TEL:

+86-0312-3189593

English

English

Telephone:0312-3189593

Email:sales@oil-tester.com

2 月 . 06, 2025 05:15

Back to list

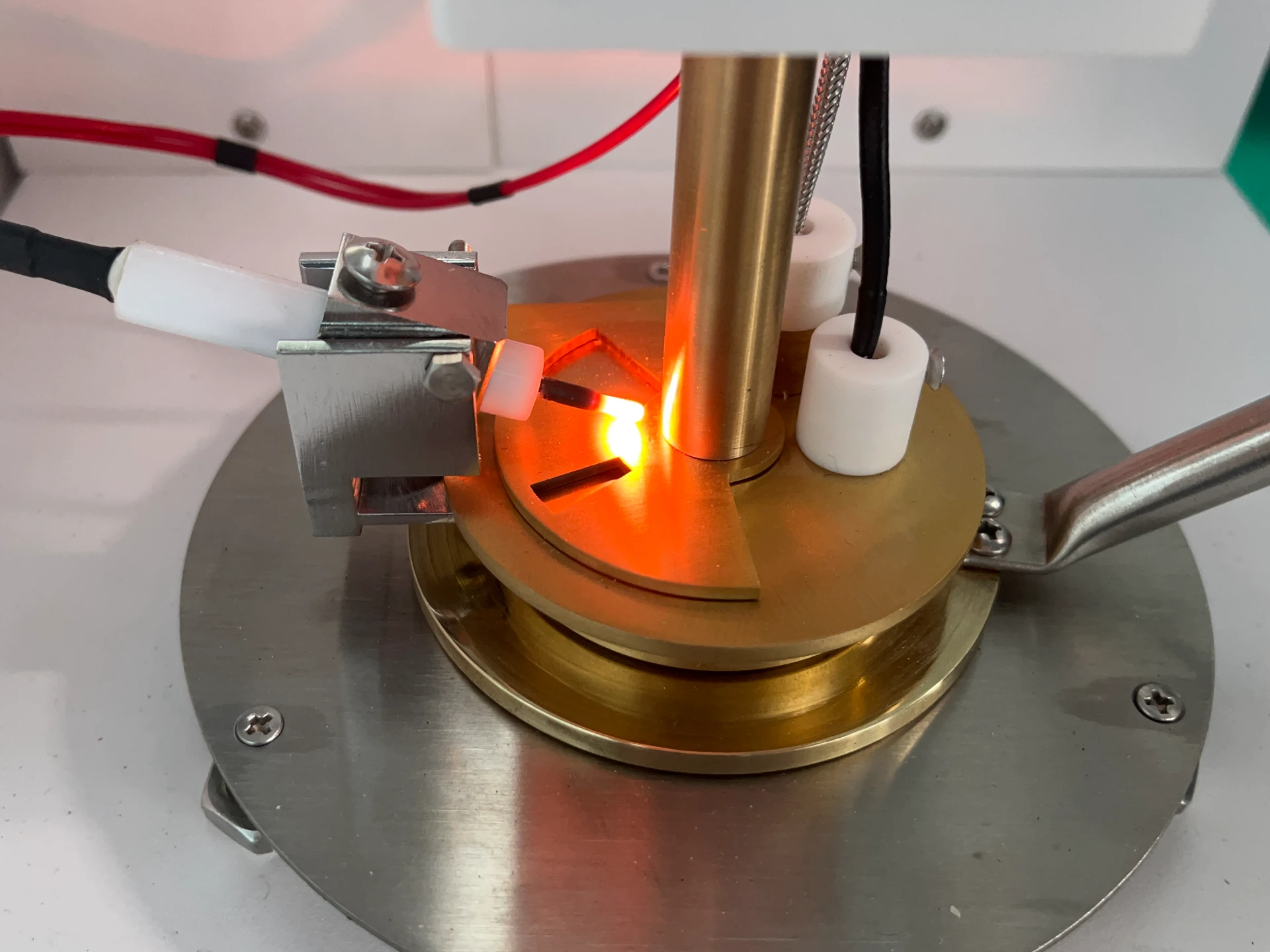

Transformer insulation oil breakdown voltage tester bdv

Capacitance and dissipation factor testing of transformers have become integral components of modern transformer diagnostics. These tests aid in the identification of issues related to insulation, which is crucial for the efficient and safe operation of transformers. Variables like moisture content and temperature can impact transformer health, making the role of regular testing even more critical.

Ensuring authority in discussing capacitance and dissipation factor testing requires in-depth knowledge not just of the procedures, but also of the specific transformer types, ages, and operating environments. Technical guidance on these tests often cites international standards such as those from the International Electrotechnical Commission (IEC), ensuring that practices align with globally recognized criteria. Trustworthiness in diagnostic testing and subsequent interpretation is often built by generating consistent, verifiable data across maintenance cycles. This consistency allows asset managers to observe trends over time, facilitating proactive maintenance strategies. Essentially, a trustworthy approach not only resolves immediate issues but also offers predictive insights that align with strategic maintenance schedules. This can result in cost savings by preventing catastrophic failures and optimizing the usability of transformer assets. One real-world example comes from utility companies that conduct regular capacitance and dissipation tests as part of their transformer fleet management. Field experience suggests that transformers showing early signs of insulation degradation identified through these tests can often be remediated or refurbished under controlled conditions. Preventive measures, reinforced through reliable test data, ensure extended transformer life and operational safety. In conclusion, capacitance and dissipation factor testing is an essential pillar in transformer management for its role in enhancing reliability, maintaining safety, and extending service life. Successful implementation requires a harmonious blend of technical precision, professional expertise, adherence to authoritative standards, and a trustworthy framework for ongoing monitoring and diagnostics. By leveraging these aspects, stakeholders can ensure optimal performance of transformers and, by extension, the power systems they support.

Ensuring authority in discussing capacitance and dissipation factor testing requires in-depth knowledge not just of the procedures, but also of the specific transformer types, ages, and operating environments. Technical guidance on these tests often cites international standards such as those from the International Electrotechnical Commission (IEC), ensuring that practices align with globally recognized criteria. Trustworthiness in diagnostic testing and subsequent interpretation is often built by generating consistent, verifiable data across maintenance cycles. This consistency allows asset managers to observe trends over time, facilitating proactive maintenance strategies. Essentially, a trustworthy approach not only resolves immediate issues but also offers predictive insights that align with strategic maintenance schedules. This can result in cost savings by preventing catastrophic failures and optimizing the usability of transformer assets. One real-world example comes from utility companies that conduct regular capacitance and dissipation tests as part of their transformer fleet management. Field experience suggests that transformers showing early signs of insulation degradation identified through these tests can often be remediated or refurbished under controlled conditions. Preventive measures, reinforced through reliable test data, ensure extended transformer life and operational safety. In conclusion, capacitance and dissipation factor testing is an essential pillar in transformer management for its role in enhancing reliability, maintaining safety, and extending service life. Successful implementation requires a harmonious blend of technical precision, professional expertise, adherence to authoritative standards, and a trustworthy framework for ongoing monitoring and diagnostics. By leveraging these aspects, stakeholders can ensure optimal performance of transformers and, by extension, the power systems they support.

Latest news

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024