TEL:

+86-0312-3189593

English

English

Telephone:0312-3189593

Email:sales@oil-tester.com

1 月 . 15, 2025 09:15

Back to list

PS-ZRD03 Lubricating Grease Cone Lubricity Oil Penetration Tester Penetrometer Astdm 217

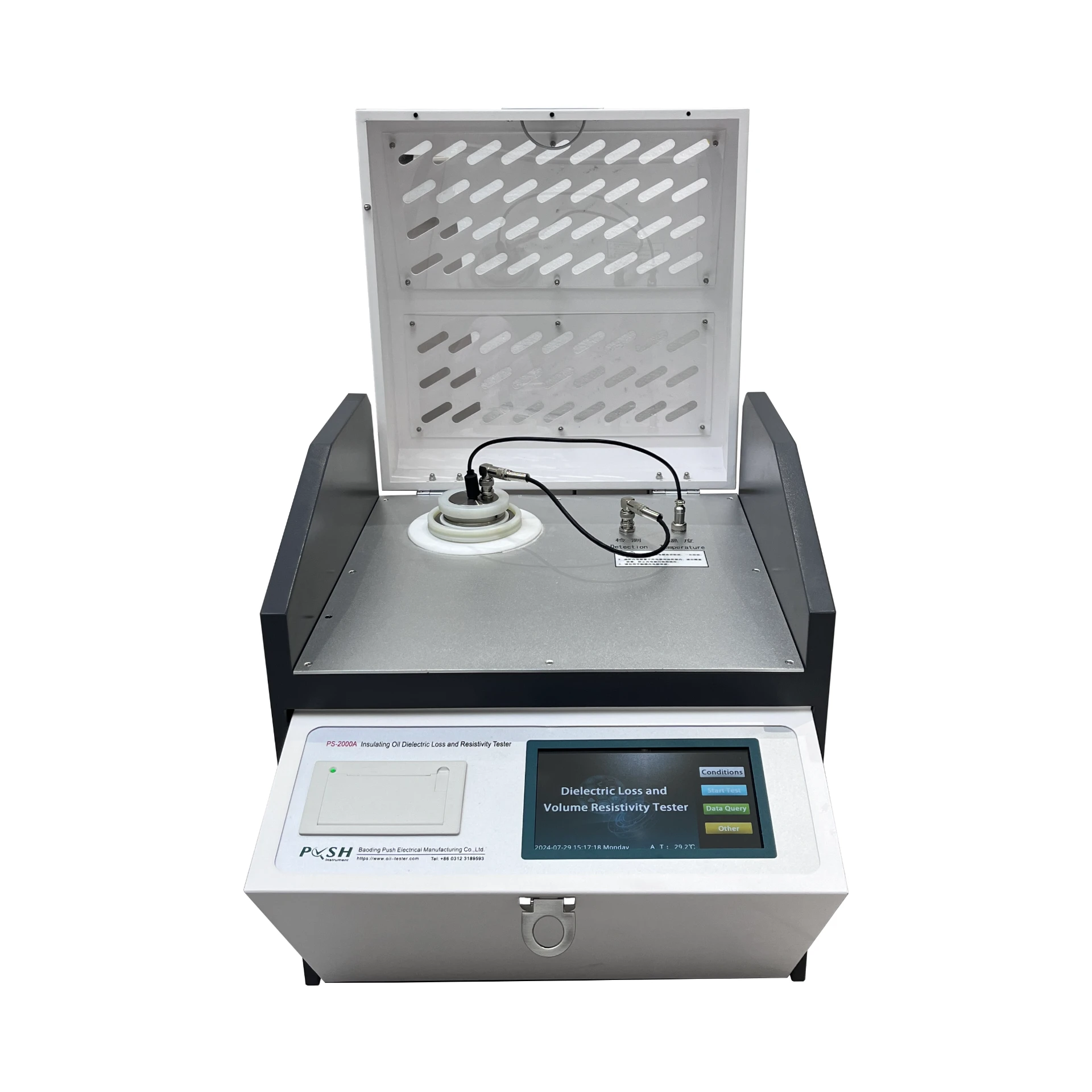

Transformer oil testing is an essential process for maintaining the health and efficiency of electrical transformers. The equipment used in this testing process plays a crucial role in diagnosing potential issues that could lead to transformer failure. Ensuring that transformer oil is in optimal condition is not only about preventing costly downtime but also about enhancing safety and prolonging the lifespan of transformers. Here's an in-depth look at transformer oil testing equipment, designed to meet the Experience, Expertise, Authoritativeness, and Trustworthiness criteria.

For those seeking to purchase or upgrade their transformer oil testing equipment, it's essential to consider innovations that improve user experience and testing accuracy. Modern equipment often features digital interfaces, providing users with real-time data and insights. The incorporation of IoT (Internet of Things) technologies in some testing equipment allows for remote monitoring and diagnostics, further enhancing the reliability and convenience of the testing process. Expertise in choosing the right transformer oil testing equipment also involves considering the brand's reputation and the support services they offer. It’s beneficial to select equipment from authoritative brands known for their rigorous quality standards and customer support, ensuring that the instruments are reliable and any technical issues can be promptly addressed. Trustworthiness in transformer oil testing does not only lie in the precision of the equipment but also in the calibration and maintenance practices. Regular calibration of testing tools is necessary for ensuring that results remain accurate over time. Engaging in best practices for maintenance and calibration protects the integrity of the testing process, fostering confidence in the results. In conclusion, investing in reliable and advanced transformer oil testing equipment is indispensable for maintaining the performance and safety of transformers. By understanding the distinct functions of various testing tools and adhering to high standards of expertise and trustworthiness, organizations can effectively monitor and manage the health of their transformers, thereby safeguarding their operations and investments.

For those seeking to purchase or upgrade their transformer oil testing equipment, it's essential to consider innovations that improve user experience and testing accuracy. Modern equipment often features digital interfaces, providing users with real-time data and insights. The incorporation of IoT (Internet of Things) technologies in some testing equipment allows for remote monitoring and diagnostics, further enhancing the reliability and convenience of the testing process. Expertise in choosing the right transformer oil testing equipment also involves considering the brand's reputation and the support services they offer. It’s beneficial to select equipment from authoritative brands known for their rigorous quality standards and customer support, ensuring that the instruments are reliable and any technical issues can be promptly addressed. Trustworthiness in transformer oil testing does not only lie in the precision of the equipment but also in the calibration and maintenance practices. Regular calibration of testing tools is necessary for ensuring that results remain accurate over time. Engaging in best practices for maintenance and calibration protects the integrity of the testing process, fostering confidence in the results. In conclusion, investing in reliable and advanced transformer oil testing equipment is indispensable for maintaining the performance and safety of transformers. By understanding the distinct functions of various testing tools and adhering to high standards of expertise and trustworthiness, organizations can effectively monitor and manage the health of their transformers, thereby safeguarding their operations and investments.

Previous:

Latest news

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024