English

English

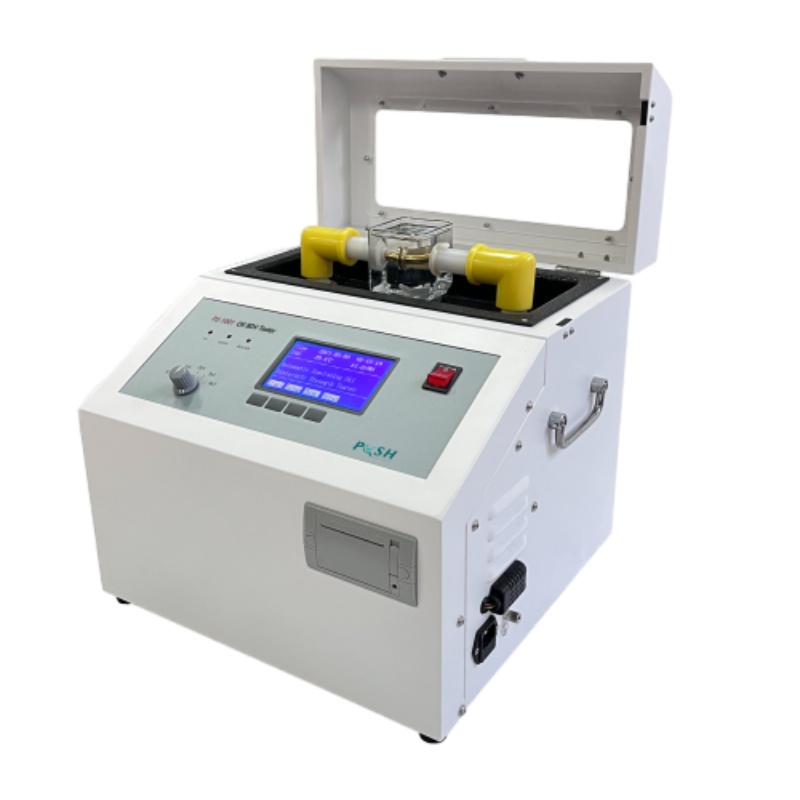

tangent delta test transformer

Understanding the Tangent Delta Test for Transformers

Transformers are essential components in electrical power systems, responsible for transferring electrical energy between circuits through electromagnetic induction. Ensuring the reliability and efficiency of transformers is critical, as they are often subjected to varying load conditions and environmental factors. One of the key tests utilized to assess the condition of insulation materials within transformers is the Tangent Delta (tan δ) test. This article explores the significance, methodology, and interpretation of the Tangent Delta test in transformer maintenance and condition assessment.

The Importance of Insulation

Insulation is vital in maintaining the operational integrity of transformers. It helps prevent electrical leaks and ensures that energy is efficiently transmitted. Over time, insulation materials may degrade due to thermal, electrical, and mechanical stresses, leading to increased risk of failure. A reliable way to assess the condition of these materials is through dielectric testing. The Tangent Delta test plays a crucial role in this assessment.

What is the Tangent Delta Test?

The Tangent Delta test measures the dielectric losses in insulation materials, providing insight into their condition. The term tangent delta refers to the ratio of the resistive current (loss current) to the capacitive current (charging current) in the transformer insulation. Mathematically, it is represented as

\[ \tan \delta = \frac{I_{\text{loss}}}{I_{\text{cap}}} \]

Where - \( I_{\text{loss}} \) is the resistive current, - \( I_{\text{cap}} \) is the capacitive current.

A higher tangent delta value indicates a greater level of dielectric losses, suggesting deterioration of the insulation material.

How is the Test Conducted?

The Tangent Delta test can be performed on both new and in-service transformers. The procedure typically involves the following steps

tangent delta test transformer

2. Test Setup Test equipment, including a test voltage source and an appropriate measurement system, is connected to the transformer. The test voltage is usually applied at rated frequency (50 or 60 Hz).

3. Measurement The test voltage is gradually increased to an appropriate level (often specified by industry standards), and the resulting currents are monitored. The tangent delta value is calculated from these current measurements.

4. Analysis The collected data is analyzed compared against historical data and industry benchmarks.

Interpreting the Results

The results from the Tangent Delta test are analyzed based on specific criteria. Generally, a tangent delta value of less than 0.01 is considered acceptable for new insulation. As transformers age or if insulation begins to deteriorate, the tangent delta value may increase.

- Tangent Delta ≤ 0.01 Indicates good insulation condition, minimal losses. - Tangent Delta 0.01 - 0.05 Suggests potential issues; further investigation may be required. - Tangent Delta > 0.05 Indicates significant degradation; urgent action is recommended to avoid failure.

Moreover, a comparative analysis of tangent delta values over time allows for trend analysis, enabling engineers to predict potential issues and schedule maintenance proactively.

Benefits of the Tangent Delta Test

The Tangent Delta test has several benefits that make it an essential tool in transformer maintenance

- Non-Destructive The test does not damage the transformer or its insulation materials, allowing for safe and repeated assessments. - Reflects Actual Condition It provides a direct measure of insulation condition rather than relying on theoretical calculations. - Early Detection By identifying insulation degradation early, operators can take preventive measures, reducing the risk of catastrophic failures and prolonging the transformer’s life.

Conclusion

In summary, the Tangent Delta test is a vital diagnostic tool for monitoring the condition of transformer insulation. By measuring dielectric losses, it helps assess the longevity and reliability of transformers in the electrical grid. The results from this test enable electrical engineers to make informed decisions about maintenance, thereby enhancing the overall operational efficiency of power systems. As technology continues to advance, the importance of proactive maintenance strategies, such as the Tangent Delta test, will only increase in the quest for a more reliable energy infrastructure.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024