English

English

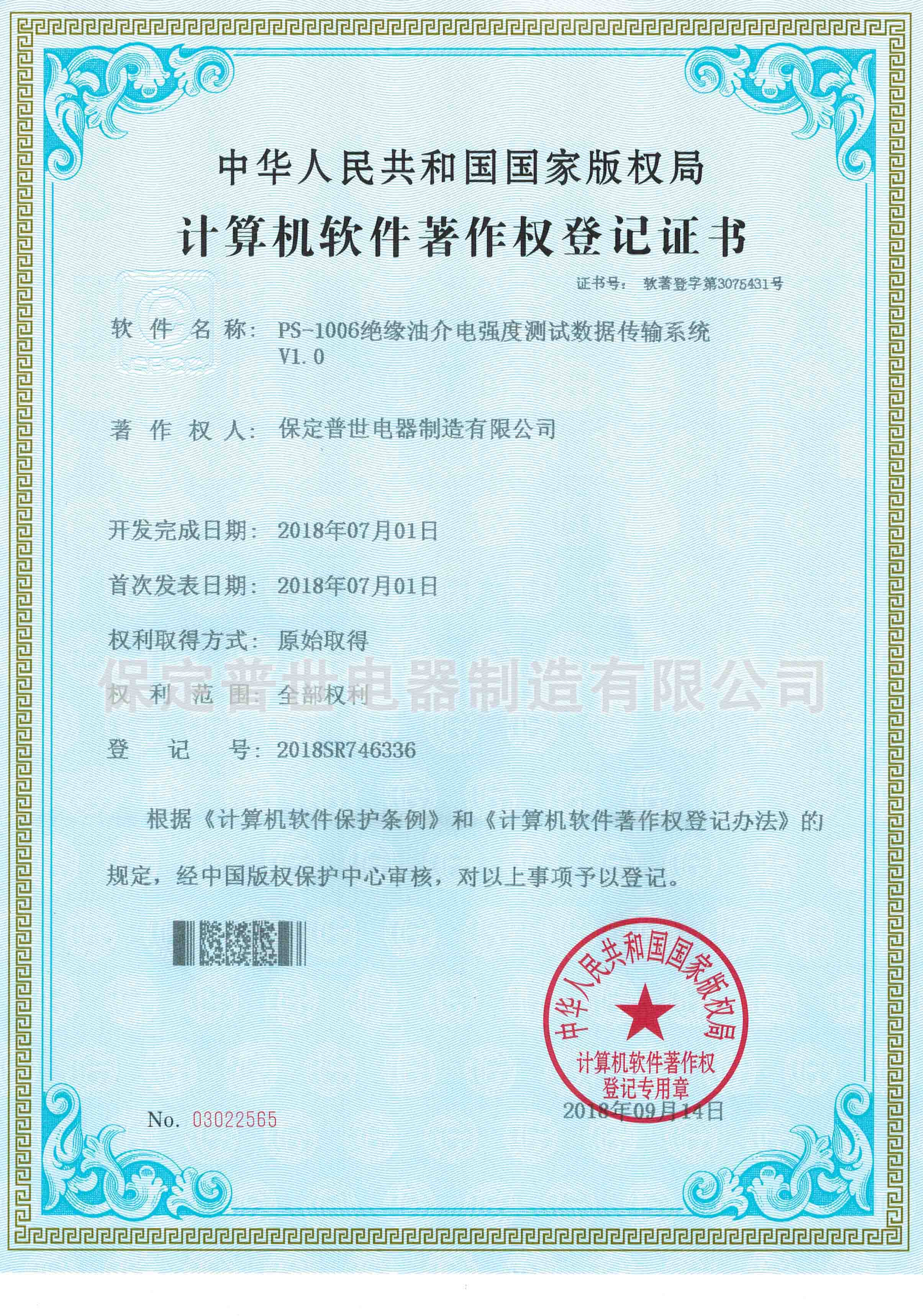

transformer oil dielectric strength test

Transformer Oil Dielectric Strength Test Ensuring Electrical Safety and Efficiency

Transformer oil, often referred to as insulating oil, plays a critical role in the operation of transformers and other electrical equipment. One of the key properties of transformer oil is its dielectric strength, which refers to its ability to insulate and prevent electrical breakdown. Measuring dielectric strength is crucial because it can significantly affect the performance and longevity of electrical systems.

The dielectric strength of transformer oil is determined through a standardized testing process, usually involving a transformer oil dielectric strength test. This test involves applying a steadily increasing voltage to a specimen of oil until breakdown occurs. The voltage at which the oil fails to insulate is recorded to determine its dielectric strength, typically measured in kilovolts per millimeter (kV/mm).

The importance of the dielectric strength test cannot be overstated. A high dielectric strength indicates that the transformer oil is effective in preventing electrical discharges, which can lead to equipment failure, fire hazards, and costly downtime. Conversely, a low dielectric strength suggests that the oil may be contaminated or degraded, necessitating maintenance or replacement.

transformer oil dielectric strength test

Several factors can influence the dielectric strength of transformer oil. Contaminants such as moisture, particulate matter, and acids can significantly reduce its insulating properties. Regular testing ensures that any degradation can be identified early, allowing for corrective actions to be taken. Additionally, the presence of air bubbles within the oil can also compromise dielectric strength, making the testing process essential for maintaining optimal operating conditions.

Typically, transformer oil should have a dielectric strength above specific thresholds, which may vary depending on the equipment in use. For instance, a dielectric strength below 30 kV/mm might be concerning, prompting further investigation and remedial action.

The testing process itself is relatively straightforward. Samples of the transformer oil are taken and placed in a test cell equipped with electrodes. As voltage is gradually applied, observers monitor for signs of breakdown. This testing can be performed in the field or in a laboratory setting, depending on the preferences and regulations of the operating entity.

In conclusion, the transformer oil dielectric strength test is a vital procedure in the maintenance of electrical systems. By ensuring the oil maintains a high dielectric strength, electrical utilities can prevent failures, protect their equipment, and sustain operational integrity. Regular monitoring and testing not only enhance safety but also contribute to the overall efficiency and reliability of electrical infrastructures.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024