English

English

winding resistance test of transformer

Winding Resistance Test of Transformers

The winding resistance test is a critical diagnostic procedure performed on transformers to assess their electrical and mechanical integrity. This test measures the resistance of the transformer windings, which can provide valuable insights into the condition of the transformer and help ensure its efficient operation.

Transformers are essential components in electrical systems, responsible for stepping up or stepping down voltage levels to facilitate efficient power transmission and distribution. Over time, windings may experience deterioration due to factors such as thermal aging, moisture ingress, or mechanical stress. Performing a winding resistance test helps identify issues such as loose connections, defective joints, or compromised insulation that could lead to operational failures.

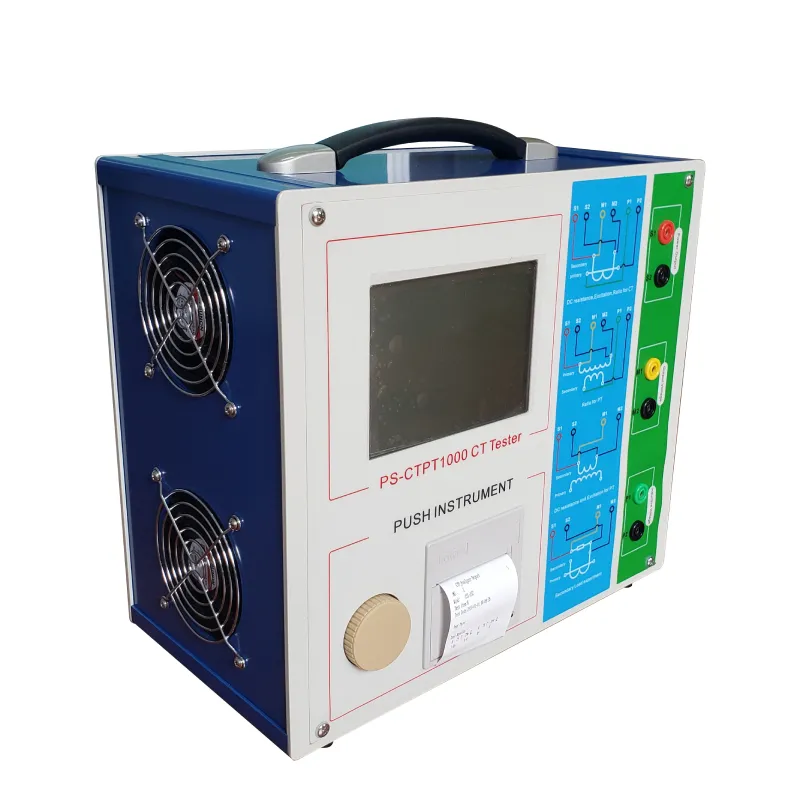

The winding resistance test is typically conducted using a low-resistance ohmmeter or a specialized winding resistance tester. The procedure involves disconnecting the transformer from the power supply and other electrical circuits to ensure safety and accuracy. Once the transformer is isolated, the tester is connected across the windings, and a current is injected to measure the voltage drop across the windings. Ohm’s law (V = IR) can then be applied to calculate the resistance.

One of the key parameters evaluated during this test is the resistance ratio between the primary and secondary windings. Significant deviations from expected resistance values can indicate problems such as poor connections or winding faults. Additionally, the test results can reveal temperature variations within the windings, which can be critical for assessing overheating issues.

winding resistance test of transformer

It is essential to conduct the winding resistance test under controlled temperature conditions, as resistance values can change with temperature fluctuations. Therefore, corrections should be applied to obtained resistance readings to reflect the standard temperature, typically 20°C. This allows for accurate comparisons of resistance values during subsequent tests, which is crucial for trend analysis over time.

Regular winding resistance testing helps in the proactive maintenance of transformers. By establishing a baseline during initial commissioning and comparing it with future test results, maintenance teams can track the condition of the transformer windings. This approach not only aids in identifying potential failures before they occur but also assists in scheduling maintenance activities more effectively, thus reducing unplanned outages and enhancing system reliability.

Moreover, winding resistance tests are often performed in conjunction with other routine diagnostic tests such as insulation resistance tests, power factor testing, and thermal imaging. This comprehensive testing regime allows for a holistic assessment of transformer health, ensuring long-term operational reliability.

In conclusion, the winding resistance test is a vital tool in the maintenance and reliability strategy for transformers. By routinely conducting this test, utilities and facility managers can detect impending issues early, ensure efficient performance, and extend the lifespan of their transformers, thereby safeguarding critical electrical infrastructure.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024