English

English

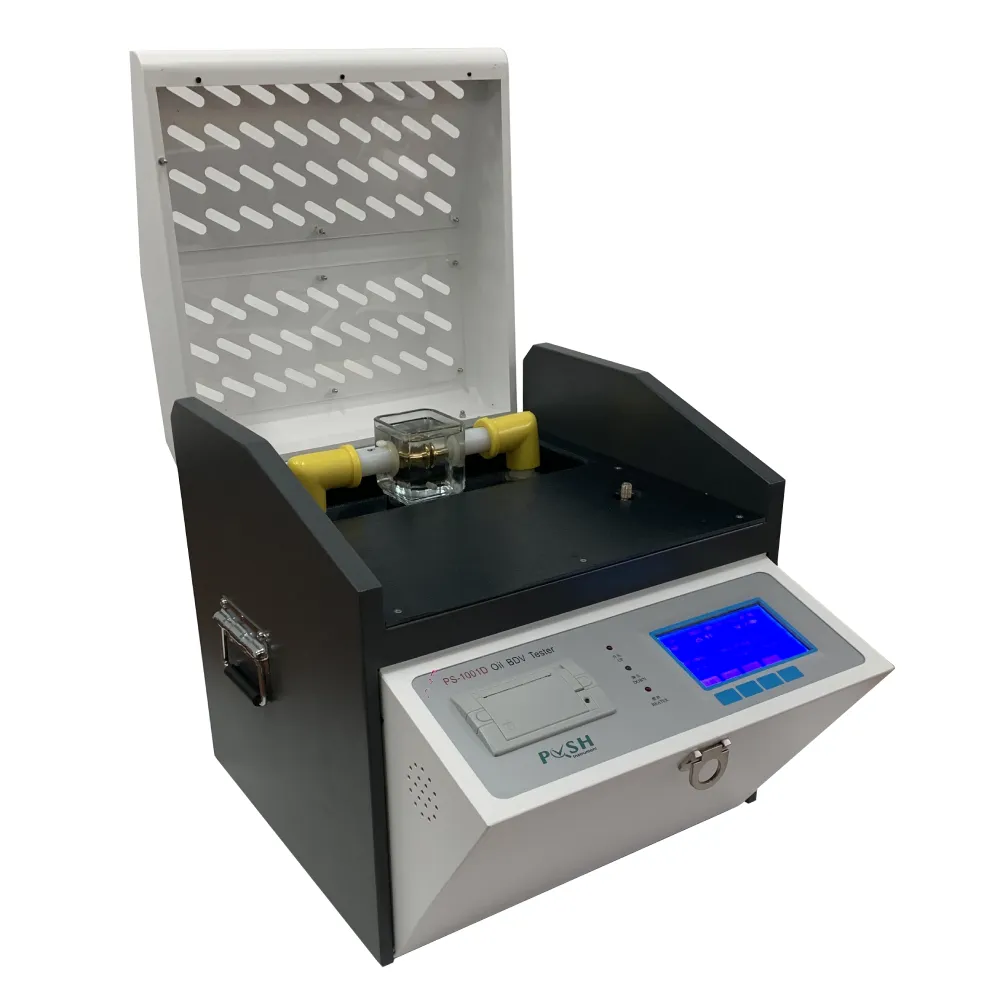

Testing Equipment for Transformer Oil Quality and Performance Assessment in Electrical Applications

Transformer Oil Testing Machine Ensuring Reliability in Electrical Systems

Transformer oil is a crucial component in electrical power systems, providing insulation and cooling for transformers. The effectiveness and longevity of transformer oil directly impact the reliability of the entire electrical grid. Consequently, the need for precise and reliable testing of transformer oil is essential. Enter the transformer oil testing machine—a vital tool in maintaining the health of electrical infrastructures.

Transformer oil testing machines are designed to assess various physical and chemical properties of transformer oil. These tests help identify any degradation or contamination within the oil, which can lead to significant failures if left unchecked. The primary tests conducted using these machines include Dissolved Gas Analysis (DGA), moisture content measurement, acidity testing, and dielectric breakdown voltage evaluation.

One of the most critical assessments performed is Dissolved Gas Analysis. Transformer oils can dissolve gases produced by internal faults and thermal degradation. By analyzing these gases, operators can diagnose the condition of the transformer and predict potential failures. A transformer oil testing machine equipped with advanced gas chromatographic capabilities can separate and quantify gases such as hydrogen, methane, ethane, and acetylene. This provides invaluable insights into the operational status of the transformer.

Moisture content is another vital parameter that must be monitored. Excess moisture in transformer oil can accelerate insulation breakdown and corrosion within the transformer. The testing machine uses Karl Fischer titration methods or capacitive sensors to measure moisture levels accurately. Regular testing can help in implementing preventive maintenance measures before the moisture content reaches critical levels.

transformer oil testing machine

Acidity is another significant factor in transformer oil health. Over time, the oil can become acidic due to oxidation, leading to insulation degradation and the formation of sludge. A transformer oil testing machine can provide pH and total acid number (TAN) measurements, helping operators determine when oil renewal or treatment is necessary.

Dielectric breakdown voltage is a crucial indicator of the insulating properties of transformer oil. A transformer with oil that has a low breakdown voltage can be susceptible to electrical faults and failures. Using the testing machine, operators can apply a high voltage to the oil sample and measure the breakdown voltage. Maintaining a high dielectric strength ensures that the transformer can safely handle operational voltages without risking failure.

The technological advancements in transformer oil testing machines have significantly enhanced their accuracy and efficiency. Modern machines are often automated, providing users with fast results and detailed reporting capabilities. They can store historical data to track changes over time, facilitating trend analysis and predictive maintenance strategies.

Moreover, many transformer oil testing machines are designed with user-friendly interfaces, making them accessible even for those who may not have extensive technical backgrounds. This democratization of technology ensures that more personnel can participate in routine oil assessment, fostering a culture of proactive maintenance within organizations.

In conclusion, transformer oil testing machines play an indispensable role in the management of electrical power systems. By providing reliable and accurate assessments of transformer oil, these machines help prevent costly failures and extend the lifespan of vital equipment. As electrical grids continue to expand and evolve, the importance of such testing mechanisms will only grow, ensuring that the backbone of our energy systems remains robust and efficient. Regular testing and maintenance, facilitated by advanced technology, are essential in safeguarding our modern infrastructure.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024