English

English

Testing the Dielectric Strength of Transformer Oil in Electrical Applications

The Importance of Dielectric Strength Testing for Transformer Oil

Transformer oil plays a crucial role in the efficient and safe operation of transformers, serving both as an insulator and a coolant. One of the key properties of transformer oil is its dielectric strength, which refers to the maximum electric field the oil can withstand without experiencing breakdown, resulting in conductivity. Understanding and testing the dielectric strength of transformer oil is vital for ensuring the reliability and longevity of transformers in various applications.

Dielectric strength is typically measured in kilovolts per millimeter (kV/mm) and indicates the oil's ability to insulate electrical components and prevent unwanted electrical discharges. When the dielectric strength of transformer oil falls below a certain threshold, it can lead to failures such as arcing, short circuits, or even catastrophic transformer failures. Hence, regular testing is essential for maintaining the safety and functionality of transformer systems.

Testing Procedures

Conducting a dielectric strength test involves several steps to ensure accuracy and reliability. The most common method used is the ASTM D1816 standardized test, which involves placing a sample of transformer oil in a test cell that features two electrodes. The test cell is typically designed with a controlled gap between the electrodes set at a specified distance to prevent flashover from occurring due to other factors.

During the test, an AC voltage is incrementally applied to the electrodes while monitoring the oil's response. The voltage is increased until breakdown occurs, at which point the dielectric strength can be recorded. This procedure not only provides insights into the current condition of the oil but also helps identify any impurities or degradation that may compromise the insulation properties over time.

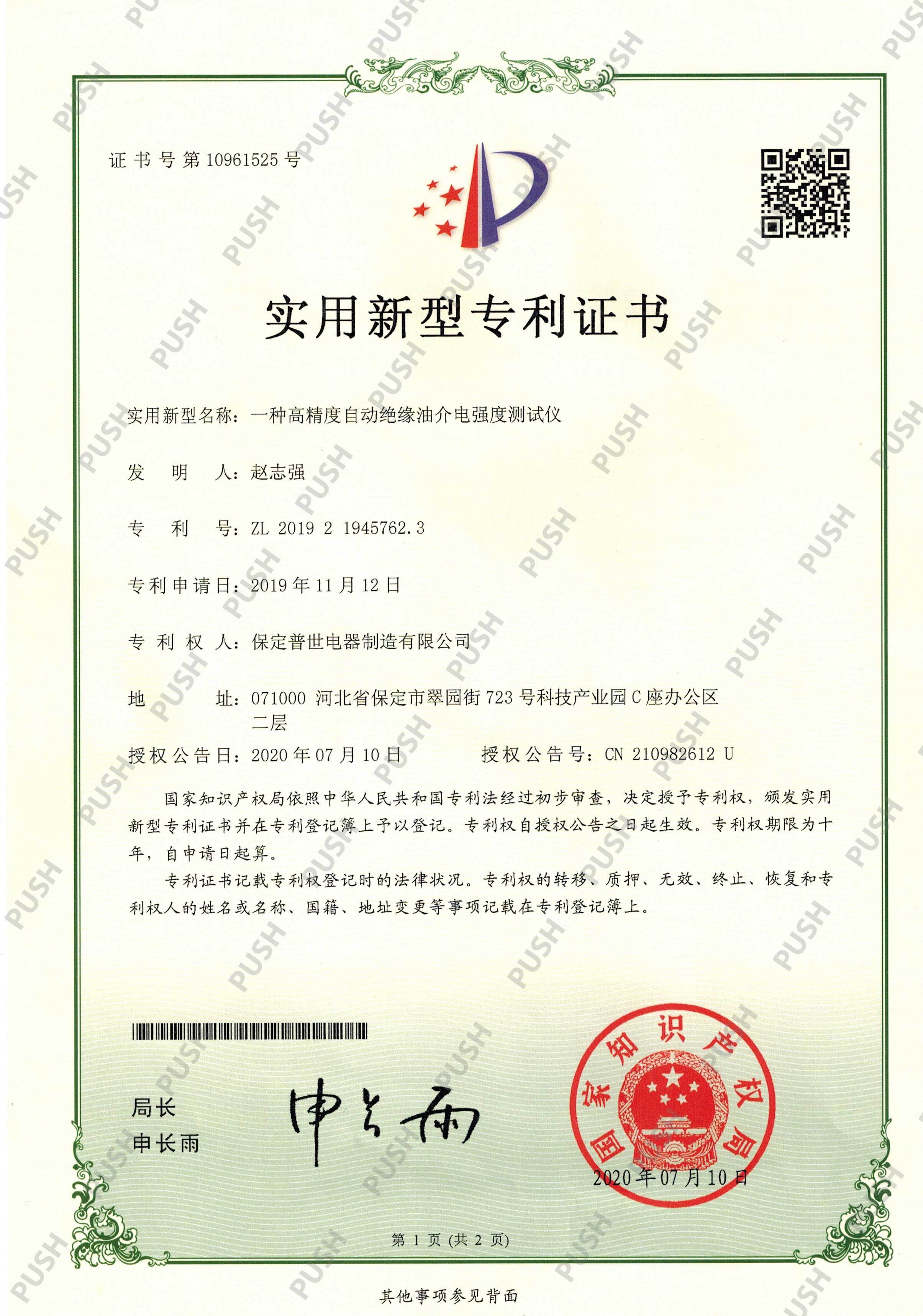

transformer oil dielectric strength test

Factors Affecting Dielectric Strength

Several factors influence the dielectric strength of transformer oil, including its chemical composition, temperature, and the presence of contaminants such as moisture, dirt, or chemicals. Moisture, for instance, is a notorious enemy of transformer oil, significantly reducing its dielectric properties. The presence of particulate matter or dissolved gases can also adversely affect performance.

Regular monitoring and maintenance practices, including filtration and dehydration, can help mitigate these issues, ensuring that the oil maintains optimal dielectric strength. Furthermore, advancements in oil processing techniques are enabling the production of transformer oils with superior dielectric properties, enhancing transformer efficiency and safety.

Conclusion

In conclusion, the dielectric strength test for transformer oil is an essential aspect of transformer maintenance and operation. By understanding the significance of this testing and the factors that affect dielectric strength, electrical engineers and maintenance teams can take proactive measures to ensure the reliability and safety of transformer systems. As the demand for electrical power continues to grow, investing in quality transformer oil and regular dielectric testing will ultimately support a stable and sustainable energy future. Regular assessments of dielectric strength not only safeguard against failure but also enhance the overall performance of electrical systems, proving that prevention is indeed better than cure in the world of electrical engineering.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024