TEL:

+86-0312-3189593

English

English

Telephone:0312-3189593

Email:sales@oil-tester.com

1 月 . 26, 2025 01:34

Back to list

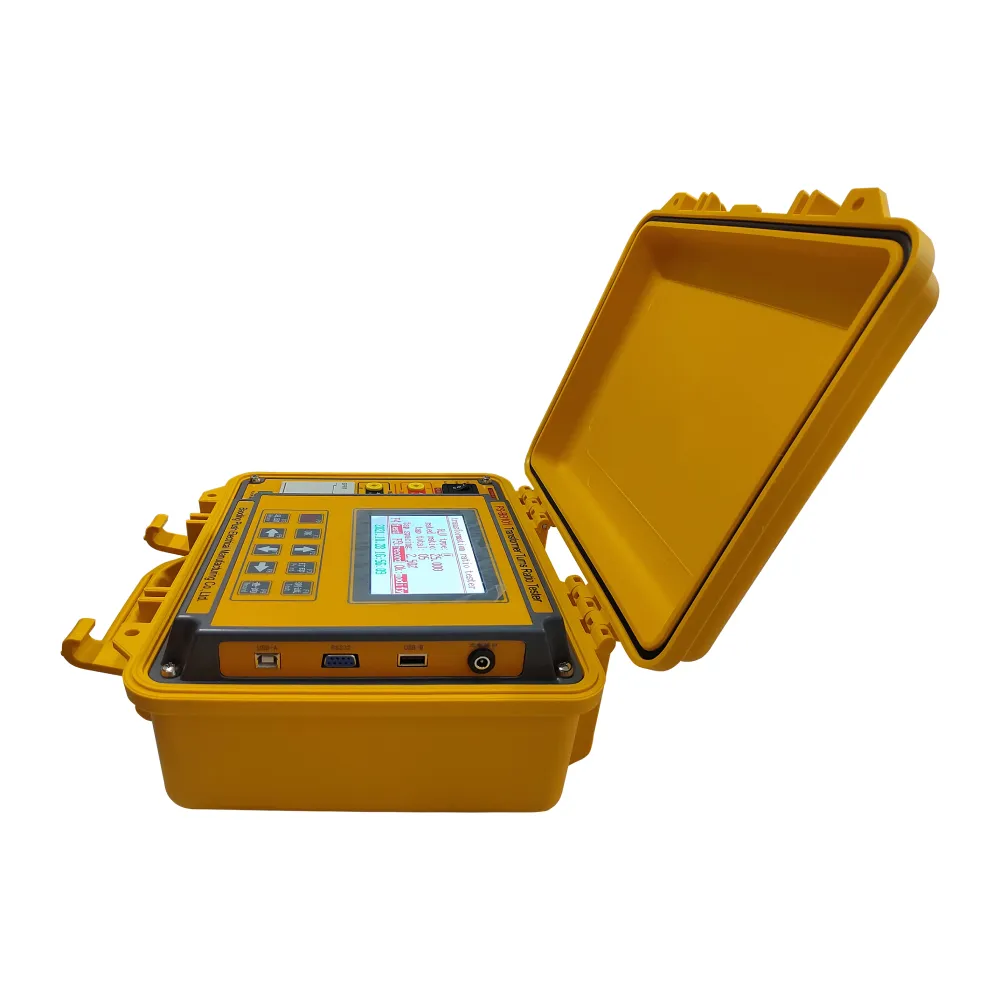

PS-2000A Insulating Oil Dielectric Loss And Volume Resistivity Tester

Gas Chromatography (GC) and Gas Chromatography-Mass Spectrometry (GC-MS) have emerged as indispensable techniques in analytical chemistry, offering unparalleled precision and reliability across industries. These methods are pivotal for the separation, identification, and quantification of complex chemical mixtures, playing a crucial role in fields ranging from pharmaceuticals to environmental science.

The authoritativeness of GC and GC-MS is demonstrated by their widespread adoption across rigorous scientific disciplines. Accreditation bodies and industry standards continuously reference these techniques, underscoring their reliability and credibility. Advanced training and certification programs further validate the expertise required to operate GC and GC-MS instrumentation proficiently, ensuring that results generated are both trustworthy and reproducible. Emphasizing trustworthiness, manufacturers of GC and GC-MS instruments invest significantly in research and development to enhance the sensitivity, user-friendliness, and durability of their products. Continuous innovations, such as temperature-programmed techniques and automated sample preparation, streamline the analytical process, reducing human error and increasing throughput. Real-world experiences from professionals highlight the versatility of GC and GC-MS. Analytical chemists consistently report success in identifying unknown compounds in complex matrices, attesting to the instruments’ precision. Troubleshooting techniques shared within the community, such as calibration checks and maintenance best practices, contribute to the collective knowledge, ensuring optimal performance and data integrity. Ultimately, the sophistication of GC and GC-MS systems is matched by their adaptability. Whether in a compact benchtop model for academic labs or an advanced configuration for industrial analysis, their applications are vast and varied. With continual advancements and shared expertise among users, GC and GC-MS remain at the forefront of chemical analysis, driving progress and innovation within scientific research and industry practices worldwide.

The authoritativeness of GC and GC-MS is demonstrated by their widespread adoption across rigorous scientific disciplines. Accreditation bodies and industry standards continuously reference these techniques, underscoring their reliability and credibility. Advanced training and certification programs further validate the expertise required to operate GC and GC-MS instrumentation proficiently, ensuring that results generated are both trustworthy and reproducible. Emphasizing trustworthiness, manufacturers of GC and GC-MS instruments invest significantly in research and development to enhance the sensitivity, user-friendliness, and durability of their products. Continuous innovations, such as temperature-programmed techniques and automated sample preparation, streamline the analytical process, reducing human error and increasing throughput. Real-world experiences from professionals highlight the versatility of GC and GC-MS. Analytical chemists consistently report success in identifying unknown compounds in complex matrices, attesting to the instruments’ precision. Troubleshooting techniques shared within the community, such as calibration checks and maintenance best practices, contribute to the collective knowledge, ensuring optimal performance and data integrity. Ultimately, the sophistication of GC and GC-MS systems is matched by their adaptability. Whether in a compact benchtop model for academic labs or an advanced configuration for industrial analysis, their applications are vast and varied. With continual advancements and shared expertise among users, GC and GC-MS remain at the forefront of chemical analysis, driving progress and innovation within scientific research and industry practices worldwide.

Latest news

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024