English

English

transformer paper insulation testing

Transformer paper insulation is a critical component in ensuring the reliability and performance of transformers used in electrical systems. The insulation serves to separate the windings and prevent short circuits, enabling the transformer to operate under high voltages without failure. Over time, the insulation material can deteriorate due to factors such as heat, moisture, and electrical stresses, which can compromise the overall integrity of the transformer. Consequently, regular testing of transformer paper insulation is essential to assess its condition and performance.

One of the primary methods for testing transformer paper insulation is through dielectric testing. This involves applying a voltage to the insulation material and measuring its response. The key parameters evaluated during this testing include insulation resistance, power factor, and dielectric strength. Insulation resistance is measured with an ohmmeter and is indicative of the material’s ability to resist electrical current. A high insulation resistance value suggests good insulation quality, while a low value may indicate moisture ingress or degradation.

Power factor testing provides insights into the energy lost as heat within the insulation. This test involves applying an AC voltage and measuring the phase difference between the voltage and current. A higher power factor indicates increased losses in the insulation, often due to aging or contamination. Monitoring the power factor over time can help identify trends that may indicate the need for maintenance or replacement.

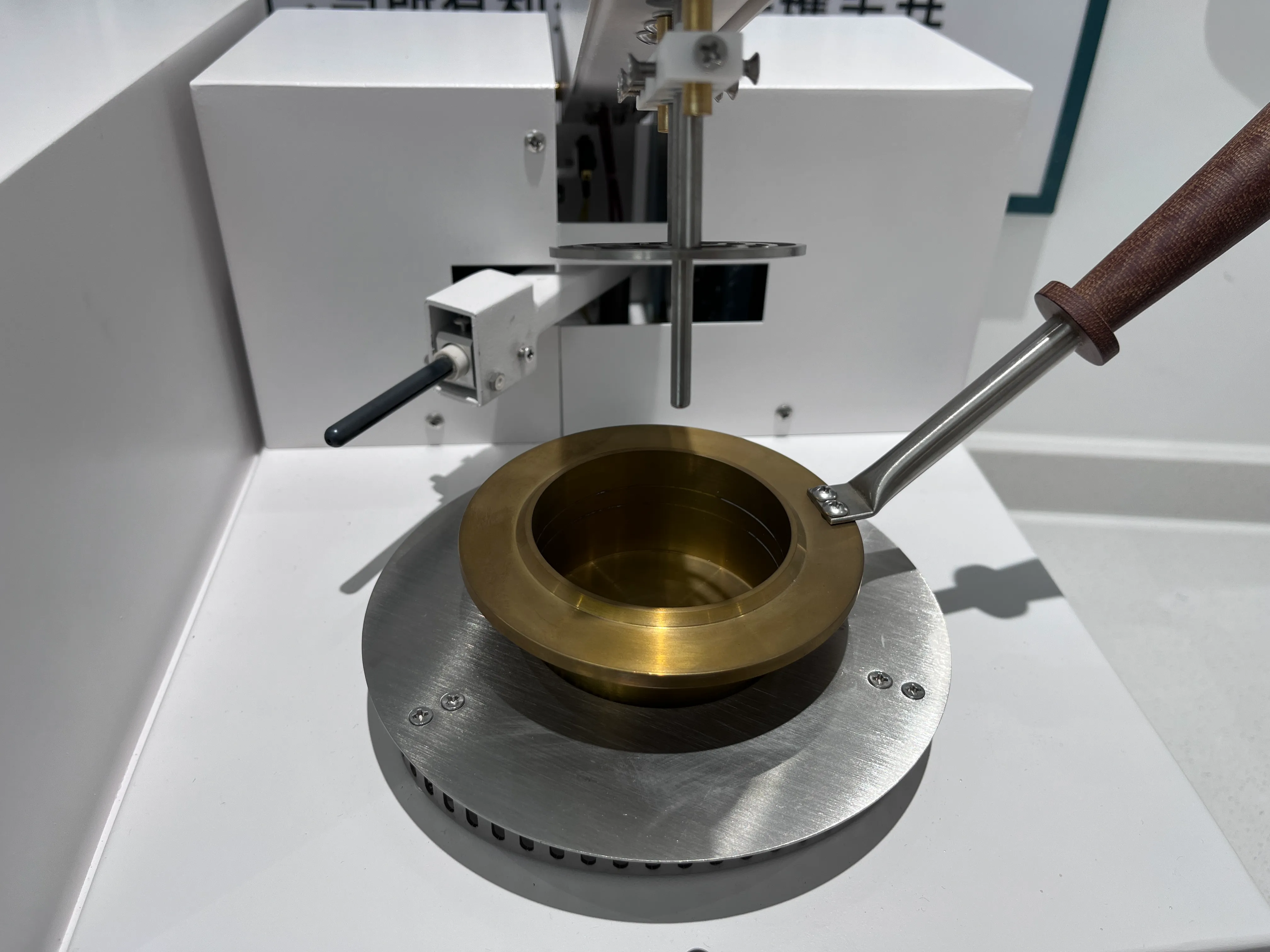

Dielectric strength testing evaluates the maximum voltage that the insulation material can withstand before breakdown occurs. This is a critical measurement as it provides a direct indication of the insulation's ability to protect against transient voltage spikes. By using a gradually increasing voltage until the insulation fails, engineers can determine its dielectric breakdown point, thus assessing its suitability for continued service.

transformer paper insulation testing

In addition to traditional testing methods, advanced techniques such as partial discharge measurements and thermography are gaining popularity. Partial discharge testing detects small electrical discharges that occur within the insulation at high voltages. These discharges can indicate weaknesses or defects in the insulation material. Thermography involves capturing thermal images of the transformer, identifying hot spots that could signify insulation failure or excessive heating.

Regular testing of transformer paper insulation not only extends the lifespan of the transformer but also enhances safety and reliability in electrical systems. Utilities and industrial facilities must implement rigorous testing protocols as part of their maintenance strategies to prevent unexpected failures, which can lead to costly downtime and equipment damage. As technology evolves, integrating smart diagnostic tools into transformer maintenance practices will enable proactive monitoring and more accurate assessments of insulation health over time.

In summary, transformer paper insulation testing is a vital aspect of transformer maintenance. By employing various testing methods, electrical engineers can ensure that insulation remains effective and reliable, safeguarding the operation of transformers and the overall integrity of power systems. Through continuous monitoring and assessment, organizations can effectively manage their assets and prevent potential failures caused by insulation degradation.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024