English

English

Tests Before Commissioning of Transformer, Induction Motor, and Alternator

Testing Before Commissioning of Transformers, Induction Motors, and Alternators

The commissioning phase of electrical equipment such as transformers, induction motors, and alternators is critical to ensuring their reliability and efficiency in operation. Prior to commissioning, comprehensive testing procedures must be conducted to verify the equipment’s performance and safety. This article outlines the key tests that should be performed on these vital components in an electrical system.

Transformers

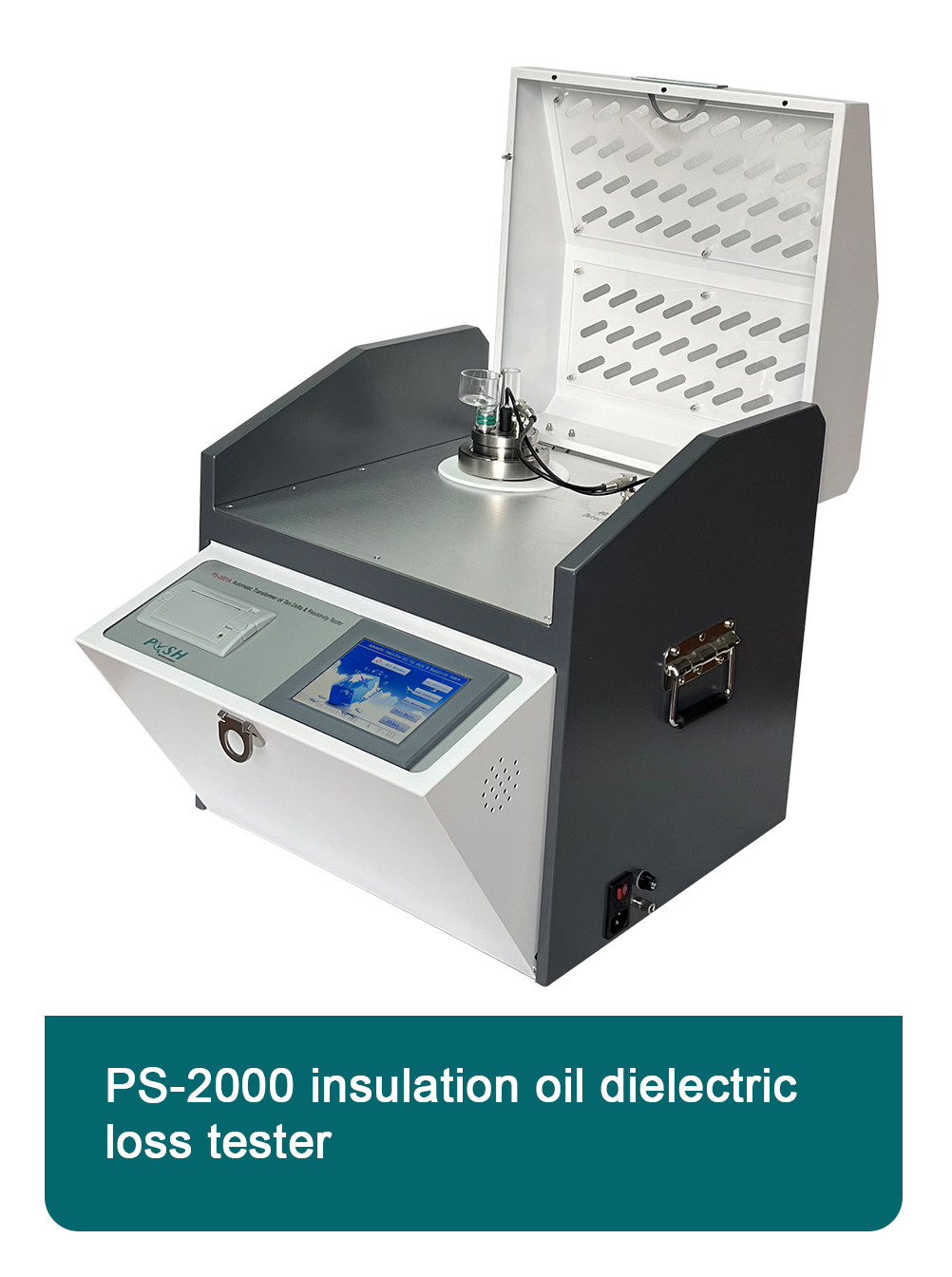

Transformers serve as essential devices for voltage regulation in power distribution. Before commissioning, various tests must be carried out to ensure their functionality. One of the primary tests is the insulation resistance test, which assesses the quality of insulation materials and safeguards against leakage currents. The turns ratio test follows, which compares the primary and secondary winding ratios and ensures that the transformer is functioning within specified limits. Additionally, power factor tests help identify any deterioration in insulation properties. The transformer should also undergo short-circuit and open-circuit tests to analyze its efficiency and losses under load conditions. These preliminary tests are crucial in ensuring that the transformer operates safely and effectively in the electrical network.

Induction Motors

tests before commissioning of transformer induction motor and alternator

Induction motors are widely used in industrial applications due to their robustness and reliability. Before an induction motor is commissioned, it is subjected to several tests. The most important is the insulation resistance test, aimed at detecting any insulation faults that could lead to short circuits. A no-load test measures the motor's characteristics when it is not under load, helping to evaluate its efficiency and rotor dynamics. During the locked rotor test, the motor is stalled to measure the starting torque and current, providing insights into its starting capabilities. Vibration and temperature analysis are also crucial, as excessive vibrations or temperatures can indicate underlying mechanical issues. These tests ensure that the induction motor is primed for reliable service in its application.

Alternators

As the primary source of electrical power generation in many setups, alternators must undergo rigorous testing before commissioning. The key tests for alternators include the open-circuit test, where the output voltage and frequency are measured without any load. Short-circuit tests are conducted to determine the machine's ability to handle fault conditions. Additionally, voltage regulation tests help assess how well the alternator can maintain output voltage under varying loads. A thorough inspection of the bearings and cooling system, alongside soundness checks for mechanical integrity, ensures that the alternator operates smoothly and efficiently.

In conclusion, the testing of transformers, induction motors, and alternators before commissioning is paramount to guarantee their reliability and performance. Through rigorous testing, potential issues can be identified and rectified, ultimately leading to safer and more efficient electrical systems. Proper commissioning not only prolongs the lifespan of electrical equipment but also ensures optimal functionality in diverse applications.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024