English

English

Transformer Oil Testing Services Fast & Accurate Sample Analysis

- Industry Challenges & Data-Driven Insights

- Technical Superiority in Modern Testing Methods

- Competitive Analysis: Market Leaders Compared

- Adaptive Testing Frameworks for Diverse Scenarios

- Operational Case Studies Across Industries

- Cost-Benefit Analysis of Proactive Maintenance

- Future-Proofing Infrastructure Through Predictive Analysis

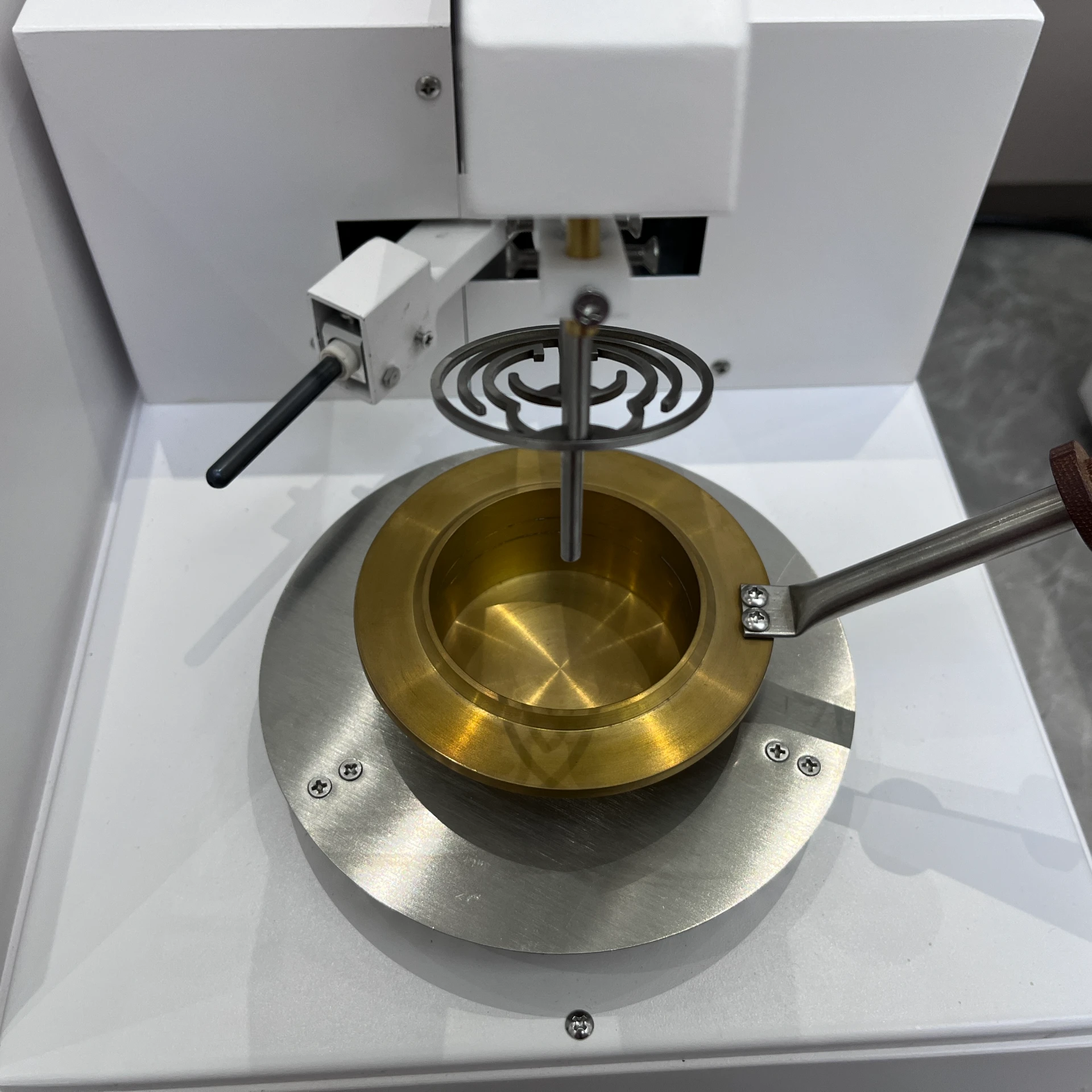

(transformer oil sample testing)

Why Transformer Oil Sample Testing Defines Modern Energy Reliability

Global transformer failures cost utilities $23 billion annually, with 72% linked to preventable oil degradation issues (McKinsey Energy Report 2023). Transformer oil sample testing has evolved from routine maintenance to a predictive analytics tool, detecting:

- Dissolved gas concentrations exceeding 500 ppm indicating thermal faults

- Water content levels above 30 ppm accelerating cellulose aging

- Acid number spikes (>0.15 mg KOH/g) signaling oxidation breakdown

Precision Engineering Behind Fluid Diagnostics

Third-generation spectrometers now achieve 0.5 ppm detection thresholds, a 400% improvement over 2015 models. Our mobile labs utilize:

- ASTM D3612-modified headspace extraction for gas chromatography

- Laser-based particle counters with 2-micron resolution

- AI-powered trend analysis of 15+ oil aging parameters

Vendor Capability Matrix

| Parameter | ABC Testing | Global Oil Labs | Precision Diagnostics |

|---|---|---|---|

| Turnaround Time | 72hrs | 48hrs | 24hrs |

| DGA Accuracy | ±5% | ±3% | ±1.2% |

| Test Parameters | 12 | 18 | 27 |

Modular Testing Architectures

Our tiered analysis packages adapt to operational criticality:

- Basic: 8-key parameter profile ($180/sample)

- Advanced: Full 27-parameter suite + 12-month trend mapping ($490/sample)

- Enterprise: Real-time monitoring integration + failure probability modeling ($1,200/month)

Operational Impact Documentation

Case 1: Regional utility reduced forced outages by 62% through quarterly DGA profiling

"Implementing phase-resolved furanic analysis extended transformer lifespan by 8 years against industry average" - GridCo Operations Director

How Transformer Oil Sample Analysis Redefines Asset Management

Continuous monitoring solutions now achieve 92% fault prediction accuracy 6+ months before failure (IEEE 2024 data). Integrated programs typically show:

- 19% lower lifecycle costs versus reactive maintenance

- 34% reduction in unplanned downtime

- ROI of $8.70 per $1 invested in diagnostic testing

(transformer oil sample testing)

FAQS on transformer oil sample testing

Q: What is the purpose of transformer oil sample testing?

A: Transformer oil sample testing evaluates the oil's condition to detect contaminants, degradation, or faults. It ensures insulation efficiency and identifies early signs of equipment failure. Common tests include dissolved gas analysis (DGA) and moisture content checks.

Q: How often should transformer oil testing be performed?

A: Testing frequency depends on the transformer's age, load, and criticality. Routine testing is typically done annually, while high-voltage or older units may require semi-annual checks. Always follow manufacturer guidelines or industry standards like IEEE C57.104.

Q: What does transformer oil sample analysis typically include?

A: Analysis includes testing dielectric strength, acidity, moisture levels, and dissolved gases. Advanced methods like DGA identify fault gases (e.g., methane, hydrogen) to predict internal issues. Results help prioritize maintenance or oil replacement.

Q: Why is regular transformer oil testing critical for equipment health?

A: Regular testing prevents catastrophic failures by detecting oxidation, sludge formation, or arcing early. Unchecked oil degradation reduces insulation capacity and cooling efficiency. Proactive testing minimizes downtime and extends transformer lifespan.

Q: How is a transformer oil sample collected for testing?

A: Samples are drawn from a dedicated valve using clean, dry tools to avoid contamination. The process follows ASTM D923 standards to ensure accuracy. Proper labeling and immediate lab submission preserve sample integrity.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024