English

English

Understanding the Importance of Hipot Testing for Ensuring Electrical Safety and Equipment Reliability

Understanding Hipot Testing for Electrical Safety

In today’s world, where electrical devices and appliances are ubiquitous, ensuring their safety is paramount. One crucial method employed in this regard is a process known as hipot testing, or high potential testing. This testing method is designed to ensure that electrical insulation within devices is adequate and can withstand high voltage situations, thus preventing electrical shocks, fires, and other hazards.

What is Hipot Testing?

Hipot testing is a type of electrical safety test that applies a high voltage to an electrical device’s insulation system. The principle behind this test is relatively straightforward by subjecting the device to a voltage that exceeds its normal operational levels, the test evaluates whether the insulation can withstand such stress without allowing current to leak through. This leakage can lead to dangerously hazardous conditions, making hypoth testing a critical component in electrical safety evaluations.

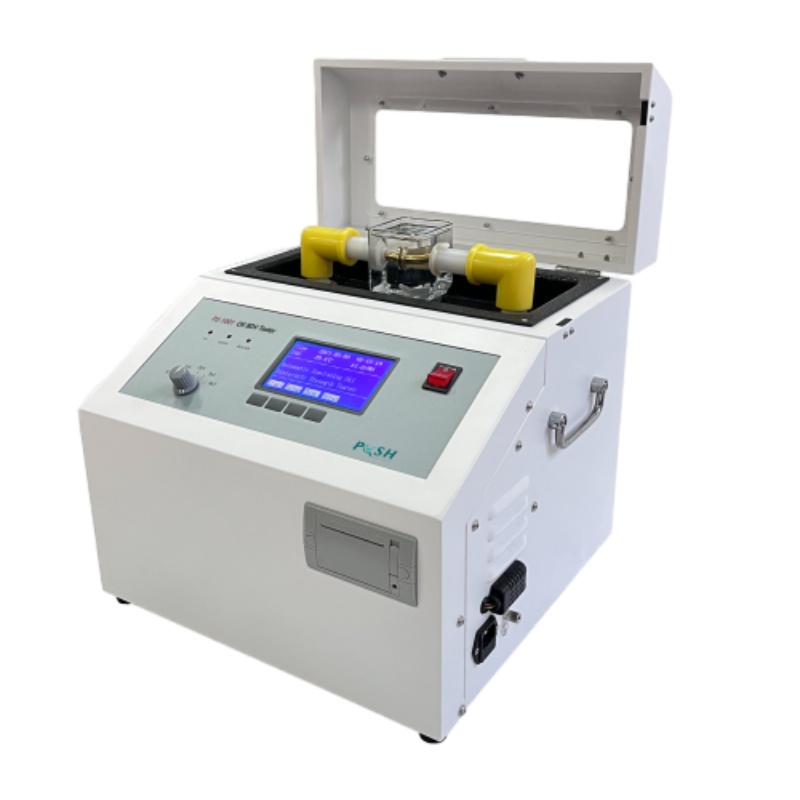

The test typically involves using a hipot tester, which applies AC or DC voltage (usually much higher than the device’s operational voltage) to the insulation between the electrical components and the ground. A common testing voltage might range from 1,000 volts to several thousand volts, depending on the type of equipment being tested.

Importance of Hipot Testing

The primary purpose of hipot testing is to verify the integrity of electrical insulation. Electrical devices, especially those that are consumer-facing, need to provide a high level of safety to prevent shock hazards. Insulation can degrade over time due to various factors, including heat, moisture, and wear-and-tear. By conducting hipot tests, manufacturers can ensure that their products are safe for consumers and comply with safety standards set by regulatory bodies.

hipot test safety

Moreover, hipot testing is crucial for the prevention of electrical fires. Faulty insulation can lead to short circuits, which can ignite flammable materials nearby. Ensuring that the insulation within various devices, from power supplies and cords to household appliances, is robust enough can mitigate these risks.

Testing Procedures and Standards

When conducting a hipot test, it is crucial to follow specific industry standards. Different sectors may have different requirements depending on the type of equipment being tested. For example, the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL) provide guidelines that help manufacturers ascertain the appropriate testing methodology.

During the hipot test, a detailed procedure is typically followed the device is connected to the hipot tester, and the designated high voltage is applied for a specified duration. During this time, the tester monitors for signs of insulation failure, such as current leakage. If the test reveals excessive leakage currents or insulation breakdown, the device fails, indicating that it requires further inspection or redesign before it is deemed safe for use.

Conclusion

Hipot testing is a cornerstone of electrical safety verification in the modern world. As technology continues to evolve, the range of devices that necessitate such testing grows. Manufacturers must prioritize these safety measures to protect consumers and ensure compliance with regulatory standards. In this ever-connected age, where the safety of electrical devices is integral to public welfare, metallurgical and electrical engineers must continuously advocate and implement robust testing protocols like hipot testing to ensure that our reliance on technology remains safe and secure. Whether it’s a simple charger or complex industrial machinery, hipot testing plays a vital role in safeguarding lives.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024