TEL:

+86-0312-3189593

English

English

Telephone:0312-3189593

Email:sales@oil-tester.com

1 月 . 15, 2025 09:49

Back to list

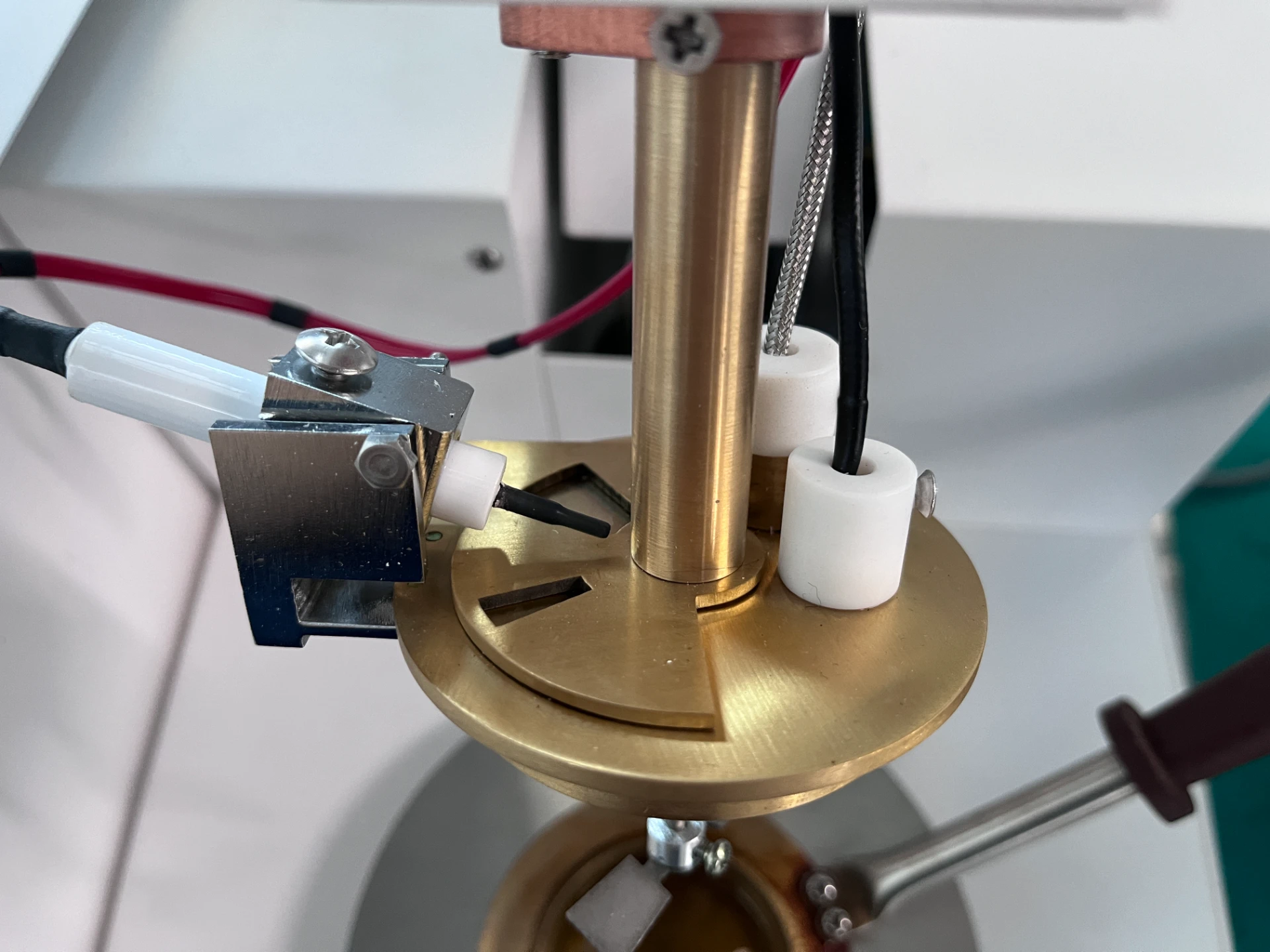

PUSH electric Manual oil cup cleaning type insulating oil dielectric loss and volume resistivity tester

Understanding the intricacies of choosing the right viscometer for oil is crucial for anyone invested in ensuring optimal performance and accuracy in various industrial applications. As an authoritative voice in the field of rheological measurement, this article will guide you through the essential factors that influence the selection of an ideal viscometer for oil testing, offering insights grounded in years of expertise and tested experience.

Being an authoritative figure in the field necessitates staying abreast of technological advancements in viscometers. Modern devices equipped with digital interfaces and automated data logging systems simplify the measurement process, reduce human error, and enhance data integrity, thus fostering more reliable laboratory results. Innovations such as real-time viscosity data tracking and remote monitoring are revolutionizing how industries approach oil testing, providing unparalleled insights and streamlining the workflow. Experience has also shown that regular maintenance and calibration of viscometers significantly impact their performance and longevity. Establishing a routine calibration schedule not only extends the device's life but also ensures that the measurement outputs remain consistently reliable and accurate. Proper calibration techniques are integral to maintaining equipment authority and facilitating repeatable measurements, thereby enhancing trustworthiness in data outputs. In conclusion, the decision to invest in a viscometer for oil involves more than just choosing a tool—it's about selecting a partner in quality assurance and operational excellence. By considering factors such as the type of viscometer, viscosity range, temperature sensitivity, technological advancements, and maintenance, businesses can ensure precise, reliable, and authoritative viscosity measurements that are critical for optimal operational performance. With these insights, one can confidently traverse the complexities of viscometric analysis, harnessing its full potential for their specific industrial requirements.

Being an authoritative figure in the field necessitates staying abreast of technological advancements in viscometers. Modern devices equipped with digital interfaces and automated data logging systems simplify the measurement process, reduce human error, and enhance data integrity, thus fostering more reliable laboratory results. Innovations such as real-time viscosity data tracking and remote monitoring are revolutionizing how industries approach oil testing, providing unparalleled insights and streamlining the workflow. Experience has also shown that regular maintenance and calibration of viscometers significantly impact their performance and longevity. Establishing a routine calibration schedule not only extends the device's life but also ensures that the measurement outputs remain consistently reliable and accurate. Proper calibration techniques are integral to maintaining equipment authority and facilitating repeatable measurements, thereby enhancing trustworthiness in data outputs. In conclusion, the decision to invest in a viscometer for oil involves more than just choosing a tool—it's about selecting a partner in quality assurance and operational excellence. By considering factors such as the type of viscometer, viscosity range, temperature sensitivity, technological advancements, and maintenance, businesses can ensure precise, reliable, and authoritative viscosity measurements that are critical for optimal operational performance. With these insights, one can confidently traverse the complexities of viscometric analysis, harnessing its full potential for their specific industrial requirements.

Latest news

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024