English

English

Understanding the D1816 Dielectric Test and Its Applications in Electrical Engineering

Understanding the D1816 Dielectric Test Importance and Applications

The D1816 dielectric test is a vital diagnostic tool widely used in the electrical engineering field for evaluating the dielectric strength of insulation materials. Dielectric strength is a critical factor in ensuring the reliability and safety of electrical systems. By understanding the principles and applications of the D1816 dielectric test, professionals can make informed decisions about material selection, maintenance, and overall system safety.

Understanding the D1816 Dielectric Test Importance and Applications

The test is typically conducted using a specific setup that involves applying a steadily increasing AC voltage to the insulation material until it breaks down. The voltage at which breakdown occurs is recorded as the dielectric strength. To ensure accuracy and repeatability, the test must adhere to strict conditions concerning temperature, humidity, and other environmental factors. The D1816 standard specifies these conditions, making it a reliable reference for manufacturers and engineers alike.

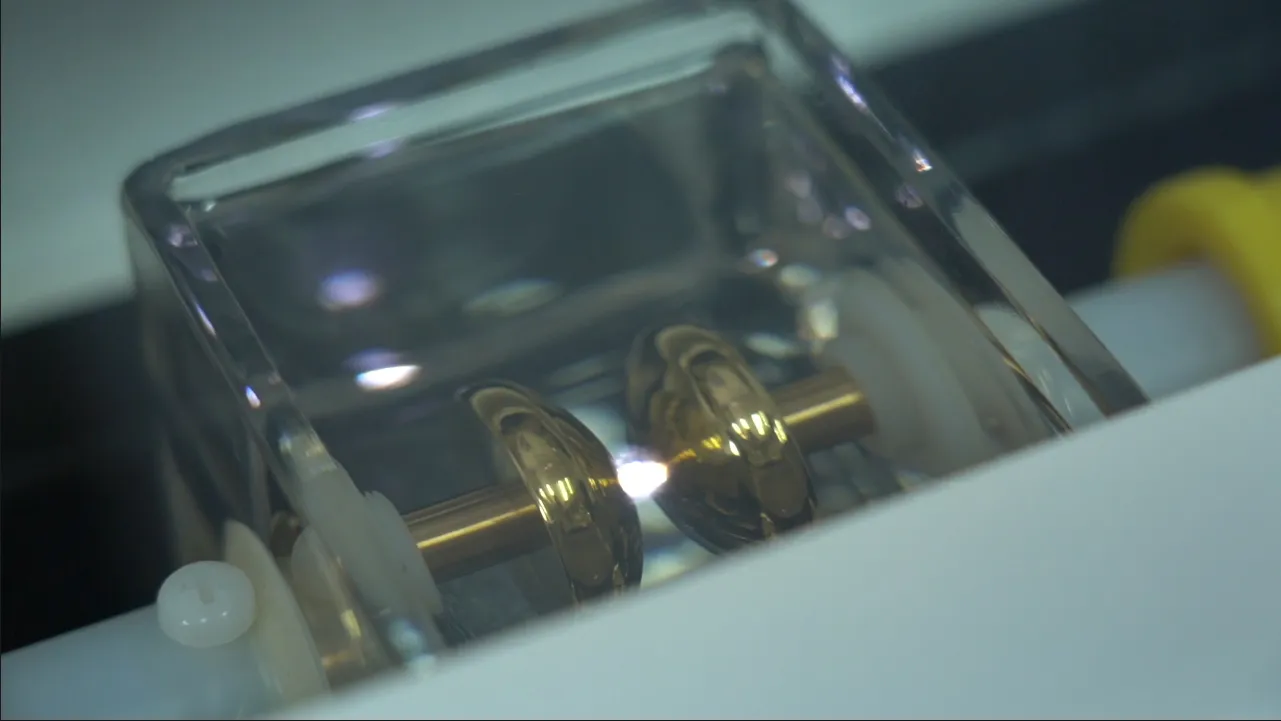

d1816 dielectric test

One of the most significant aspects of the D1816 dielectric test is its application in the production and quality control of electrical insulation materials. Manufacturers of cables, transformers, capacitors, and various other electrical components rely on this testing to guarantee that the materials they use meet industry standards. For instance, a cable with a low dielectric strength might not perform effectively under high voltage, leading to failures that could result in costly downtimes or even hazardous situations.

Moreover, the D1816 dielectric test plays a crucial role in the maintenance of existing electrical systems. Over time, insulation materials can degrade due to factors such as heat, mechanical stress, and environmental conditions. Regular testing using the D1816 standard can help identify potential insulation breakdowns before they lead to catastrophic failures. By proactively assessing the dielectric strength of insulation materials, engineers can schedule repairs or replacements, thereby avoiding system outages and ensuring continuous operation.

Furthermore, safety regulations in many industries mandate the testing of insulation materials to prevent electrical hazards. The D1816 dielectric test, therefore, not only serves as a quality assurance tool but also helps organizations comply with safety standards. This compliance is essential for protecting personnel, equipment, and the surrounding environment, especially in high-stakes industries such as power generation, manufacturing, and aerospace.

In conclusion, the D1816 dielectric test is an indispensable method for assessing the dielectric strength of insulation materials, ensuring the reliability and safety of electrical systems. Its applications in manufacturing and maintenance highlight the importance of this test in preventing failures, maintaining system integrity, and complying with safety regulations. As technology continues to advance, the relevance of reliable dielectric testing will only increase, underscoring the need for adherence to established standards like D1816 in the electrical engineering field. By investing in proper testing and quality assurance measures, engineers and organizations can safeguard their systems and ensure efficient operation, thereby supporting the ever-growing demands of modern electrical infrastructure.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024