English

English

Measuring Transformer Winding Resistance Using Advanced Metering Techniques for Accurate Testing

Understanding Transformer Winding Resistance Meters

Transformer winding resistance meters are essential instruments used in the testing and maintenance of electrical transformers. These devices play a critical role in ensuring the reliability and efficiency of transformers, which are vital components in power distribution systems. With the increasing demand for electrical energy and the need for reliable infrastructure, the importance of transformer diagnostic tools, like winding resistance meters, has grown significantly.

What is a Transformer Winding Resistance Meter?

A transformer winding resistance meter is designed to measure the resistance of the winding coils in transformers. Winding resistance is crucial because it affects the transformer's performance, efficiency, and longevity. Excessive resistance in transformer windings can indicate potential problems such as loose connections, corrosion, or even short circuits, which could lead to transformer failure if not addressed.

The meter typically employs a low-frequency AC or DC current to measure resistance. The current is passed through the winding, and the resulting voltage drop is measured to calculate the resistance using Ohm's law (R = V/I). This simple yet effective method provides technicians with accurate readings essential for diagnostics and maintenance.

Importance of Winding Resistance Testing

Regular testing of winding resistance is crucial for several reasons. First, it helps identify issues before they develop into significant problems. For instance, increased resistance can suggest the presence of moisture or contamination within the winding or deteriorated insulation. Detecting these issues early can prevent costly downtime and repairs.

Furthermore, measuring the winding resistance can help ensure compliance with industry standards and specifications. Many manufacturers specify acceptable resistance ranges for their transformers; regular testing ensures that these parameters are met, indicating the equipment operates efficiently and safely.

Testing Procedure

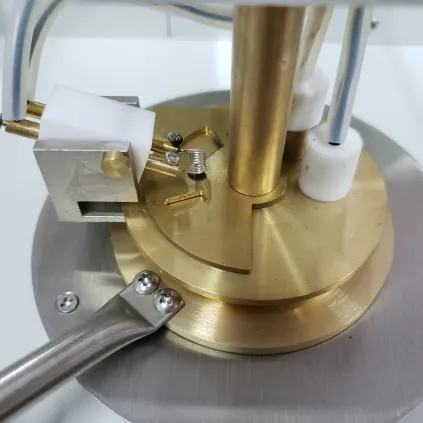

transformer winding resistance meter

The procedure for testing transformer winding resistance usually involves several critical steps. Initially, the technician ensures that the transformer is offline, and all appropriate safety measures are taken to eliminate the risk of electric shock. Then, connections are made between the winding resistance meter and the transformer winding terminals.

Once connected, the technician sets the meter to the appropriate range and initiates the test. The meter will display the resistance value after the calculation is complete. Multiple measurements may be taken on different windings (primary and secondary) to ensure a comprehensive assessment of the transformer’s condition.

It’s also common to perform tests at varying temperatures and record these values. This is important because resistance readings can fluctuate with temperature changes, and technicians often use these values to calculate the expected resistance under standard conditions.

Advantages of Using Transformer Winding Resistance Meters

Using a transformer winding resistance meter offers several advantages. These devices are designed to provide quick and accurate resistance measurements, making them invaluable for technicians working in the field. With advances in technology, modern meters are often equipped with functionalities such as data logging, connectivity options, and automated reporting features. This allows for easier record-keeping and trend analysis, thereby streamlining the maintenance processes.

Additionally, some advanced models are capable of conducting multiple tests, including capacitance and power factor tests, within the same instrument. This versatility enhances their utility and makes them a staple tool for electrical engineers and maintenance crews.

Conclusion

In conclusion, transformer winding resistance meters are integral to the maintenance and operation of transformers in electrical systems. They help ensure the reliability and efficiency of transformers by allowing for early detection of potential issues through routine resistance testing. As technology evolves, these instruments are becoming increasingly sophisticated, offering improved accuracy and functionality, which can be pivotal in managing the complexities of modern electrical infrastructure. Regular use of winding resistance meters can greatly contribute to minimizing unplanned outages and extending the lifespan of transformer assets, ultimately supporting the efficient dissemination of electrical power.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024