English

English

test before commissioning of transformer

Testing Before Commissioning of Transformers

Transformers are essential components in electrical power systems, functioning to increase or decrease voltage levels between circuits while maintaining frequency. Before being commissioned for operational use, it is crucial to conduct various tests to ensure their reliability, safety, and efficiency. The comprehensive testing of transformers not only helps in identifying potential issues but also guarantees that they will perform correctly under expected conditions.

Importance of Pre-Commissioning Testing

Pre-commissioning testing serves several essential purposes. Firstly, it verifies that the transformer meets manufacturer specifications and industry standards. This includes measurements of electrical properties, insulation integrity, mechanical structure, and operational performance. Secondly, it identifies any manufacturing defects or damage that may have occurred during transportation and installation. This early detection can save organizations from costly downtime and maintenance following commissioning.

Key Tests Conducted

1. Insulation Resistance Testing This test examines the condition of the insulation system of the transformer. High insulation resistance values indicate that the insulating material is intact and will effectively prevent electrical leakage. A low resistance value may suggest moisture ingress, contamination, or physical damage, necessitating further inspection or remediation.

2. Transformer Turns Ratio Test (TTR) The turns ratio test evaluates the ratio of the primary to secondary winding turns. This is crucial because improper turns ratios can result in operational failures. A deviation from specified ratios may indicate possible winding issues or short circuits.

test before commissioning of transformer

3. Power Factor Testing This assessment provides insights into the dielectric losses in the insulation system. By measuring the power factor, technicians can determine the health of the insulating material. A high power factor indicates effective insulation, while an excessively low factor could signal a need for further investigation.

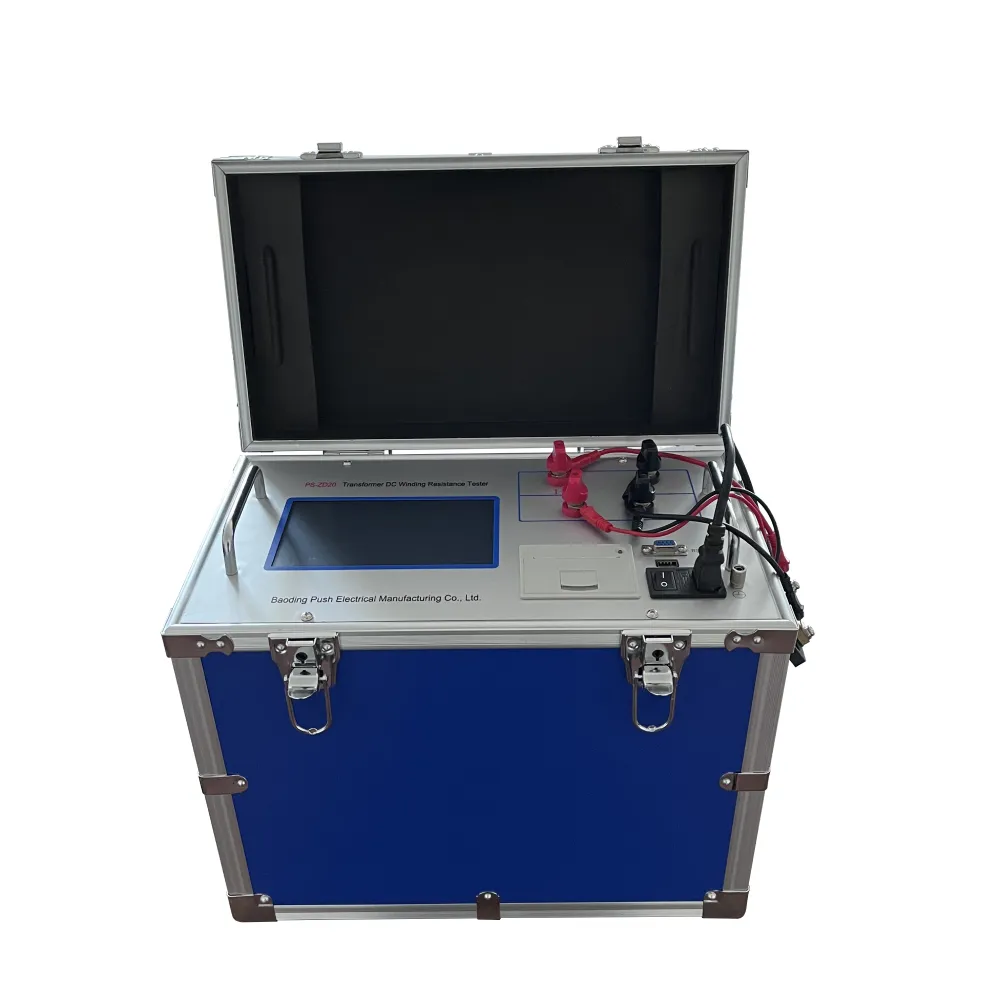

4. Winding Resistance Measurement This test assesses the resistance of the transformer windings. Variations in resistance can indicate issues such as uneven heating or deteriorating wire connections. Ensuring that the windings are within specified limits helps maintain operational efficiency and longevity.

5. Cooling System Evaluation Transformers operate under heavy loads, generating significant heat. Pre-commissioning testing includes checks on the cooling system, confirming adequate coolant levels, operational fans, and heat exchangers. Proper cooling is vital for maintaining optimal performance and preventing thermal overload.

6. Sweep Frequency Response Analysis (SFRA) SFRA is used to detect potential mechanical issues within the transformer, such as winding displacements or short circuits. By analyzing the frequency response, engineers can identify deviations that might indicate structural problems.

7. Circuit Breaker Testing Since transformers work in conjunction with circuit breakers, testing these components ensures that they will operate correctly during fault conditions, thus preventing equipment damage and enhancing system safety.

Conclusion

The pre-commissioning testing of transformers is an indispensable process in the electrical industry. By systematically carrying out a series of tests, companies can mitigate risks associated with transformer failure, ensure compliance with regulatory standards, and validate performance capabilities before the unit is put into operational service. Investing time and resources in thorough pre-commissioning is not merely a procedural necessity but a strategic approach to safeguarding assets and ensuring uninterrupted power supply. As the global demand for reliable electrical networks continues to grow, the significance of robust pre-commissioning practices will only increase, underscoring the necessity for diligent testing protocols in transformer management.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024