TEL:

+86-0312-3189593

English

English

Telephone:0312-3189593

Email:sales@oil-tester.com

1 月 . 21, 2025 01:55

Back to list

transformer oil bdv tester

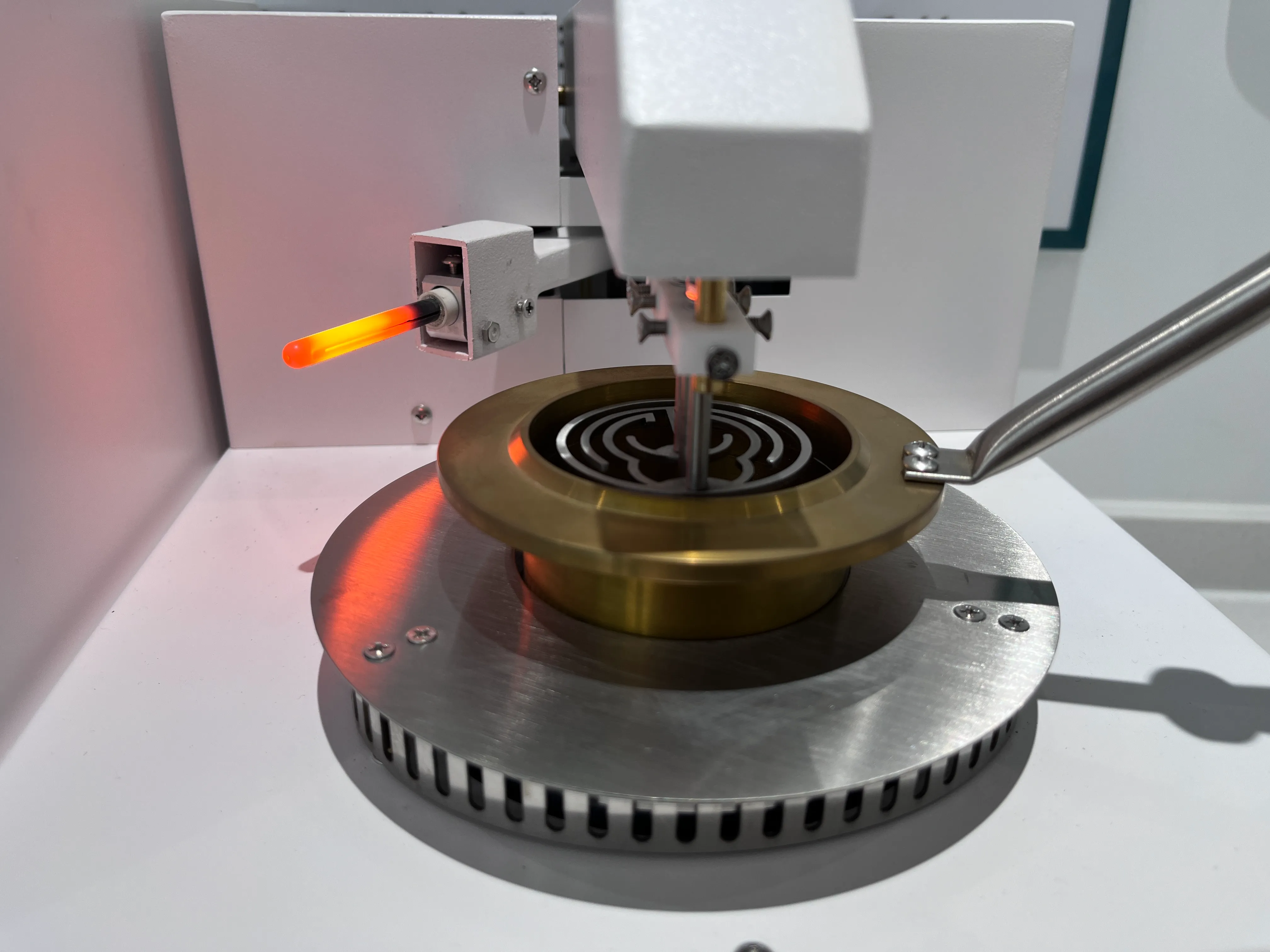

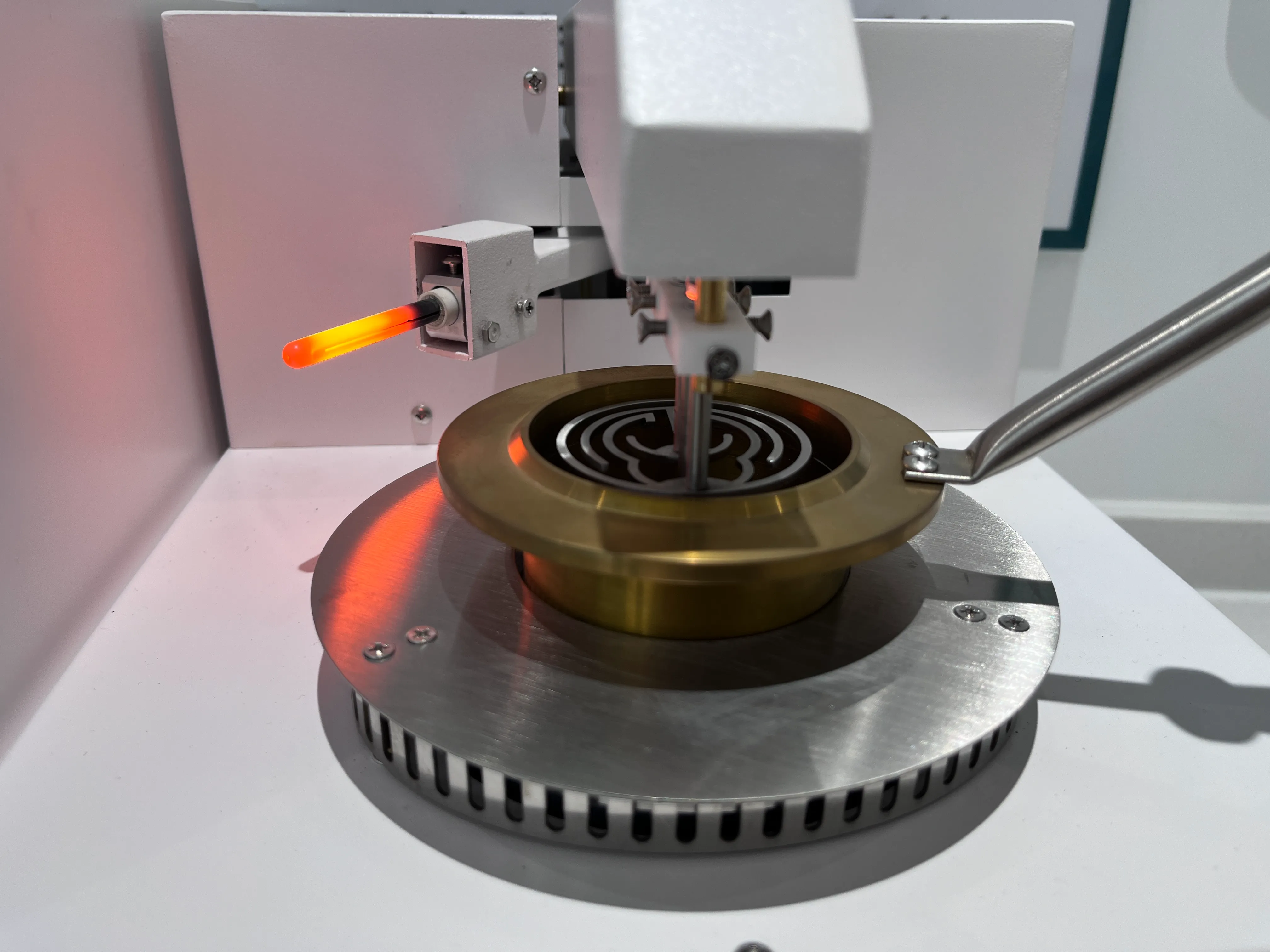

Ensuring the safety and efficiency of transformers in power systems is a complex task that demands specialized tools, one of which is the transformer oil BDV (Breakdown Voltage) tester. This essential device is used to gauge the insulating strength of transformer oil, crucial for uninterrupted power delivery. When looking for a transformer oil BDV tester, comprehending its functionality, advantages, and selection criteria bolsters not only operational efficiency but also contributes to the overarching robustness of electrical systems.

Furthermore, practitioners in the field often report that investing in a reliable BDV tester equates to long-term economic benefits. A precise tester reduces the frequency of transformer failures by ensuring timely maintenance interventions. This predictive maintenance capability saves substantial costs associated with unplanned downtime and extends the service life of valuable infrastructure assets. Additionally, models featuring a user-friendly interface, with detailed readouts and intuitive navigation, augment user experience, reducing the learning curve involved. These designs facilitate quick adoption and utilization, enhancing productivity. Enhanced safety features, such as enclosed testing chambers with sturdy dielectric materials, are instrumental in protecting users from potential hazards during testing procedures. It's critical to prioritize testers that allow for easy portability without compromising on performance. Portable BDV testers traditionally benefit field engineers who operate across diverse locations, ensuring that test operations remain flexible and reliable regardless of geographical constraints. The seamless integration of modern testers with digital management systems has redefined testing paradigms. High-end models offer wireless data transfer capabilities, enabling the real-time sharing of test results. This feature amplifies operational coordination and supports faster data-driven decision-making processes, integral in high-paced industrial environments. In a highly connected technological era, transformer oil BDV testers have proven indispensable in safeguarding power system efficiency. By selecting the right equipment, companies not only enhance operational reliability but also fortify their standing in a competitive landscape influenced by evolving energy demands. Therefore, the judicious combination of experience-based selections and advanced technological features defines excellence in transformer oil testing—forming the backbone of sustainable and reliable electrical infrastructure.

Furthermore, practitioners in the field often report that investing in a reliable BDV tester equates to long-term economic benefits. A precise tester reduces the frequency of transformer failures by ensuring timely maintenance interventions. This predictive maintenance capability saves substantial costs associated with unplanned downtime and extends the service life of valuable infrastructure assets. Additionally, models featuring a user-friendly interface, with detailed readouts and intuitive navigation, augment user experience, reducing the learning curve involved. These designs facilitate quick adoption and utilization, enhancing productivity. Enhanced safety features, such as enclosed testing chambers with sturdy dielectric materials, are instrumental in protecting users from potential hazards during testing procedures. It's critical to prioritize testers that allow for easy portability without compromising on performance. Portable BDV testers traditionally benefit field engineers who operate across diverse locations, ensuring that test operations remain flexible and reliable regardless of geographical constraints. The seamless integration of modern testers with digital management systems has redefined testing paradigms. High-end models offer wireless data transfer capabilities, enabling the real-time sharing of test results. This feature amplifies operational coordination and supports faster data-driven decision-making processes, integral in high-paced industrial environments. In a highly connected technological era, transformer oil BDV testers have proven indispensable in safeguarding power system efficiency. By selecting the right equipment, companies not only enhance operational reliability but also fortify their standing in a competitive landscape influenced by evolving energy demands. Therefore, the judicious combination of experience-based selections and advanced technological features defines excellence in transformer oil testing—forming the backbone of sustainable and reliable electrical infrastructure.

Previous:

Latest news

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024