TEL:

+86-0312-3189593

English

English

Telephone:0312-3189593

Email:sales@oil-tester.com

1 月 . 21, 2025 03:02

Back to list

oil bdv test of transformer

Oil Breakdown Voltage (BDV) testing of transformers plays a critical role in maintaining the reliability and longevity of these electrical devices. Transformers are fundamental components in electrical power systems, and maintaining their efficiency is paramount for delivering uninterrupted electricity service. This article delves into the significance of the oil BDV test, exploring its importance, methodology, and impact on transformer functionality.

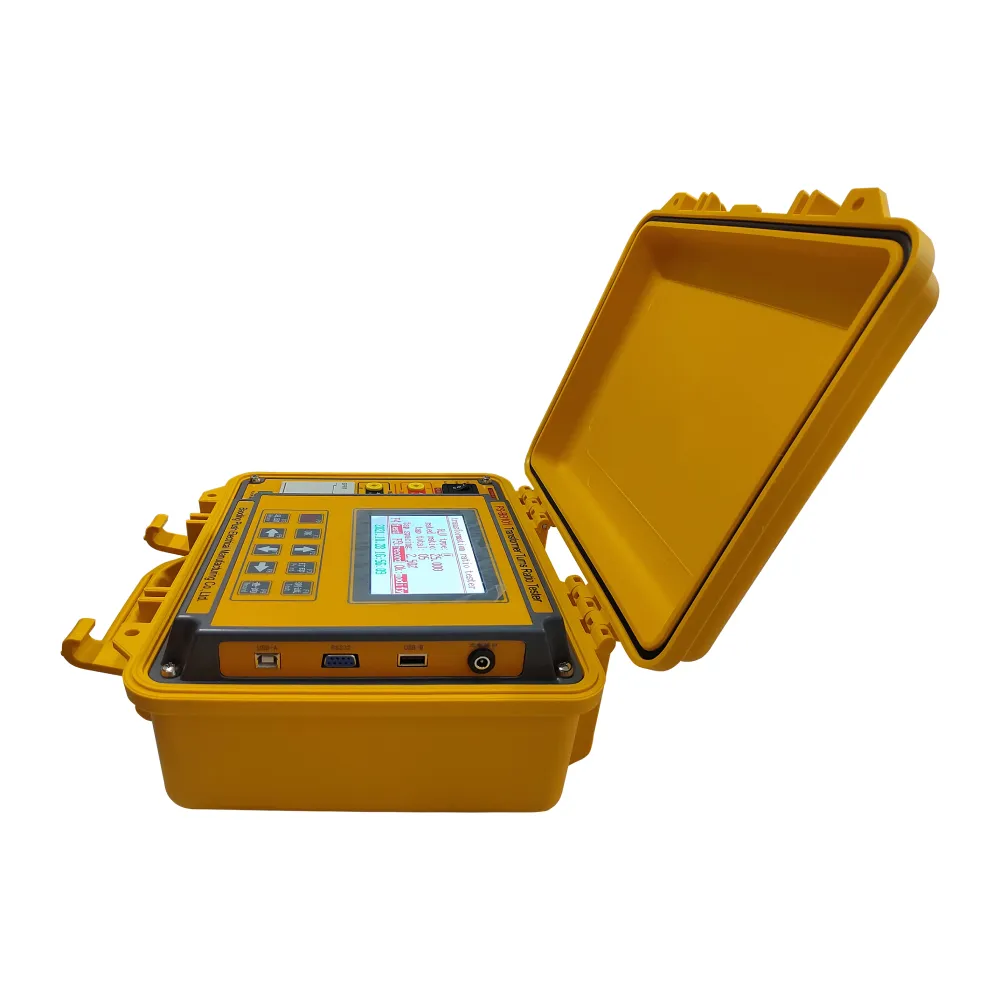

The BDV test not only provides insights into the oil’s condition but also indirectly assesses the transformer’s overall health. Regular monitoring can highlight issues such as moisture ingress, paper insulation degradation, or oil contamination, allowing for timely interventions. By preventing catastrophic failures, BDV testing contributes significantly to extended transformer life and reduced maintenance costs. Incorporating modern technology in BDV testing enhances its efficacy. Some advanced testing kits offer automated procedures and real-time data analysis, making it easier for engineers to make informed decisions. The integration of data management systems allows for the tracking of historical data, identifying patterns, and predicting potential failures. Transformers, being integral to power distribution networks, demand a high degree of reliability. The BDV test is an essential tool in ensuring that the insulating oil meets safety and performance standards. For operators and maintenance engineers, understanding the nuances of BDV testing and its implications is crucial for maintaining operational excellence. Investing in expert training and using high-quality testing equipment can elevate the reliability of BDV testing. Practical experience combined with theoretical knowledge ensures a deeper understanding of test results, leading to more effective maintenance and management strategies. In conclusion, the oil BDV test of transformers is a vital aspect of electrical maintenance that safeguards against transformer failure. Its ability to detect insulation deterioration early makes it an indispensable tool for electrical utilities and industrial operations. By prioritizing BDV testing and following best practices, stakeholders can enhance transformer reliability, optimize performance, and ensure efficient power distribution.

The BDV test not only provides insights into the oil’s condition but also indirectly assesses the transformer’s overall health. Regular monitoring can highlight issues such as moisture ingress, paper insulation degradation, or oil contamination, allowing for timely interventions. By preventing catastrophic failures, BDV testing contributes significantly to extended transformer life and reduced maintenance costs. Incorporating modern technology in BDV testing enhances its efficacy. Some advanced testing kits offer automated procedures and real-time data analysis, making it easier for engineers to make informed decisions. The integration of data management systems allows for the tracking of historical data, identifying patterns, and predicting potential failures. Transformers, being integral to power distribution networks, demand a high degree of reliability. The BDV test is an essential tool in ensuring that the insulating oil meets safety and performance standards. For operators and maintenance engineers, understanding the nuances of BDV testing and its implications is crucial for maintaining operational excellence. Investing in expert training and using high-quality testing equipment can elevate the reliability of BDV testing. Practical experience combined with theoretical knowledge ensures a deeper understanding of test results, leading to more effective maintenance and management strategies. In conclusion, the oil BDV test of transformers is a vital aspect of electrical maintenance that safeguards against transformer failure. Its ability to detect insulation deterioration early makes it an indispensable tool for electrical utilities and industrial operations. By prioritizing BDV testing and following best practices, stakeholders can enhance transformer reliability, optimize performance, and ensure efficient power distribution.

Previous:

Latest news

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024