English

English

Transformer Evaluation and Operational Readiness Assessment for Enhanced Performance

Transformer Testing and Commissioning Ensuring Reliability and Performance

Transformers are critical components in electrical power systems, responsible for converting voltage levels to facilitate the efficient transmission and distribution of electrical energy. The testing and commissioning of transformers are essential processes to ensure their reliability, performance, and safety. This article outlines the key aspects of transformer testing and commissioning, emphasizing their importance in the overall infrastructure of electrical systems.

The Importance of Testing

Transformer testing is crucial to confirm that the equipment operates within specified parameters before it is put into service. This process helps identify any potential issues that could lead to failures, reduce downtime, and ensure the longevity of the transformer. Testing activities can be categorized into two main types routine tests and type tests.

Routine Tests These are conducted on every transformer before it is commissioned. They verify the basic operational functionality, including insulation resistance, turns ratio, and power factor. Routine tests help ensure that the transformer meets the manufacturer’s specifications and standards defined by industry authorities.

Type Tests In contrast, type tests are performed on a sample of transformers to verify their compliance with applicable standards under specific operational conditions. These tests evaluate aspects such as temperature rise, short-circuit resistance, and dielectric strength. The outcomes provide assurance that transformers will perform reliably in their intended applications.

Key Testing Procedures

Several critical tests are commonly conducted during the transformer testing phase

1. Insulation Resistance Testing This test measures the resistance of the insulation material to determine its integrity. High insulation resistance indicates a healthy transformer, reducing the risk of electrical faults.

2. Transformer Turns Ratio (TTR) Testing This test evaluates the ratio of the primary winding turns to the secondary winding turns. An incorrect turns ratio can lead to voltage discrepancies, impacting the performance of the entire electrical system.

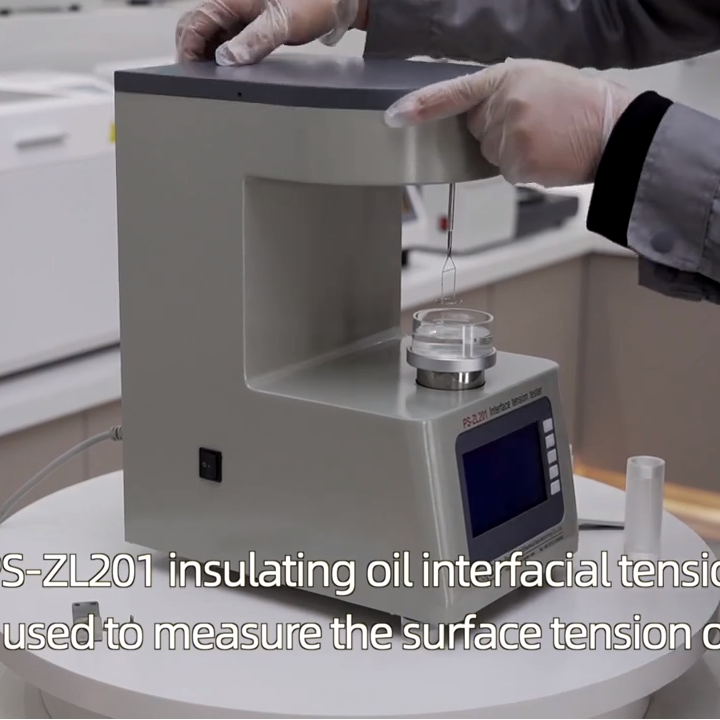

3. Power Factor Testing This assesses the dissipation factor of the transformer insulation, providing insight into its condition. A lower power factor indicates better insulation quality, while a higher value may suggest deterioration.

transformer testing and commissioning

4. bushing capacitance and power factor tests Bushing systems are crucial for voltage transformation, and these tests ensure their operational integrity and safety under high voltage.

5. Leakage Reactance Testing This involves measuring the leakage reactance of the transformer to predict the voltage drop and potential losses during operation.

Commissioning Procedures

Once testing is complete and satisfactory results are achieved, the commissioning phase begins. Commissioning involves initializing the transformer and integrating it into the electrical system. This process includes

- Visual Inspection A thorough examination of the transformer and its components to identify any physical damage or manufacturing defects.

- Connections Verification Ensuring that all electrical connections, including grounding and protective devices, are properly installed and secure.

- Functional Testing This involves performing a series of tests under operational conditions to evaluate the transformer's functionality and interaction with the network. Load testing is often a critical part of this phase, verifying the transformer’s behavior under peak operational loads.

- Final Documentation Once commissioning is complete, all tests and inspections are documented. This information is essential for future maintenance, troubleshooting, and system upgrades.

Conclusion

The testing and commissioning of transformers are pivotal in safeguarding the reliability and performance of electrical power systems. By conducting thorough tests, operators can identify potential issues early, thereby avoiding costly failures and ensuring the safe, efficient operation of electrical networks. As power demands increase and technology evolves, adhering to stringent testing and commissioning protocols becomes increasingly vital for maintaining the integrity of electrical infrastructure. Investing in these processes not only prolongs the lifespan of transformers but also enhances the overall stability and efficiency of power distribution systems.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024