TEL:

+86-0312-3189593

English

English

Telephone:0312-3189593

Email:sales@oil-tester.com

2 月 . 15, 2025 20:27

Back to list

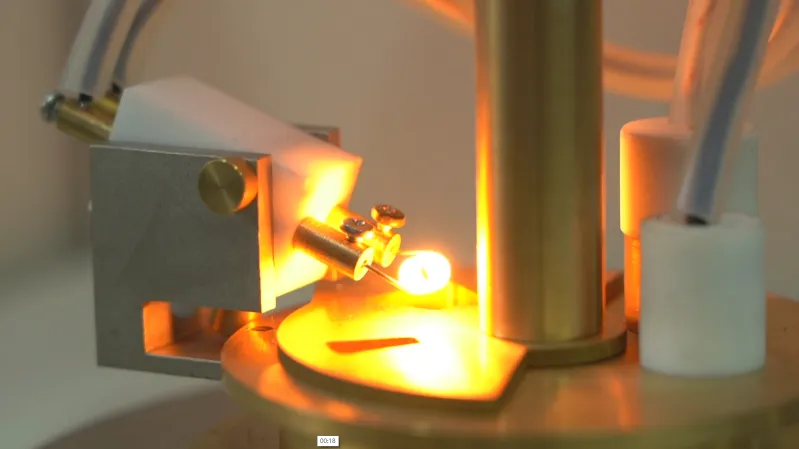

transformer oil testing types

Transformer oil testing is a critical procedure that ensures the longevity and efficiency of transformers, playing an indispensable role in the broader domain of electrical maintenance. Understanding the different types of transformer oil testing can help businesses maintain equipment health, minimize downtime, and enhance operational efficiency.

Interfacial Tension (IFT) Testing measures the oil's ability to maintain a barrier against moisture penetration. Low IFT values signify contamination or oxidation, which prompts further investigative measures or oil purification processes. Monitoring IFT offers an additional layer to ensuring the robustness of transformer oil insulation. By leveraging the outcomes from these transformer oil tests, companies can ensure a proactive maintenance strategy that significantly extends equipment life, reduces the risk of downtime, and enhances safety standards. Consistent monitoring and testing align closely with industry-established benchmarks and best practices, safeguarding the substantial investments placed in electrical infrastructure. In the context of emerging technological advancements, transformer oil testing also embraces digitalization through automated testing solutions that ensure greater precision and reduced human error. AI-powered diagnostic tools can continuously interpret data derived from oil testing and identify trends and anomalies, providing empowered maintenance decisions. As reliability and effectiveness are paramount, partnering with accredited testing facilities ensures adherence to the latest international standards and methodologies. Expert technicians with a deep understanding of transformer maintenance dynamics are quintessential to applying tests in a way that translates to meaningful insights. Their role is pivotal, embodying trustworthiness and authority in maintaining electrical transmission integrity. The significance of transformer oil testing cannot be overstated, playing a crucial role in electrical network stability and operational efficiency. Regular, thorough testing not only optimizes transformer performance but champions a company’s commitment to adopting prudent, well-informed maintenance practices indispensable in today’s dynamic, competitive marketplace.

Interfacial Tension (IFT) Testing measures the oil's ability to maintain a barrier against moisture penetration. Low IFT values signify contamination or oxidation, which prompts further investigative measures or oil purification processes. Monitoring IFT offers an additional layer to ensuring the robustness of transformer oil insulation. By leveraging the outcomes from these transformer oil tests, companies can ensure a proactive maintenance strategy that significantly extends equipment life, reduces the risk of downtime, and enhances safety standards. Consistent monitoring and testing align closely with industry-established benchmarks and best practices, safeguarding the substantial investments placed in electrical infrastructure. In the context of emerging technological advancements, transformer oil testing also embraces digitalization through automated testing solutions that ensure greater precision and reduced human error. AI-powered diagnostic tools can continuously interpret data derived from oil testing and identify trends and anomalies, providing empowered maintenance decisions. As reliability and effectiveness are paramount, partnering with accredited testing facilities ensures adherence to the latest international standards and methodologies. Expert technicians with a deep understanding of transformer maintenance dynamics are quintessential to applying tests in a way that translates to meaningful insights. Their role is pivotal, embodying trustworthiness and authority in maintaining electrical transmission integrity. The significance of transformer oil testing cannot be overstated, playing a crucial role in electrical network stability and operational efficiency. Regular, thorough testing not only optimizes transformer performance but champions a company’s commitment to adopting prudent, well-informed maintenance practices indispensable in today’s dynamic, competitive marketplace.

Previous:

Latest news

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024