English

English

Testing Equipment for Transformer Oil Analysis and Quality Assessment

Understanding Transformer Oil Testing Equipment Ensuring Reliability and Safety in Electrical Systems

Transformer oil plays a crucial role in the operation and longevity of electrical transformers, serving as both insulation and a coolant. As transformers are vital components in electrical systems—converting voltage levels and facilitating the transmission of electricity—it's essential to monitor and maintain the condition of the transformer oil. This is where transformer oil testing equipment comes into play, offering insights into the health of the oil and, consequently, the transformer itself.

The Importance of Transformer Oil Testing

Transformers operate under high voltages, and any failure in their insulation or cooling capabilities can lead to catastrophic results, including overheating and permanent damage. Over time, transformer oil can degrade due to thermal stresses, exposure to moisture, and chemical reactions that produce harmful by-products. Testing the oil helps identify these potential issues before they escalate into serious problems. Regular oil testing not only extends the life of the transformer but also ensures the reliability of the electrical system in which it operates.

Key Tests Conducted on Transformer Oil

Transformer oil testing involves a range of analytical procedures designed to evaluate different properties of the oil. Some of the most common tests include

1. Dissolved Gas Analysis (DGA) This test identifies and quantifies gases that dissolve in the transformer oil. The presence of certain gases, like hydrogen, methane, or ethylene, can indicate various types of faults within the transformer. Analyzing the gas composition helps predict potential failures.

2. Moisture Content The moisture level in transformer oil is critical. Excess water can significantly lower the insulating properties of the oil, making it more susceptible to electrical breakdown. Karl Fischer titration is a widely used method to determine the moisture content accurately.

3. Dielectric Strength This test assesses the oil’s ability to withstand electrical stress without breaking down. A high dielectric strength indicates that the oil retains its insulating properties, while a decline could signal contamination or degradation.

4. Furan Analysis Furan compounds are by-products of paper insulation degradation. By measuring the concentration of these compounds in the oil, technicians can evaluate the condition of the transformer’s paper insulation, enabling proactive maintenance.

5. Acidity and Neutralization Number The acidity test measures the oil’s pH level, which can indicate oxidation and degradation. A high acidity can affect the oil's performance and lead to damaging chemical reactions within the transformer.

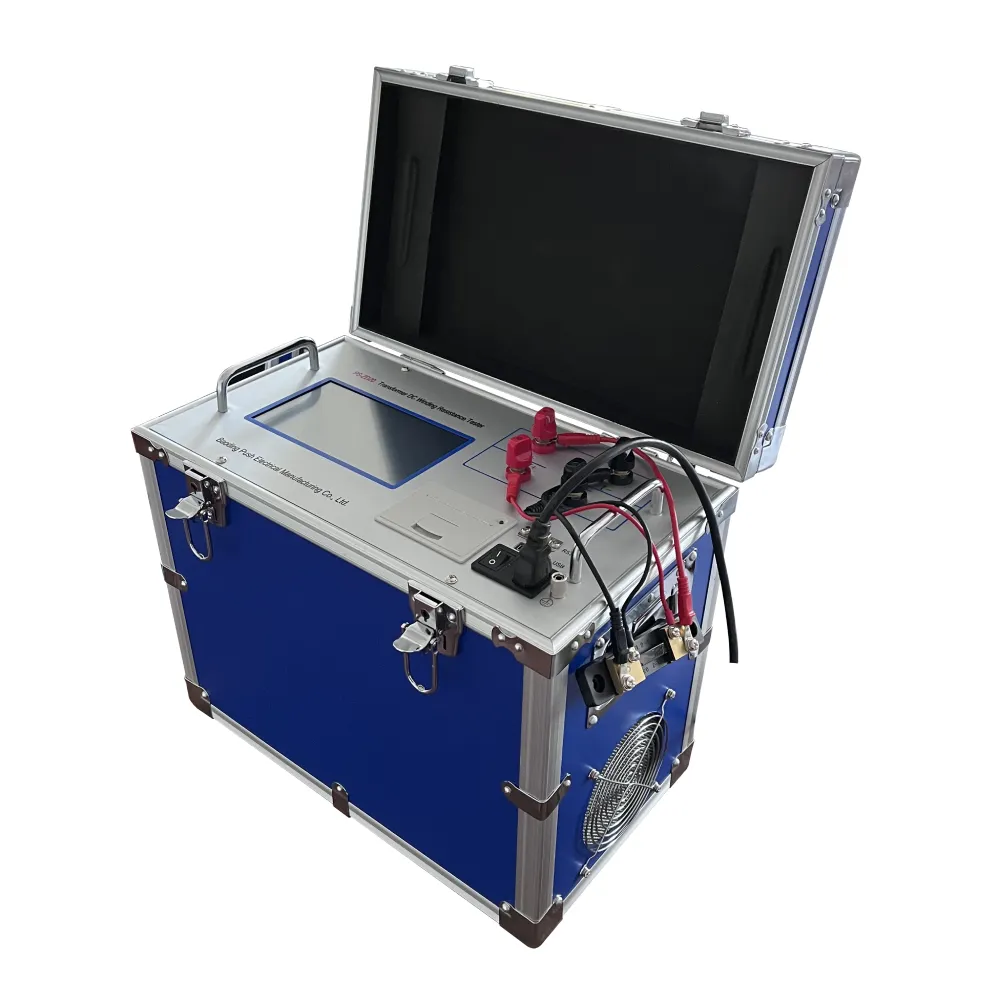

transformer oil testing equipment

6. Flash Point This test determines the temperature at which the oil vapors ignite. A lower flash point can indicate contamination, which can be dangerous in the operational environment of high-voltage transformers.

Equipment Used in Transformer Oil Testing

Transformer oil testing requires specialized equipment to ensure accurate and reliable results. The following instruments are commonly used

- Gas Chromatographs For conducting Dissolved Gas Analysis, these instruments separate and quantify the gases present in the oil.

- Moisture Analyzers Utilizing Karl Fischer titration technology, these devices provide precise measurements of moisture content.

- Dielectric Strength Testers These machines apply voltage to a sample of transformer oil to determine its insulating strength.

- Furan Test Kits These kits enable rapid testing for furan compounds, offering insights into the condition of insulation materials.

- Acidity Testers Portable or lab-based equipment that helps in evaluating the acidity of transformer oil.

Conclusion

Transformer oil testing equipment is essential for maintaining the health and efficiency of electrical transformers. By conducting regular tests on transformer oil properties, technicians can detect issues early, mitigate risks, and ensure the reliability and safety of electrical systems. As technology advances, testing equipment continues to evolve, incorporating sophisticated methodologies that enhance the precision of oil analysis. Ultimately, investing in transformer oil testing not only safeguards infrastructure but also contributes to the overall efficiency of the power supply network, benefiting consumers and industry alike.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024