English

English

Evaluating Tan Delta Test for Capacitor Voltage Transformers in Electrical Applications

Understanding Tan Delta Testing of Capacitor Voltage Transformers (CVTs)

Capacitor Voltage Transformers (CVTs) play a vital role in electrical power systems. Their primary function is to step down high voltage signals to a lower, manageable level for measurement and protection purposes. To ensure that these devices operate effectively and safely, it’s essential to conduct thorough testing, one of which is the Tan Delta test.

The Tan Delta test, also known as the Power Factor test, is a diagnostic method used to assess the insulation condition of electrical components, particularly for CVTs. It measures the phase difference between the voltage across the insulation and the current flowing through it. Essentially, the tan delta value indicates how much insulation loss occurs; lower values signify better insulation quality.

Principles of the Tan Delta Test

The test is based on the principle of dielectric dissipation. When an AC voltage is applied to the CVT, the insulation has a capacitive behavior. However, imperfections within the insulation can cause some energy to be lost as heat, characterized by the power factor or dissipation factor, often expressed as tan delta (δ). This can be seen as a parametric measurement where the angle between the voltage and current waveforms is analyzed.

A tan delta value of 0.1 or lower is typically considered acceptable in most applications. As the value increases, it suggests the presence of moisture, contamination, or deterioration of the insulating material, which can lead to premature failure or operational issues. Thus, keeping a regular check on tan delta can significantly enhance the reliability of electrical systems.

Conducting the Tan Delta Test

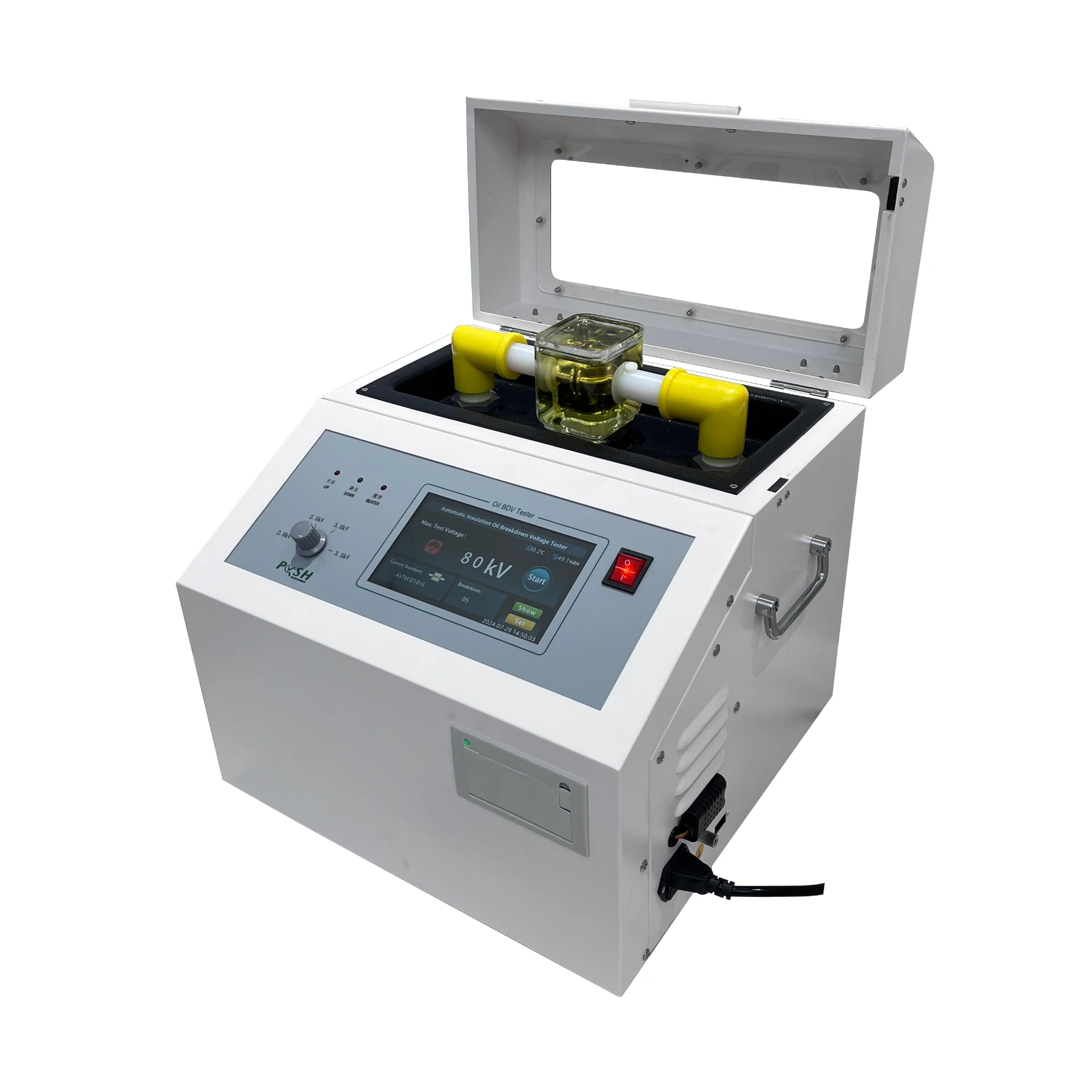

tan delta test of cvt

Performing a Tan Delta test involves using a specialized instrument, usually an insulation resistance tester equipped with a tan delta measurement option

. The procedure primarily requires the following steps1. Preparation Ensure the CVT is isolated from the power system and all safety protocols are followed. 2. Connection Connect the testing equipment as per the manufacturer’s guidelines. This usually involves connecting the device to both the primary and secondary terminals of the CVT.

3. Execution Apply the test voltage, typically at the rated voltage of the CVT. The instrument will then measure the capacitance and the phase angle between voltage and current.

4. Analysis The results will yield a tan delta value, which should be compared against the acceptable limits. A higher value might indicate the need for further inspection or preventive maintenance.

Conclusion

The Tan Delta test is indispensable for maintaining the reliability and functionality of Capacitor Voltage Transformers in power systems. By regularly assessing the insulation integrity through tan delta measurements, utilities can preemptively address potential failures, ensuring uninterrupted and safe electrical distribution. As technology advances, the accuracy and efficiency of these tests continue to improve, making them a cornerstone of electrical maintenance practices. Ensuring that CVTs are in optimal condition not only protects the equipment but also safeguards the entire power system.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024