English

English

Understanding the Importance of Electrical Insulation Resistance Testing for Safe Electrical Systems

Understanding Electrical Insulation Resistance Testing

Electrical insulation resistance testing is a critical procedure in the field of electrical engineering. It serves as a fundamental method for assessing the effectiveness of the insulation material that protects electrical systems. Insulation resistance testing helps to ensure the reliability and safety of electrical installations, preventing catastrophic failures and ensuring compliance with safety standards.

The Importance of Insulation Resistance Testing

Insulation resistance is a measure of how well the insulating materials of electrical systems can resist the flow of electric current. Over time, insulation can degrade due to environmental factors, mechanical stress, or thermal influences, leading to increased risk of electrical faults, short circuits, and potential electrical shocks. Conducting regular insulation resistance tests is essential for maintaining the safety and efficiency of electrical systems.

The primary reason behind conducting these tests is to identify the current state of insulation and to detect any potential issues before they escalate into serious problems. By measuring insulation resistance, engineers can evaluate whether the insulation is still effective and if it meets the necessary resistance thresholds.

Methods of Insulation Resistance Testing

There are several methods for conducting insulation resistance testing, but the most widely used involves the application of a known voltage across the insulation material. The procedure typically includes the following steps

1. Preparation Before testing, electrical equipment should be turned off and disconnected from any power source. Safety precautions must be taken to avoid any electrical hazards.

electrical insulation resistance testing

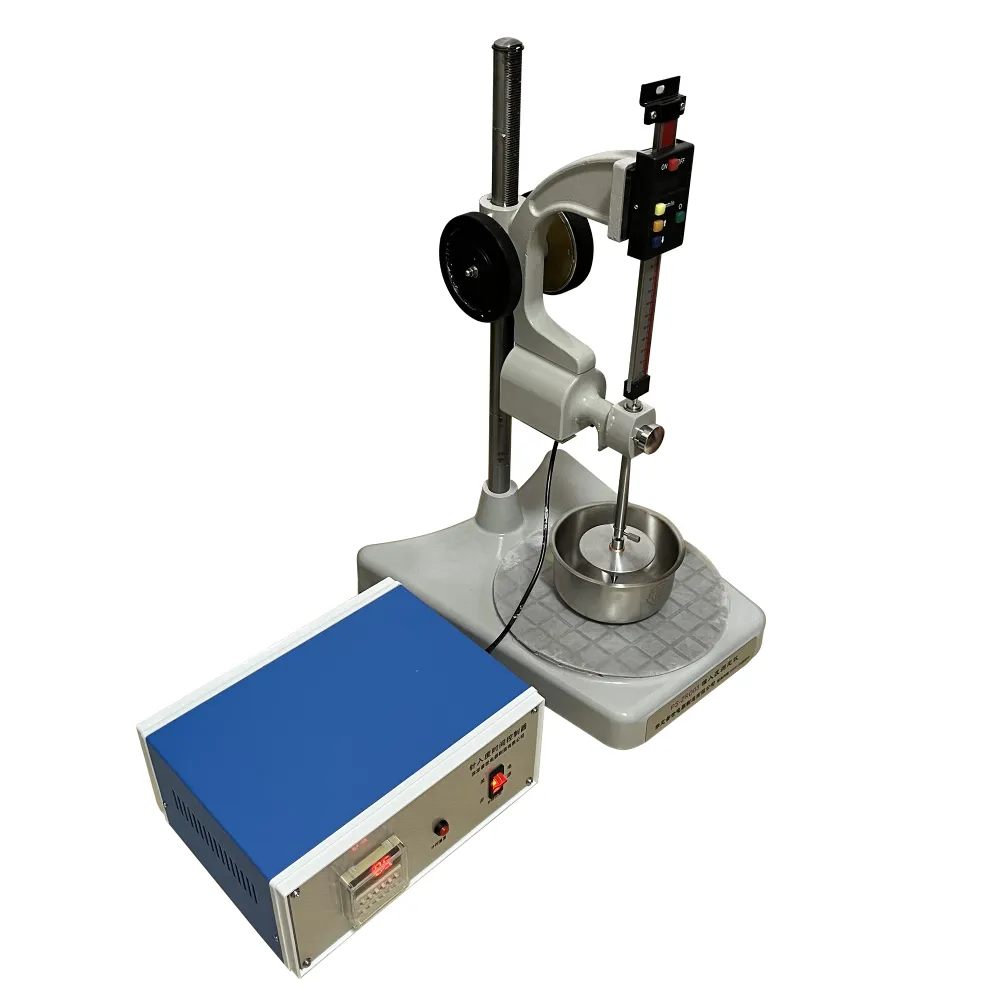

2. Testing Voltage A testing device called a megohmmeter (or insulation resistance tester) is used. This device applies a high DC voltage (commonly 250V, 500V, or 1000V) to the insulation for a specified duration. This voltage stresses the insulation and encourages any current leakage to be measured accurately.

3. Measurement As the voltage is applied, the megohmmeter measures the current flowing through the insulation. This current, when compared to the applied voltage, allows for calculating the insulation resistance in ohms (Ω).

4. Analysis The results are compared against predetermined standards or historical data for the specific installation. A residual resistance value below the acceptable threshold indicates possible insulation failure or deterioration.

Interpreting Test Results

Understanding the results of insulation resistance tests is crucial. Generally, higher resistance values indicate better insulation quality. The criteria for acceptable resistance values can vary based on the equipment being tested, the application, and industry standards. Common benchmarks suggest that insulation resistance should be above 1 megohm for most applications, although different equipment and contexts may have specific requirements.

If a test reveals low insulation resistance, further investigation is warranted. This may involve visual inspections, thermographic surveys, or even further electrical testing to identify the source of the problem, such as moisture ingress, insulation wear, or physical damage.

Conclusion

In summary, electrical insulation resistance testing is a vital practice in maintaining the safety and reliability of electrical systems. Regular testing helps identify potential problems early, thereby reducing the risk of failures and ensuring compliance with safety regulations. As technology advances, embracing new testing methods will enhance the effectiveness of insulation resistance testing, leading to safer and more efficient electrical infrastructure. Adequate training and knowledge in this area are essential for professionals tasked with maintaining electrical systems, safeguarding equipment, and, most importantly, protecting lives.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024