TEL:

+86-0312-3189593

English

English

Telephone:0312-3189593

Email:sales@oil-tester.com

3 月 . 06, 2025 10:58

Back to list

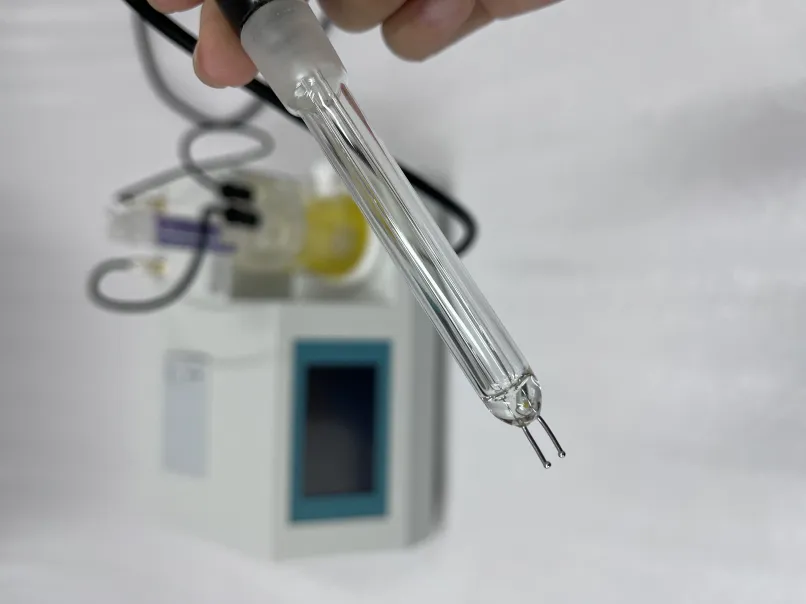

inductor tester

Inductor testing is a crucial aspect of ensuring the reliability and efficiency of electronic devices. A sophisticated inductor tester can save engineers, hobbyists, and product developers time while ensuring that inductors meet the necessary specifications. When it comes to choosing the right inductor tester, understanding key features and fostering trust in its capabilities is paramount.

Inductor testers must be accompanied by a robust set of safety features to ensure user and device protection. Testers should incorporate overload protection, which guards against damage from excessive currents or voltages during testing. This protection is fundamental in maintaining the tester’s longevity and reliability, thereby fostering trust in the device’s operational safety. Documentation, such as a comprehensive manual and access to customer support, enhances a tester's trustworthiness. Manufacturers who provide detailed guides and responsive service enable users to maximize the tester’s potential while minimizing downtime due to operational issues or misunderstandings. When it comes to the expertise reflected in these devices, engineers and technicians should look for testers with a wide measurement range. Some advanced models can test inductors ranging from a few microhenries to several henries, accommodating a broad spectrum of applications. Additionally, testers that offer a frequency selection for testing provide more insight into how the inductor behaves across different conditions, invaluable for applications requiring high-frequency performance assurance. The authority of a particular inductor tester brand or model often comes from its adoption in critical industries and its positive reception in professional reviews. Testers used by leading companies or in stringent applications are generally more reliable, as they have been vetted under demanding circumstances. Testimonials and peer-reviewed evaluations contribute to establishing a brand’s reputation in the market. Ultimately, the trustworthiness of an inductor tester is bolstered by warranties and service guarantees. Brands that back their products with service plans or extended warranties signal confidence in their product’s durability and support, providing users peace of mind. In conclusion, choosing the right inductor tester involves evaluating its precision, ease of use, connectivity, portability, safety features, documentation, expertise, authority, and trustworthiness. A well-informed decision will ensure that the selected tester meets the necessary requirements for accurate and reliable inductor analysis, essential for maintaining high-performance standards in any electronic application. By focusing on these aspects, users can ensure that their projects—from small-scale prototypes to large-scale production—benefit from optimized component performance and longevity.

Inductor testers must be accompanied by a robust set of safety features to ensure user and device protection. Testers should incorporate overload protection, which guards against damage from excessive currents or voltages during testing. This protection is fundamental in maintaining the tester’s longevity and reliability, thereby fostering trust in the device’s operational safety. Documentation, such as a comprehensive manual and access to customer support, enhances a tester's trustworthiness. Manufacturers who provide detailed guides and responsive service enable users to maximize the tester’s potential while minimizing downtime due to operational issues or misunderstandings. When it comes to the expertise reflected in these devices, engineers and technicians should look for testers with a wide measurement range. Some advanced models can test inductors ranging from a few microhenries to several henries, accommodating a broad spectrum of applications. Additionally, testers that offer a frequency selection for testing provide more insight into how the inductor behaves across different conditions, invaluable for applications requiring high-frequency performance assurance. The authority of a particular inductor tester brand or model often comes from its adoption in critical industries and its positive reception in professional reviews. Testers used by leading companies or in stringent applications are generally more reliable, as they have been vetted under demanding circumstances. Testimonials and peer-reviewed evaluations contribute to establishing a brand’s reputation in the market. Ultimately, the trustworthiness of an inductor tester is bolstered by warranties and service guarantees. Brands that back their products with service plans or extended warranties signal confidence in their product’s durability and support, providing users peace of mind. In conclusion, choosing the right inductor tester involves evaluating its precision, ease of use, connectivity, portability, safety features, documentation, expertise, authority, and trustworthiness. A well-informed decision will ensure that the selected tester meets the necessary requirements for accurate and reliable inductor analysis, essential for maintaining high-performance standards in any electronic application. By focusing on these aspects, users can ensure that their projects—from small-scale prototypes to large-scale production—benefit from optimized component performance and longevity.

Previous:

Latest news

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024