English

English

test tan delta

Understanding Test Tan Delta A Comprehensive Guide

Tan delta, also known as the dissipation factor or loss tangent, is a critical parameter in electrical engineering and materials science, particularly when assessing insulators and dielectric materials. It provides insights into how much energy is lost as heat in insulating materials. This article delves into the concept of tan delta, its significance, measurement techniques, and overall impact on electrical insulation systems.

What is Tan Delta?

The term tan delta originates from trigonometry, where it refers to the tangent of an angle in a right triangle. In the context of electrical engineering, tan delta is defined as the ratio of the resistive (or real) component to the reactive (or imaginary) component of the material's impedance. It is expressed mathematically as

\[ \text{tan } \delta = \frac{R}{X} \]

where \( R \) is the resistance and \( X \) is the reactance. This relationship indicates how much energy from the electric field is absorbed by the material, leading to dielectric losses. Essentially, a higher tan delta value signifies higher energy losses, which can point to deteriorating insulation or impending failure in electrical equipment.

Importance of Measuring Tan Delta

The measurement of tan delta is particularly crucial for evaluating the condition of electrical insulation in cables, transformers, and other high-voltage equipment. Regular testing can

1. Detect Insulation Degradation Over time, electrical insulation can suffer from wear and tear due to thermal stress, electrical stress, moisture ingress, and chemical exposure. An increase in tan delta readings often correlates with deteriorating insulation quality.

2. Prevent Failures By recognizing the early signs of insulation breakdown, maintenance teams can take proactive measures to mitigate failures, thereby avoiding costly downtime and ensuring safety.

test tan delta

3. Assess Material Quality Tan delta testing can also provide insights into the quality of raw materials used in insulation. Subpar materials can lead to higher loss values, which may not only affect performance but also result in financial implications.

4. Enhance Safety Insulation failure in high voltage applications can lead to catastrophic events, including fires and electrical accidents. Monitoring tan delta can help ensure that insulation continues to meet safety standards.

Measurement Techniques

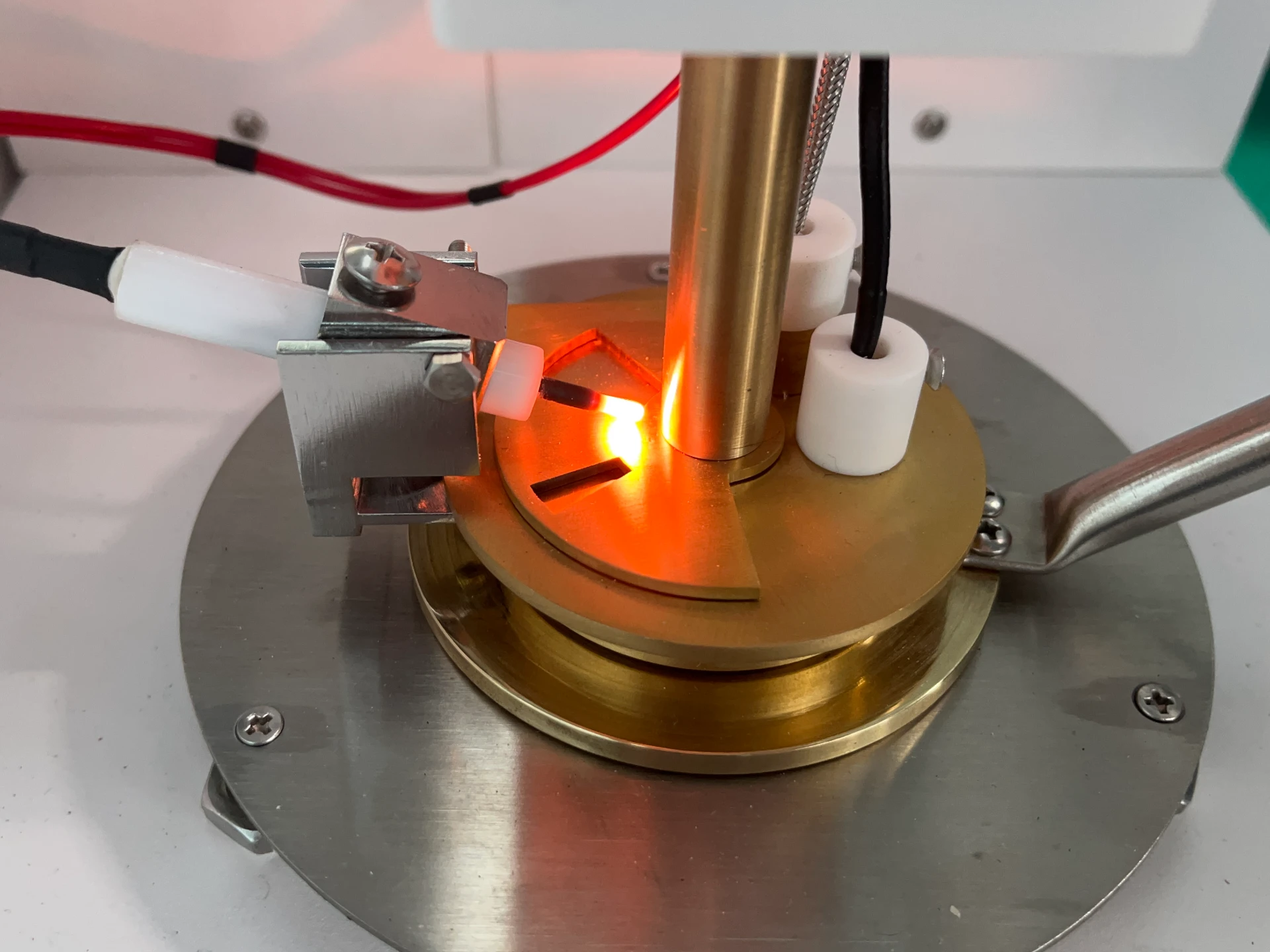

There are various methods to measure tan delta, with the most common being the use of a tan delta tester. This device applies an AC voltage to the insulation material, prompting it to behave like a capacitor. By measuring the current flow, the tester can calculate the tan delta value.

1. Capacitance and Power Factor Measurement This method involves measuring the capacitance of the insulation and the power factor, which can then be used to compute tan delta.

2. Bridge Methods Advanced setups use a bridge circuit that can accurately gauge small changes in capacitance and tangential current to deliver precise tan delta readings.

3. Frequency Dependency Tan delta values can change with frequency; therefore, it's essential to assess the measurement settings to ensure they reflect real operational conditions.

Conclusion

In summary, test tan delta is an essential diagnostic tool in the field of electrical engineering that provides significant insights into the condition of insulation materials. With its ability to reveal the health of electrical equipment, measuring tan delta is vital for preventing unexpected failures and ensuring the longevity and safety of electrical systems. Regular monitoring, combined with an understanding of the principles behind tan delta, enables engineers and maintenance personnel to make informed decisions and maintain efficient, safe operations in high voltage environments. By integrating tan delta testing into routine maintenance schedules, organizations can secure both performance and reliability in their electrical assets, thereby enhancing operational efficiency and safeguarding against costly disruptions.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024