function correctly and safely.

A resistance tester, often referred to as a megohmmeter or insulation resistance tester, measures the resistance of electrical circuits or insulation materials. Its primary function is to verify the insulation quality of wiring and components. Understanding how to use a resistance tester effectively can significantly enhance maintenance practices and safety standards.

Importance of Resistance Testing

Resistance testing is vital in various applications, including industrial electrical systems, residential wiring, and electronic devices. Over time, insulation materials can degrade due to environmental factors, electrical stress, or mechanical wear. This degradation can lead to increased resistance, which, in turn, can cause overheating or even electrical failures. By regularly using resistance testers, professionals can identify potential issues before they escalate into serious problems.

Types of Resistance Testers

There are several types of resistance testers, each designed for specific applications

. The most common types include1. Analog Resistance Testers These devices use a needle dial to indicate resistance levels. While they are relatively simple to use, they may not provide the precision required for modern electrical systems.

resistance tester electrical

2. Digital Resistance Testers These testers offer a digital readout, which enhances accuracy and ease of use. Many models include features such as data logging, allowing professionals to track resistance changes over time.

3. Insulation Resistance Testers These specialized testers apply a high voltage (usually 250V, 500V, or 1000V) to measure insulation resistance. This is particularly important for ensuring that high-voltage equipment is safe to operate.

Using a Resistance Tester

To use a resistance tester, one must first ensure that the equipment is de-energized and disconnected from any power sources. This safety precaution helps prevent electric shock and ensures accurate readings. The tester leads are then connected to the circuit or insulation being tested. After selecting the appropriate voltage level, the tester is activated, and the resistance value is displayed.

It’s important to interpret the results correctly. Generally, higher resistance values (measured in megohms) indicate better insulation quality. Conversely, low resistance values may suggest insulation breakdown or moisture ingress, which requires immediate attention.

Conclusion

In conclusion, resistance testers are indispensable tools in the field of electrical maintenance and safety. By providing accurate measurements of resistance, they help identify potential issues with insulation and wiring, thereby preventing costly failures and enhancing safety. As technology continues to advance, so too will the capabilities of resistance testers, further empowering electricians and engineers in their crucial work. Regular testing, combined with the proper understanding of resistance measurement, is key to maintaining safe and efficient electrical systems.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024