TEL:

+86-0312-3189593

English

English

Telephone:0312-3189593

Email:sales@oil-tester.com

2 月 . 04, 2025 02:29

Back to list

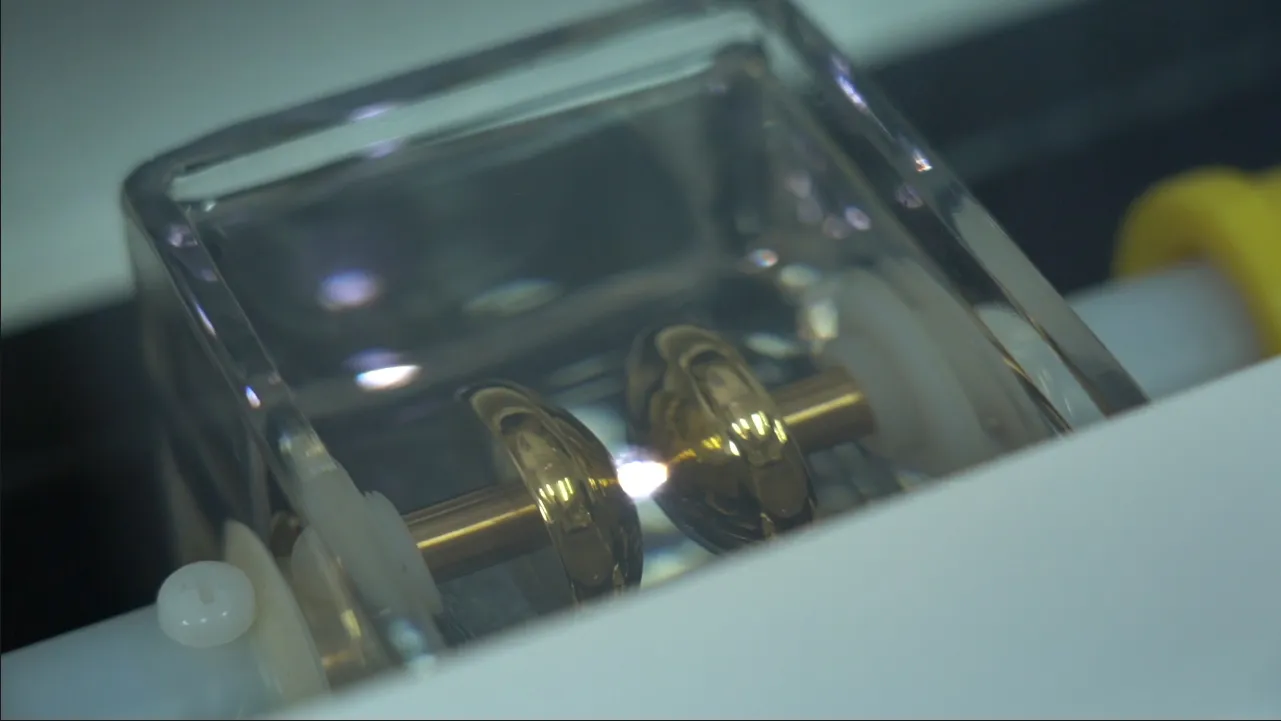

corrosive sulphur test in transformer oil

Corrosive sulphur in transformer oil has emerged as a critical issue for the reliability and longevity of electrical transformers. The phenomenon is notorious for its potential to cause serious damage by reacting with copper and forming conductive deposits, ultimately leading to transformer failures. Professionals working with electrical transformers demand a thorough understanding of how to test for corrosive sulphur and mitigate its effects.

Trustworthiness is significantly reinforced through transparent communication about the risks and solutions related to corrosive sulphur. For businesses in the power industry, choosing service providers with proven records and certified operations is critical. Trust is built when a provider offers not only testing services but also a comprehensive analysis, followed by actionable recommendations tailored to a client's specific operational context. Organizations maintaining significant capital investments in transformers often view proactive corrosive sulphur testing as a non-negotiable practice. Implementing these tests mitigates risks and enhances the lifespan of transformers, ultimately leading to substantial cost savings. By understanding the intricacies of corrosive sulphur and employing robust testing strategies, managers can make informed decisions and uphold the reliability of their power distribution systems. Through informed strategy and consistent application of expertise, authority, and trust, companies can effectively tackle the challenges posed by corrosive sulphur in transformer oils, demonstrating reliability and stability in their operations.

Trustworthiness is significantly reinforced through transparent communication about the risks and solutions related to corrosive sulphur. For businesses in the power industry, choosing service providers with proven records and certified operations is critical. Trust is built when a provider offers not only testing services but also a comprehensive analysis, followed by actionable recommendations tailored to a client's specific operational context. Organizations maintaining significant capital investments in transformers often view proactive corrosive sulphur testing as a non-negotiable practice. Implementing these tests mitigates risks and enhances the lifespan of transformers, ultimately leading to substantial cost savings. By understanding the intricacies of corrosive sulphur and employing robust testing strategies, managers can make informed decisions and uphold the reliability of their power distribution systems. Through informed strategy and consistent application of expertise, authority, and trust, companies can effectively tackle the challenges posed by corrosive sulphur in transformer oils, demonstrating reliability and stability in their operations.

Previous:

Next:

Latest news

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024