TEL:

+86-0312-3189593

English

English

Telephone:0312-3189593

Email:sales@oil-tester.com

2 月 . 06, 2025 05:39

Back to list

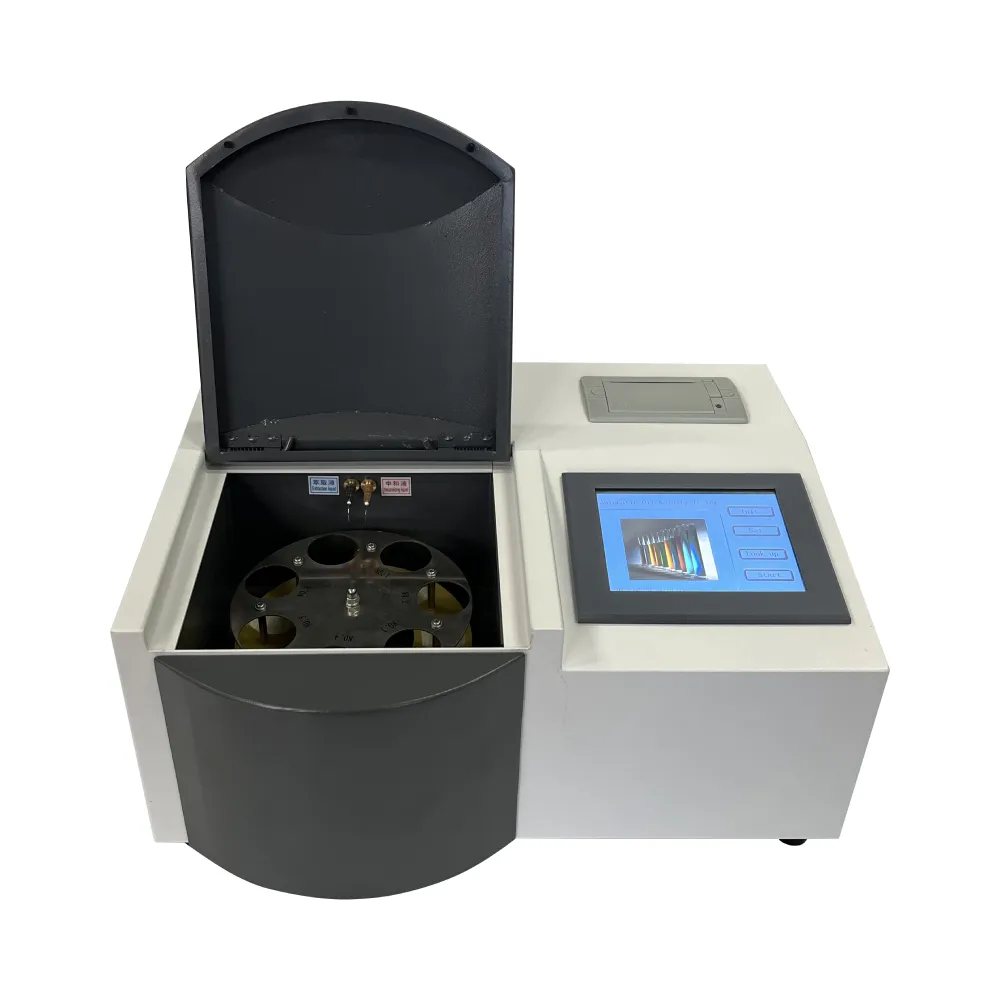

PS-JSB01 Transformer Dielectric Loss Analysis Tan Delta Tester

Capacitance and tan delta measurement are critical aspects in assessing the health and efficiency of electrical equipment such as transformers, cables, and capacitors. Understanding these measurements is fundamental for ensuring the longevity and reliability of electrical systems, and making informed decisions when it comes to maintenance and troubleshooting.

As authoritative figures in electrical testing domains stress, adherence to standards such as those set by IEEE and IEC is essential. These standards ensure uniformity in testing methods and results, promoting trust and credibility in the findings. For instance, critical values and acceptable ranges for capacitance and tan delta differ across equipment types and industry applications, as specified in these guidelines. Establishing trustworthiness involves transparent reporting and analysis of measurement outcomes. For those in asset management, providing clear reports that break down complex data into actionable insights is crucial. This includes detailed documentation of the testing process, equipment used, and any deviations noted alongside proposed corrective actions. Building a repository of historical data also empowers future predictions and decision-making. In product terms, contemporary advancements in capacitance and tan delta testers have revolutionized their convenience and utility. Modern devices are incredibly portable, allowing for on-site diagnostics without needing extensive testing setups. They integrate seamlessly with software platforms for data management, thus providing immediate feedback and comprehensive analytics. This evolution not only enhances the scope of diagnostics but also optimizes time and resources, reflecting the industry's trend towards more efficient, user-friendly practices. Ultimately, proficiency in capacitance and tan delta measurements is indispensable for those invested in the electrical equipment domain. It offers a pathway to enhance system reliability, minimize downtime, and ensure the safety of operations. For manufacturers and electrical engineers, staying versed with cutting-edge testing methodologies and evolving industry standards is essential to uphold quality and performance benchmarks, reinforcing their reputation in an increasingly competitive market.

As authoritative figures in electrical testing domains stress, adherence to standards such as those set by IEEE and IEC is essential. These standards ensure uniformity in testing methods and results, promoting trust and credibility in the findings. For instance, critical values and acceptable ranges for capacitance and tan delta differ across equipment types and industry applications, as specified in these guidelines. Establishing trustworthiness involves transparent reporting and analysis of measurement outcomes. For those in asset management, providing clear reports that break down complex data into actionable insights is crucial. This includes detailed documentation of the testing process, equipment used, and any deviations noted alongside proposed corrective actions. Building a repository of historical data also empowers future predictions and decision-making. In product terms, contemporary advancements in capacitance and tan delta testers have revolutionized their convenience and utility. Modern devices are incredibly portable, allowing for on-site diagnostics without needing extensive testing setups. They integrate seamlessly with software platforms for data management, thus providing immediate feedback and comprehensive analytics. This evolution not only enhances the scope of diagnostics but also optimizes time and resources, reflecting the industry's trend towards more efficient, user-friendly practices. Ultimately, proficiency in capacitance and tan delta measurements is indispensable for those invested in the electrical equipment domain. It offers a pathway to enhance system reliability, minimize downtime, and ensure the safety of operations. For manufacturers and electrical engineers, staying versed with cutting-edge testing methodologies and evolving industry standards is essential to uphold quality and performance benchmarks, reinforcing their reputation in an increasingly competitive market.

Latest news

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024