English

English

tan delta test for ct

Understanding the Tan Delta Test for Capacitor Testing

The Tan Delta test, also known as the Power Factor test or Dissipation Factor test, is an essential diagnostic tool in the field of electrical engineering, particularly for assessing the condition of capacitors used in electrical equipment. This test plays a crucial role in the maintenance of high voltage insulation systems, such as those found in transformers, generators, motors, and various types of cables. By measuring the dielectric losses in insulation materials, the Tan Delta test helps ensure the reliability and safety of electrical systems.

What is Tan Delta?

The term Tan Delta refers to the tangent of the loss angle (delta) in an insulation system. In simpler terms, it represents the ratio of the resistive component (real power losses) to the reactive component (stored energy) in a capacitor. The formula is given by

\[ \text{Tan} \, \delta = \frac{R}{X} \]

where \( R \) is the resistance through which power is lost, and \( X \) is the reactance associated with the capacitive component. A low Tan Delta value indicates that the dielectric material is functioning efficiently, absorbing minimal energy as heat, while a high Tan Delta value signifies deteriorating insulation properties and potentially excessive energy losses.

Why Conduct a Tan Delta Test?

1. Condition Monitoring The Tan Delta test is primarily used to assess the condition of insulation materials in electrical equipment. As insulation degrades due to factors such as aging, temperature fluctuations, humidity, and electrical stress, the Tan Delta value increases. Regular monitoring helps identify potential failures before they lead to catastrophic breakdowns.

2. Predictive Maintenance By establishing a baseline for the Tan Delta values in new installations, engineers can track changes over time. An increase in values can indicate developing problems, allowing for proactive maintenance interventions rather than reactive repairs. This predictive approach is more cost-effective and minimizes downtime.

3. Comparative Analysis The Tan Delta test allows for the comparison of insulation materials across different equipment types or manufacturers. This comparative analysis aids in decision-making when selecting materials for new installations or upgrades and justifying maintenance activities.

4. Safety Assurance Given the high voltages involved in many electrical systems, ensuring the integrity of insulation is critical. A failed capacitor can lead to system failures, electrical fires, or even safety hazards for personnel. Conducting Tan Delta tests routinely helps ensure safety and compliance with standards.

Performing the Tan Delta Test

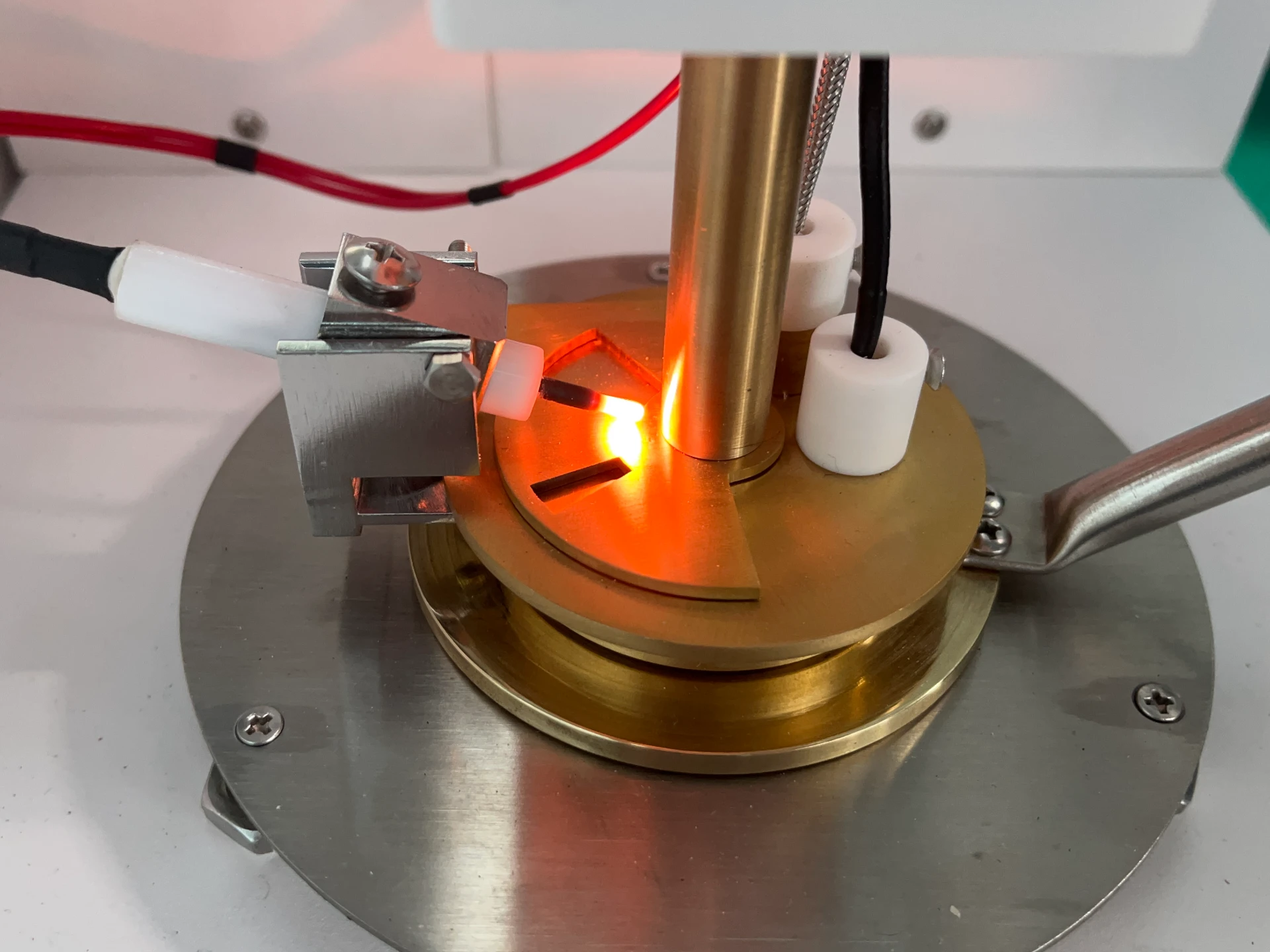

tan delta test for ct

The Tan Delta test requires specialized equipment, often referred to as a Tan Delta analyzer. The procedure typically involves the following steps

1. Preparation Isolate the capacitor or insulation system under test to ensure there is no influence from external currents. Ensure all safety protocols are strictly followed.

2. Testing Setup Connect the Tan Delta analyzer to the insulation system. The equipment applies a known AC voltage to the insulation under test while measuring the current flowing through the system.

3. Data Acquisition The analyzer calculates the Tan Delta value based on the measured current and voltage. Multiple readings may be taken to ensure accuracy and account for any anomalies.

4. Analysis Compare the obtained Tan Delta values against predetermined acceptable levels. A strategic approach often includes using values provided by manufacturers or industry standards for reference.

Interpreting Tan Delta Results

1. Low Values (0.001 - 0.005) Generally considered acceptable; the insulation system is in good condition.

2. Moderate Values (0.005 - 0.01) Indicates some degradation; further investigation may be warranted.

3. High Values (Above 0.01) Signals significant insulation deterioration; immediate action may be required to avoid equipment failure.

Conclusion

The Tan Delta test is a vital tool for evaluating the health of electrical insulation systems and ensuring the reliability of high voltage equipment. By understanding its principles, implementation, and significance, electrical engineers can enhance maintenance strategies, prevent costly failures, and ultimately safeguard the efficiency and safety of electrical networks. Regular Tan Delta testing is an investment in the longevity and performance of electrical systems, crucial in today’s reliability-driven industrial landscape.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024