TEL:

+86-0312-3189593

English

English

Telephone:0312-3189593

Email:sales@oil-tester.com

1 月 . 20, 2025 11:41

Back to list

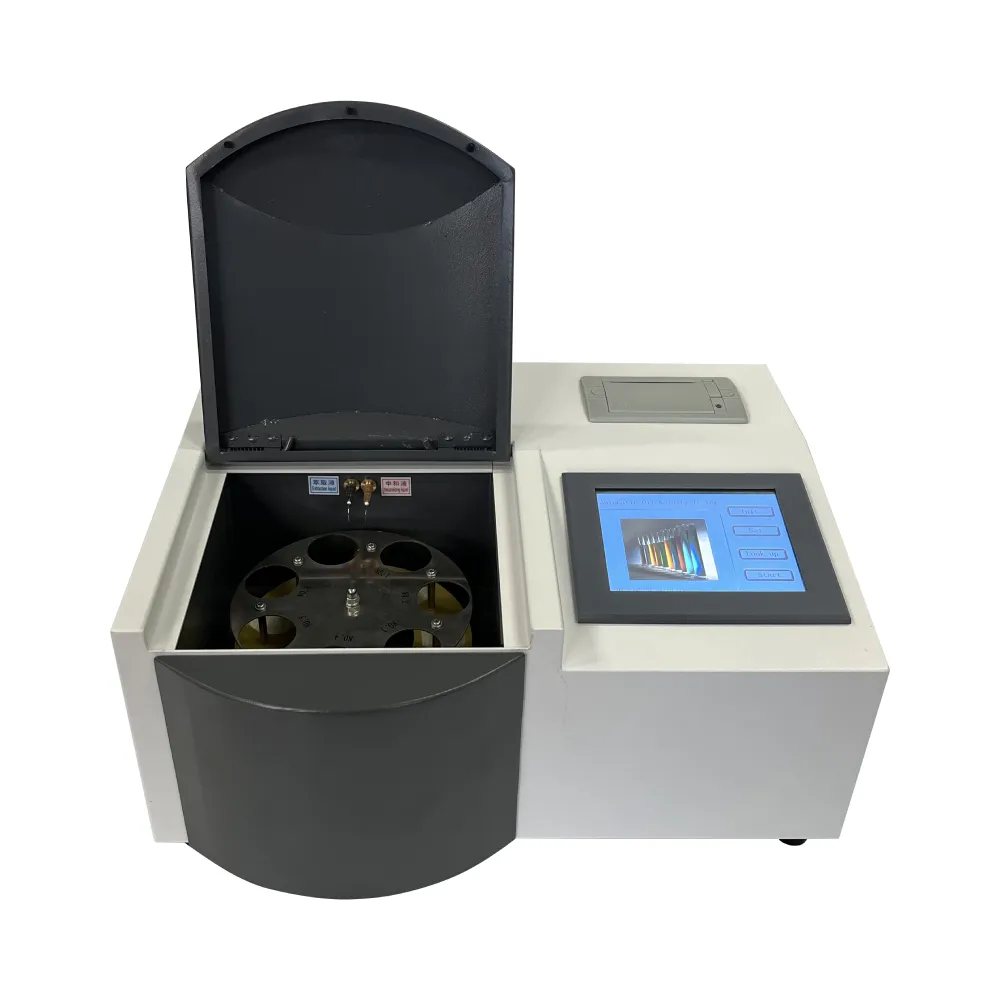

surface tension measurement device

In the intricate realm of scientific research and industrial applications, surface tension measurement devices form the backbone of numerous experiments and processes. As someone deeply embedded in the field, I can assert that choosing the right device not only enhances the accuracy of results but also boosts efficiency and reliability across varied applications.

The versatility of surface tension measurement devices cannot be overstated. These instruments are not restricted to liquid-only applications; they extend their utility to studying the properties of solutions, suspensions, and even solid materials when considering contact angles. This multifaceted capability makes them indispensable in research laboratories focusing on material science and nanotechnology. By understanding how different materials interact on a microscopic level, researchers can unlock new possibilities in developing advanced materials with desirable properties such as hydrophobicity or enhanced electrical conductivity. Safety and compliance also come into play when selecting a surface tension measurement device. Given the high-stakes environments in which these devices operate, adhering to international safety standards is non-negotiable. Devices embedded with features like automatic calibration, spill-proof designs, and user-guided protocols enhance operational safety and contribute to minimizing human error. This encapsulates the industry’s broader move towards promoting safety while maintaining high performance. Finally, the impact of a robust surface tension measurement device extends to environmental stewardship. By enabling precise formulation and minimizing waste, these devices support sustainable manufacturing practices. In an era where environmental responsibility is as crucial as economic profitability, investing in such devices aligns businesses with global sustainability goals. In conclusion, the choice of a surface tension measurement device is a cornerstone of operational excellence across multiple industries. With applications ranging from facilitating pharmaceutical excellence to promoting sustainable manufacturing practices, these devices offer unparalleled advantages in terms of precision, efficiency, and reliability. By prioritizing these instruments, industries not only adhere to high standards of expertise and trustworthiness but also drive innovation and sustainability forward.

The versatility of surface tension measurement devices cannot be overstated. These instruments are not restricted to liquid-only applications; they extend their utility to studying the properties of solutions, suspensions, and even solid materials when considering contact angles. This multifaceted capability makes them indispensable in research laboratories focusing on material science and nanotechnology. By understanding how different materials interact on a microscopic level, researchers can unlock new possibilities in developing advanced materials with desirable properties such as hydrophobicity or enhanced electrical conductivity. Safety and compliance also come into play when selecting a surface tension measurement device. Given the high-stakes environments in which these devices operate, adhering to international safety standards is non-negotiable. Devices embedded with features like automatic calibration, spill-proof designs, and user-guided protocols enhance operational safety and contribute to minimizing human error. This encapsulates the industry’s broader move towards promoting safety while maintaining high performance. Finally, the impact of a robust surface tension measurement device extends to environmental stewardship. By enabling precise formulation and minimizing waste, these devices support sustainable manufacturing practices. In an era where environmental responsibility is as crucial as economic profitability, investing in such devices aligns businesses with global sustainability goals. In conclusion, the choice of a surface tension measurement device is a cornerstone of operational excellence across multiple industries. With applications ranging from facilitating pharmaceutical excellence to promoting sustainable manufacturing practices, these devices offer unparalleled advantages in terms of precision, efficiency, and reliability. By prioritizing these instruments, industries not only adhere to high standards of expertise and trustworthiness but also drive innovation and sustainability forward.

Previous:

Latest news

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024