TEL:

+86-0312-3189593

English

English

Telephone:0312-3189593

Email:sales@oil-tester.com

1 月 . 26, 2025 02:18

Back to list

PUSH electrical astm d93 close cup flash point tester Silicon nitride ignition head

In the ever-evolving world of distillation technology, automatic distillation stands out as a hallmark of innovation, offering unparalleled efficiency and precision. This advanced technique is revolutionizing industries ranging from oil refining to beverage production. By incorporating cutting-edge automation, companies can now optimize their distillation processes, resulting in higher quality products and significant cost savings.

Trustworthiness is another critical aspect of automatic distillation. The technology is backed by rigorous testing and validation processes, ensuring its reliability under various operational scenarios. Manufacturers of automatic distillation equipment often provide comprehensive training and support, empowering operators with the knowledge required to maximize system capabilities. This commitment to customer education further reinforces trust in the technology. In a product-focused context, automatic distillation systems offer tangible benefits that directly impact the bottom line. Companies can expect to see reduced operational costs, improved product quality, and increased throughput. Additionally, the ability to quickly adapt to changing market demands or raw material variations provides businesses with a competitive edge. Looking towards the future, the integration of artificial intelligence and machine learning with automatic distillation systems promises even greater advancements. These technologies can further enhance system intelligence, enabling predictive maintenance and smarter process control. This evolution will undoubtedly solidify automatic distillation as an indispensable tool for modern industries seeking to remain competitive in an ever-changing marketplace. In conclusion, automatic distillation represents a fusion of experience, expertise, authoritativeness, and trustworthiness. It is a technology that not only meets the demands of today’s production environments but also sets the stage for future innovations. Businesses that embrace this technology can expect to see significant improvements in their performance metrics, ultimately leading to a more sustainable and profitable operation.

Trustworthiness is another critical aspect of automatic distillation. The technology is backed by rigorous testing and validation processes, ensuring its reliability under various operational scenarios. Manufacturers of automatic distillation equipment often provide comprehensive training and support, empowering operators with the knowledge required to maximize system capabilities. This commitment to customer education further reinforces trust in the technology. In a product-focused context, automatic distillation systems offer tangible benefits that directly impact the bottom line. Companies can expect to see reduced operational costs, improved product quality, and increased throughput. Additionally, the ability to quickly adapt to changing market demands or raw material variations provides businesses with a competitive edge. Looking towards the future, the integration of artificial intelligence and machine learning with automatic distillation systems promises even greater advancements. These technologies can further enhance system intelligence, enabling predictive maintenance and smarter process control. This evolution will undoubtedly solidify automatic distillation as an indispensable tool for modern industries seeking to remain competitive in an ever-changing marketplace. In conclusion, automatic distillation represents a fusion of experience, expertise, authoritativeness, and trustworthiness. It is a technology that not only meets the demands of today’s production environments but also sets the stage for future innovations. Businesses that embrace this technology can expect to see significant improvements in their performance metrics, ultimately leading to a more sustainable and profitable operation.

Latest news

-

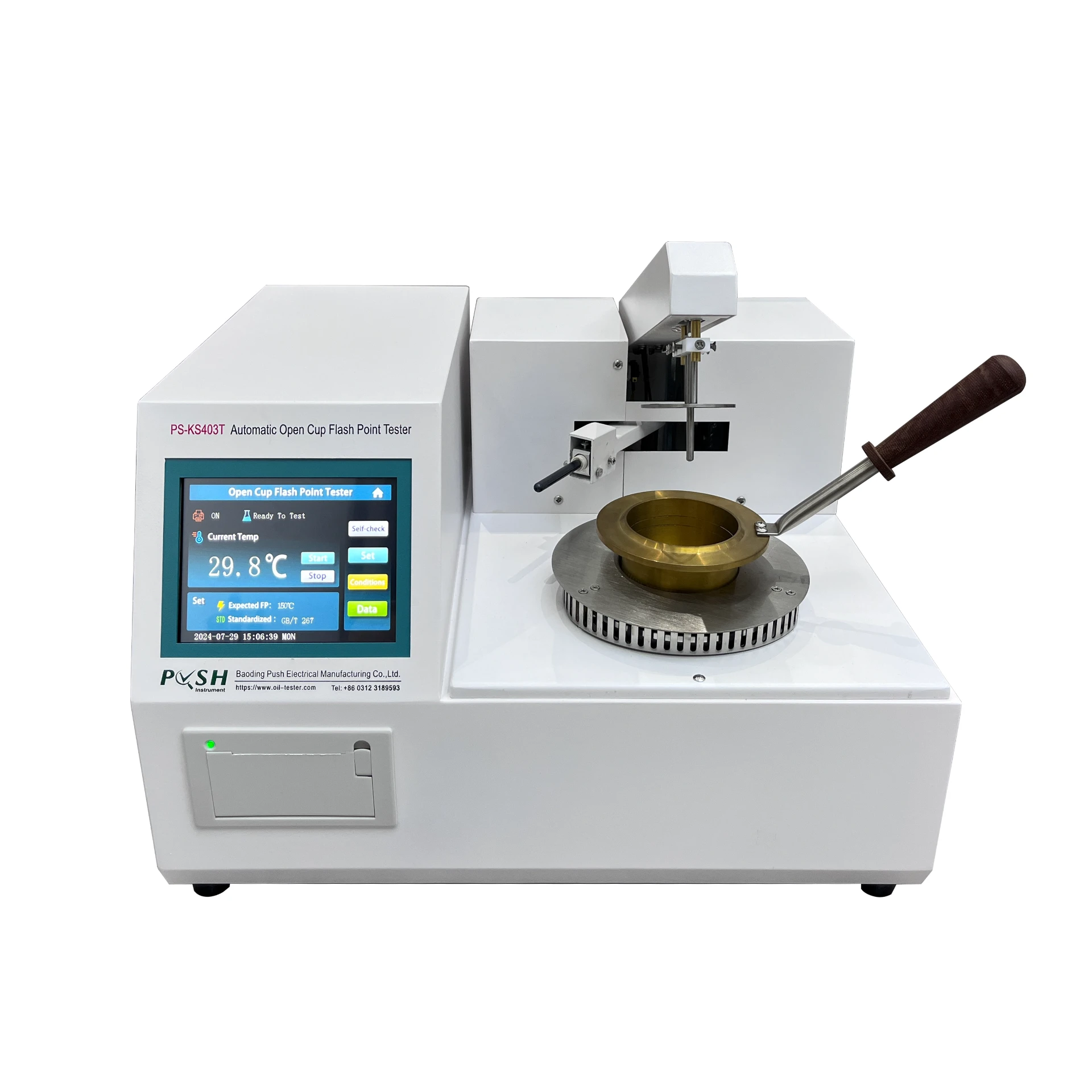

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024