English

English

Evaluating and Verifying Transformer Performance and Safety Standards

Transformer Inspection and Testing Ensuring Reliability and Safety

Transformers play a pivotal role in electrical power systems by facilitating the transmission and distribution of electricity. Therefore, ensuring their reliability and safety through regular inspection and testing is paramount. This article sheds light on the significance of transformer inspection and testing, the methodologies employed, and the benefits they provide to operators and utility companies.

Importance of Transformer Inspection and Testing

The primary purpose of transformer inspection and testing is to identify potential issues before they lead to catastrophic failures. Regular inspections help detect anomalies such as insulation deterioration, overheating, and equipment degradation. Additionally, they ensure compliance with regulatory standards, thus safeguarding both the infrastructure and the public. Failure to properly inspect and maintain transformers can lead to unexpected outages, costly repairs, or even environmental hazards due to oil leaks.

Types of Inspections

Transformer inspections generally fall into two categories visual inspections and diagnostic testing

.1. Visual Inspections This preliminary step involves checking the physical condition of the transformer and its components. Inspectors look for signs of leaks, corrosion, wear, and other visible issues. The check also extends to the transformer’s surroundings to assess whether any external factors could affect its operation.

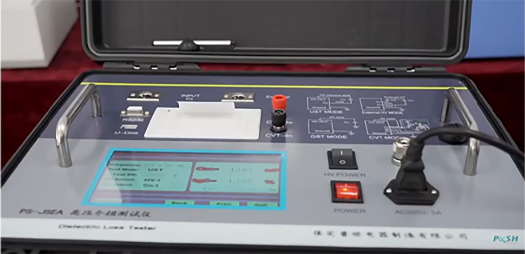

2. Diagnostic Testing This phase employs various techniques to evaluate the operational integrity of the transformer. Common diagnostic tests include

transformer inspection and testing

- Insulation Resistance Testing This test assesses the quality of the insulation material. High levels of moisture or impurities in the insulation can lead to failures, and this test can help identify such issues. - Power Factor Testing This helps determine the condition of insulation within the transformer. A low power factor indicates deterioration of the insulation, signaling that further investigation or maintenance might be necessary. - Sweep Frequency Response Analysis (SFRA) This technique evaluates the mechanical integrity of the transformer windings. Any significant deviation in response between tests can suggest potential mechanical issues.

- Dissolved Gas Analysis (DGA) This critical test analyzes gases dissolved in the transformer oil. The presence of specific gases can indicate faults such as overheating, arcing, or insulation failure.

Benefits of Regular Inspection and Testing

Conducting regular and thorough inspections and tests offers numerous benefits. Primarily, it enhances the reliability of the power supply, reducing the likelihood of failures that can lead to outages. Additionally, it extends the service life of transformers, allowing utility companies to optimize their investments.

Economic advantages are also significant. By proactively identifying and addressing potential issues, operators can avoid costly emergency repairs and the associated downtime. Furthermore, maintaining compliance with regulations helps avoid penalties and enhances safety for personnel and the surrounding environment.

Conclusion

Transformer inspection and testing are integral components of effective electrical infrastructure management. By adopting systematic inspection regimes and advanced diagnostic techniques, companies can significantly enhance the reliability and safety of their transformers. As electricity demand continues to rise, the importance of ensuring the optimal operation of transformers cannot be overstated. Investing in regular inspections not only protects assets but also contributes to a stable and efficient electrical grid, ultimately benefiting consumers and industries alike.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024