TEL:

+86-0312-3189593

English

English

Telephone:0312-3189593

Email:sales@oil-tester.com

1 月 . 31, 2025 04:08

Back to list

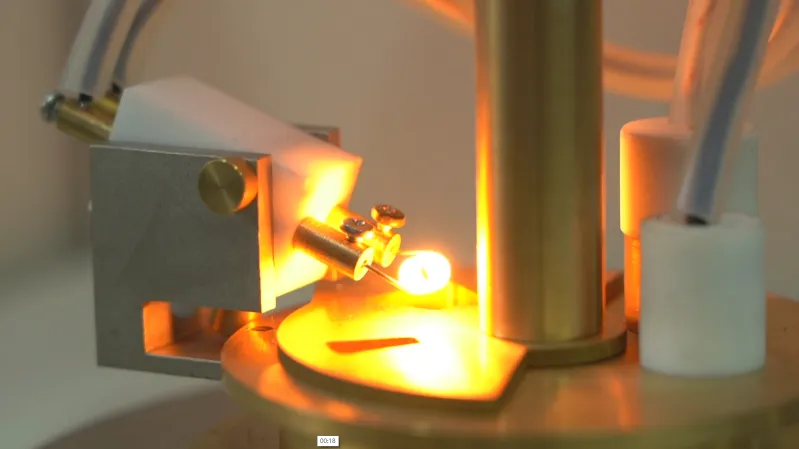

flash point measuring apparatus

The precision and reliability of flash point measuring apparatus significantly impact industries ranging from petrochemicals to consumer goods. In environments where safety is of utmost importance, understanding the nuances of such instruments is vital. This article delves into the expert insights and authoritative experiences that underline the utility, accuracy, and trustworthiness of flash point measuring devices.

The authority of a flash point measuring apparatus is not solely determined by its hardware or software, but also by the brand reputation and the after-sales support it offers. Companies like PAC and Eralytics are noted for their robust technical support and long-standing reputation in the industry. Sarah Nolan, a procurement specialist with over 15 years of experience, advises that choosing a device from a well-established manufacturer can drastically reduce downtime, as their support networks are often more reliable and responsive. From a safety perspective, flash point measurement is an essential protocol in the chemical and petroleum industries. Failing to accurately determine the flash point can lead to catastrophic hazards. Therefore, trust in these devices is non-negotiable, as it literally can be a life-or-death matter. Due to this, engineers and laboratory managers alike urge organizations to invest in cutting-edge equipment that complies with international safety standards. Real-world experiences also unveil the importance of periodic maintenance which enhances the apparatus's longevity and efficacy. Routine checks and timely repairs are vital, as neglect can lead to significant measurement errors which compromise safety. Maintenance not only augments the apparatus's lifespan but also ensures that the trustworthiness of the operation is upheld, cementing the company’s standing in adherence to safety protocols. In conclusion, the choice and use of a flash point measuring apparatus is an art and science necessitating expertise, authority, and trustworthiness. Industries lean heavily on manufacturers who ensure these parameters through rigorous quality checks, comprehensive training programs, and reliable customer support. For any prospective buyer or user, understanding these dynamics can lead to informed decisions and enhanced safety outcomes. The fusion of technical precision, adaptability, and professional expertise ultimately defines the remarkable efficacy and reliability of modern flash point measuring tools.

The authority of a flash point measuring apparatus is not solely determined by its hardware or software, but also by the brand reputation and the after-sales support it offers. Companies like PAC and Eralytics are noted for their robust technical support and long-standing reputation in the industry. Sarah Nolan, a procurement specialist with over 15 years of experience, advises that choosing a device from a well-established manufacturer can drastically reduce downtime, as their support networks are often more reliable and responsive. From a safety perspective, flash point measurement is an essential protocol in the chemical and petroleum industries. Failing to accurately determine the flash point can lead to catastrophic hazards. Therefore, trust in these devices is non-negotiable, as it literally can be a life-or-death matter. Due to this, engineers and laboratory managers alike urge organizations to invest in cutting-edge equipment that complies with international safety standards. Real-world experiences also unveil the importance of periodic maintenance which enhances the apparatus's longevity and efficacy. Routine checks and timely repairs are vital, as neglect can lead to significant measurement errors which compromise safety. Maintenance not only augments the apparatus's lifespan but also ensures that the trustworthiness of the operation is upheld, cementing the company’s standing in adherence to safety protocols. In conclusion, the choice and use of a flash point measuring apparatus is an art and science necessitating expertise, authority, and trustworthiness. Industries lean heavily on manufacturers who ensure these parameters through rigorous quality checks, comprehensive training programs, and reliable customer support. For any prospective buyer or user, understanding these dynamics can lead to informed decisions and enhanced safety outcomes. The fusion of technical precision, adaptability, and professional expertise ultimately defines the remarkable efficacy and reliability of modern flash point measuring tools.

Latest news

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024