English

English

Transformer oil inspection items and test significance

Appearance: Check the appearance of the running oil to find the presence of insoluble sludge, fiber and dirt in the oil. In routine tests, this item should be recorded.

Color: New transformer oil is generally colorless or light yellow, and the color will gradually deepen during operation, but under normal circumstances, this change trend is relatively slow. If the color of the oil product deepens sharply, it should be investigated whether the equipment is overloaded or overheated. If other relevant characteristic test items meet the requirements, it can continue to operate, but monitoring should be strengthened.

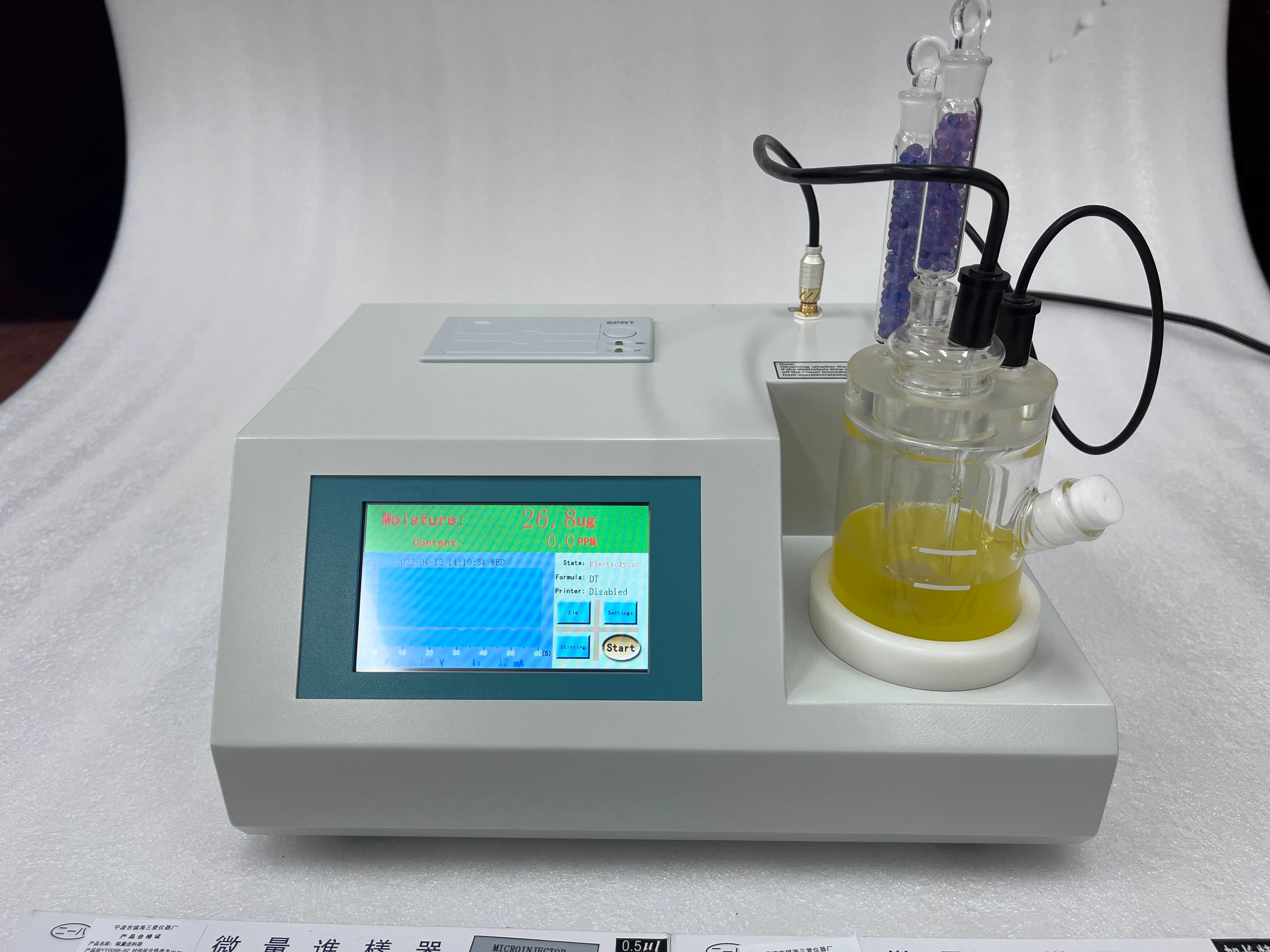

Moisture: Moisture is one of the important reasons affecting the insulation aging of transformer equipment. The increase in water content in transformer oil and insulating materials directly leads to a decrease in insulation performance and promotes oil aging, affecting the reliability and service life of equipment operation. Strict supervision of moisture is an essential test item to ensure the safe operation of equipment.

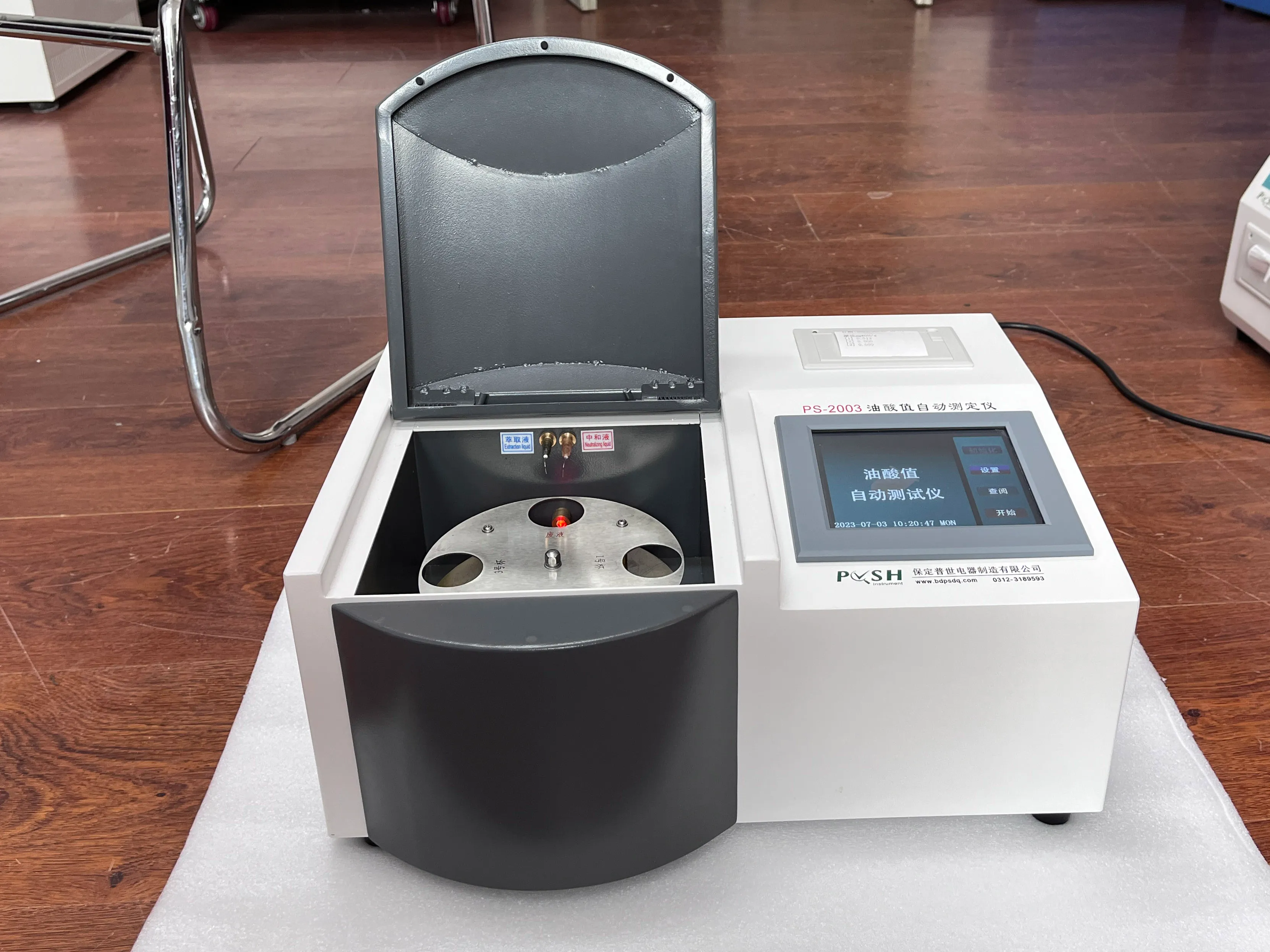

Acid value: The acidic products contained in the oil will increase the conductivity of the oil and reduce the insulation performance of the oil. When the operating temperature is high (such as above 80°C), it will also promote the aging and corrosion of solid fibrous insulation materials, shortening the service life of the equipment. Since the acid value in the oil can reflect the aging of the oil, it is important to strengthen the supervision of the acid value for taking correct maintenance measures.

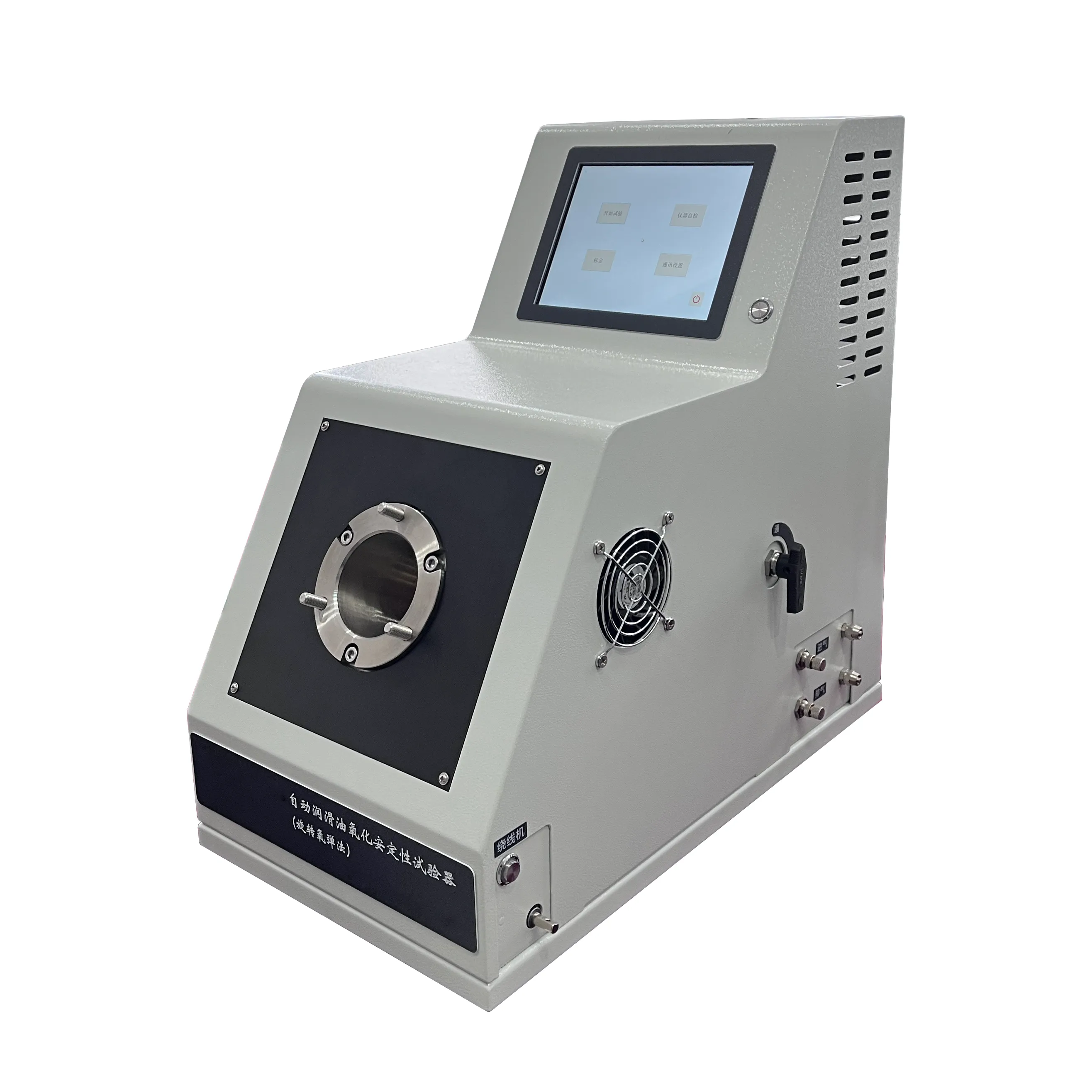

Oxidation stability: The oxidation stability test of transformer oil is an important means to evaluate its service life. Since domestic oil has good oxidation stability and antioxidants are added, this project test is usually only carried out on new oil. However, for imported oil, especially oil without antioxidants, in addition to testing the new oil, this test should also be carried out after several years of operation so as to take appropriate maintenance measures and extend the service life.

Breakdown voltage: The breakdown voltage of transformer oil is a very important means of supervision to test the transformer oil's tolerance to the limit electrical stress. Under normal circumstances, it mainly depends on the degree of contamination, but when the oil has a high moisture content or contains impurity particles, it has a greater impact on the breakdown voltage.

Dielectric loss factor: The dielectric loss factor is very sensitive to judging the aging and contamination of transformer oil. New oil contains few polar impurities, so the dielectric loss factor is also very small, generally only 0.01% to 0.1%; but when the oil is aged due to oxidation or overheating, or when other impurities are mixed in, the polar impurities and charged colloidal substances generated gradually increase, and the dielectric loss factor will also increase accordingly. When the aging products of the oil are very small and cannot be detected by chemical methods, the dielectric loss factor can be clearly distinguished. Therefore, the determination of the dielectric loss factor is a common means of transformer oil inspection and supervision, and has special significance.

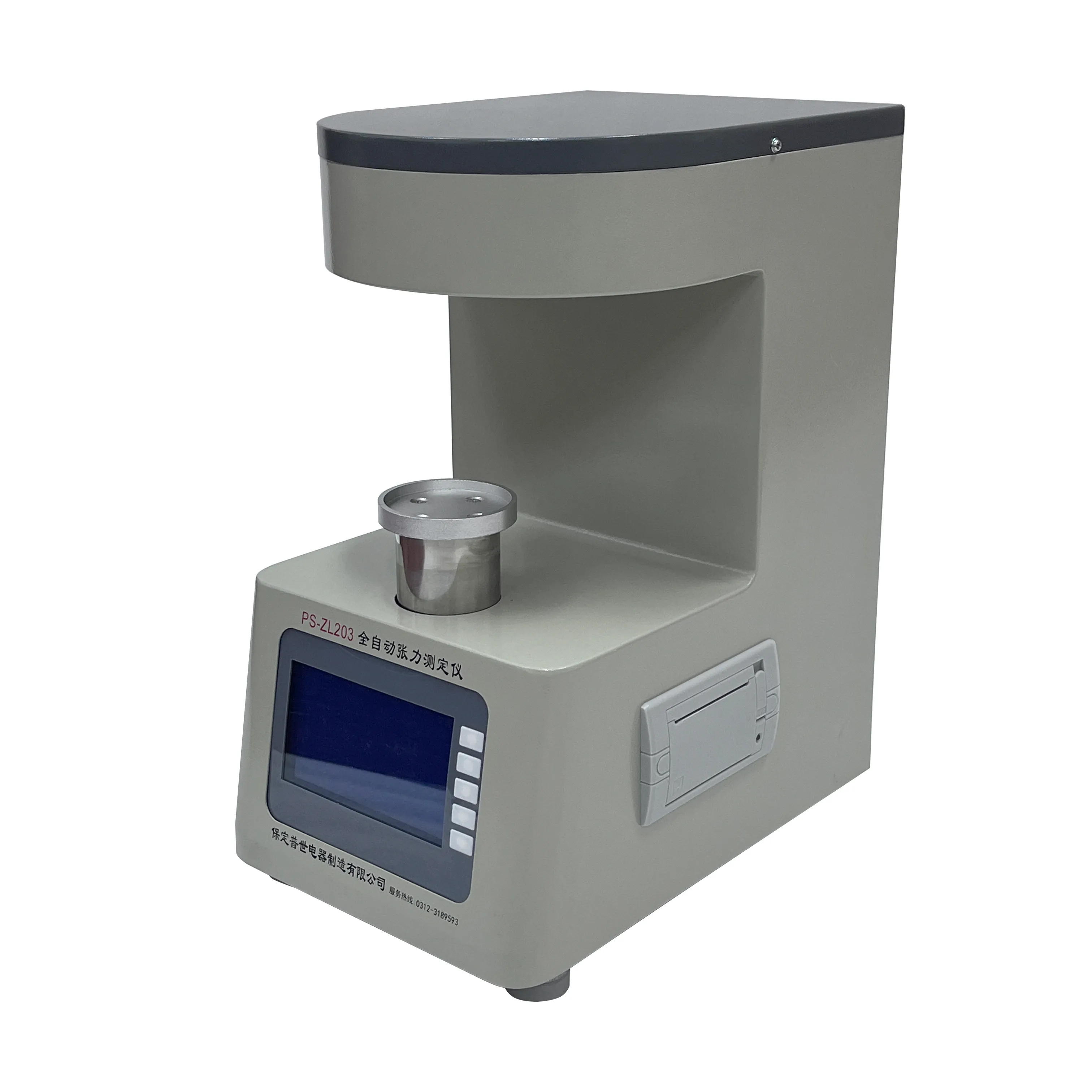

Interfacial tension: The determination of the interfacial tension between oil and water is an indirect and effective method to check whether the oil contains soluble polar impurities caused by aging. In the initial aging stage of the oil, the change of the interfacial tension is quite rapid, and in the middle of the aging, the change rate is reduced. The generation of sludge increases significantly, so this method can also make a reliable judgment on the trend of sludge generation.

Sludge: This method is to check the sludge sediment that can be precipitated from the oil when n-heptane is added when the running oil is still in a dissolved or colloidal state. Since the solubility of sludge in new oil and aged oil is different, when new oil infiltrates into aged oil, sludge will precipitate out. The deposition of sludge will affect the heat dissipation performance of the equipment, and also cause serious corrosion to solid insulating materials and metals, resulting in a decrease in insulation performance, which is more harmful. Therefore, when the oil is mixed at a ratio greater than 5%, a sludge precipitation test must be carried out.

Flash point: Flash point is an essential item for the supervision of operating oil. The reduction of flash point indicates that volatile combustible gases are generated in the oil; these combustible gases are often generated by local overheating of electrical equipment and thermal cracking of insulating oil at high temperature caused by arc discharge. The determination of flash point can timely detect equipment failures. At the same time, for transformer oil newly filled with equipment and after maintenance, the determination of flash point can also prevent or detect whether light distillate oil products are mixed in, thereby ensuring the safe operation of the equipment.

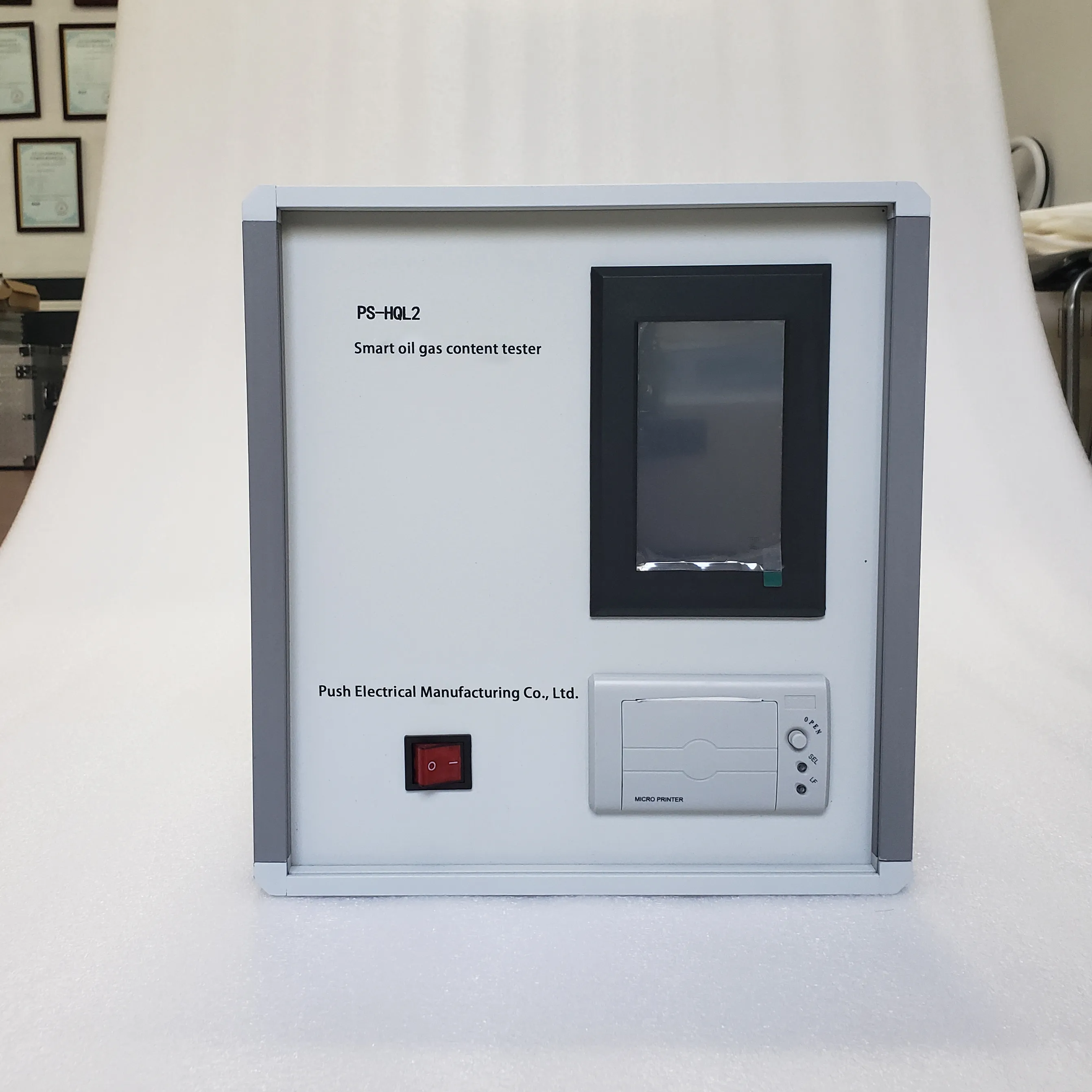

Gas component content in oil: Combustible gases in oil are generally generated by local overheating or discharge decomposition of equipment. If the cause of the generation of combustible gas is not identified and eliminated in time, it is very dangerous to the safe operation of the equipment. Therefore, the use of gas chromatography to determine the gas components in the oil is very effective in eliminating the latent faults of the transformer. This project is an essential test content in the operation supervision of transformer oil.

Water-soluble acid: Transformer oil is generally easy to generate low-molecular organic acids, such as formic acid and acetic acid, in the primary stage of oxidation. Because these acids have good water solubility, when the content of water-soluble acid in the oil increases (i.e., the pH value decreases), and the oil contains water, it will cause corrosion of solid insulating materials and metals, and reduce the insulation performance of electrical equipment and shorten the service life of the equipment.

Pollution point: According to my country's climatic conditions, transformer oil is divided into grades according to low-temperature performance. For example, the three grades of 10, 25, and 45 refer to the freezing points of -10, -25, and -45℃ respectively. Therefore, it is necessary to determine the freezing point for the acceptance of new oil and the mixing of different grades of oil.

Volume resistivity: The volume resistivity of transformer oil, like the dielectric loss factor, can judge the degree of aging and contamination of transformer oil. Water, contaminants and acidic products in the oil can all affect the reduction of resistivity.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024