English

English

Evaluating the Performance of a Step-Down Transformer in Electrical Applications

Testing a Step-Down Transformer An Overview

Step-down transformers play a crucial role in electrical engineering, allowing for the conversion of a higher voltage to a lower voltage. These devices are essential in various applications, including power distribution, electronics, and industrial machinery. Testing a step-down transformer is vital to ensure its efficiency, safety, and reliability. This article explores the methods and significance of testing a step-down transformer.

Understanding Step-Down Transformers

A step-down transformer operates on the principle of electromagnetic induction. It consists of two coils—the primary winding, which receives the input voltage, and the secondary winding, which delivers the reduced output voltage. The transformer’s turns ratio determines the voltage reduction; for example, a transformer with a turns ratio of 101 will reduce the voltage to one-tenth of the input voltage. Proper testing of these transformers is essential to verify that they are functioning correctly.

Importance of Testing

Testing a step-down transformer is essential for several reasons. First, it ensures that the transformer operates within its designed specifications. If the output voltage deviates significantly from the expected value, it can lead to malfunctioning of connected devices or systems. Second, testing helps identify potential safety issues, such as overheating or electrical faults, that could pose risks to users and equipment. Finally, regular testing can help extend the lifespan of the transformer, as early detection of issues allows for timely maintenance or repairs.

Testing Procedures

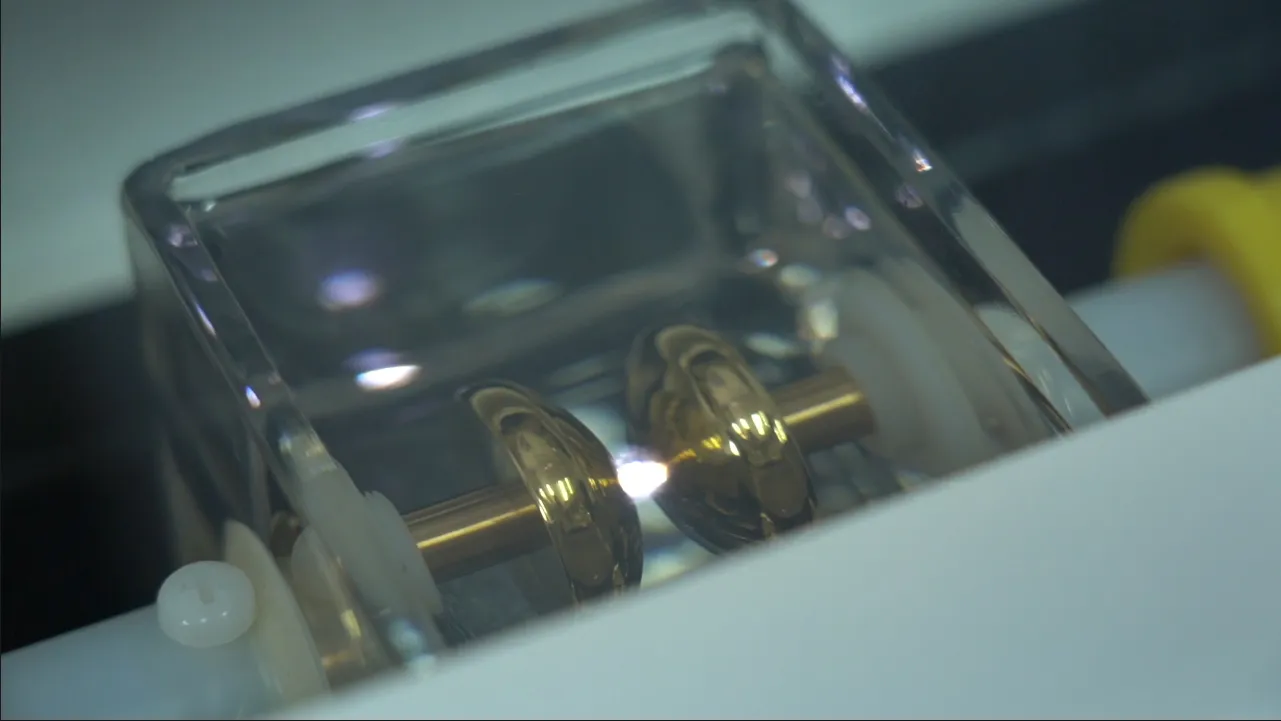

testing a step down transformer

1. Visual Inspection Before any electrical tests, a thorough visual inspection of the transformer is conducted. This involves checking for signs of physical damage, corrosion, and proper connections. Ensuring that the transformer is clean and well-maintained is crucial for accurate testing results.

2. Insulation Resistance Testing This test measures the insulation resistance between the windings and the ground. A megohmmeter is typically used for this purpose, and a high resistance value (usually in the megohm range) indicates good isolation, preventing short circuits or faults.

3. Turns Ratio Testing This test evaluates the ratio of the primary and secondary windings. A specialized turns ratio tester is used to ensure that the actual turns ratio matches the specified design ratio. Discrepancies can suggest problems with the windings or core.

4. Load Testing During load testing, the transformer is subjected to its nominal load to assess its performance under operational conditions. This test measures the output voltage, current, and efficiency, allowing engineers to determine if the transformer is capable of handling its expected load.

5. Thermal Imaging Utilizing infrared thermography can help identify hot spots in the transformer which may indicate potential failures. This non-invasive test allows for monitoring the temperature of components without interrupting service.

Conclusion

Testing a step-down transformer is a critical process that ensures the device's operational integrity, safety, and efficiency. Through a combination of visual inspections, insulation resistance testing, turns ratio assessments, load testing, and thermal imaging, engineers can diagnose issues and confirm that transformers perform as expected. Regular testing not only enhances safety but also contributes to the longevity of the equipment, making it a fundamental aspect of transformer maintenance and oversight in electrical engineering applications. Properly maintained and tested step-down transformers are essential for reliable power distribution and the smooth operation of electrical systems.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024