TEL:

+86-0312-3189593

English

English

Telephone:0312-3189593

Email:sales@oil-tester.com

1 月 . 21, 2025 03:24

Back to list

transformer oil bdv test kit

The transformer oil BDV (Breakdown Voltage) test kit is a crucial tool in maintaining the efficiency and safety of electrical transformers. Transformer oil serves as both an insulating material and a coolant in transformers. Its ability to insulate effectively is essential for preventing electrical discharges that can lead to equipment failure. Therefore, regular testing using a BDV test kit ensures that the transformer oil retains its insulating properties.

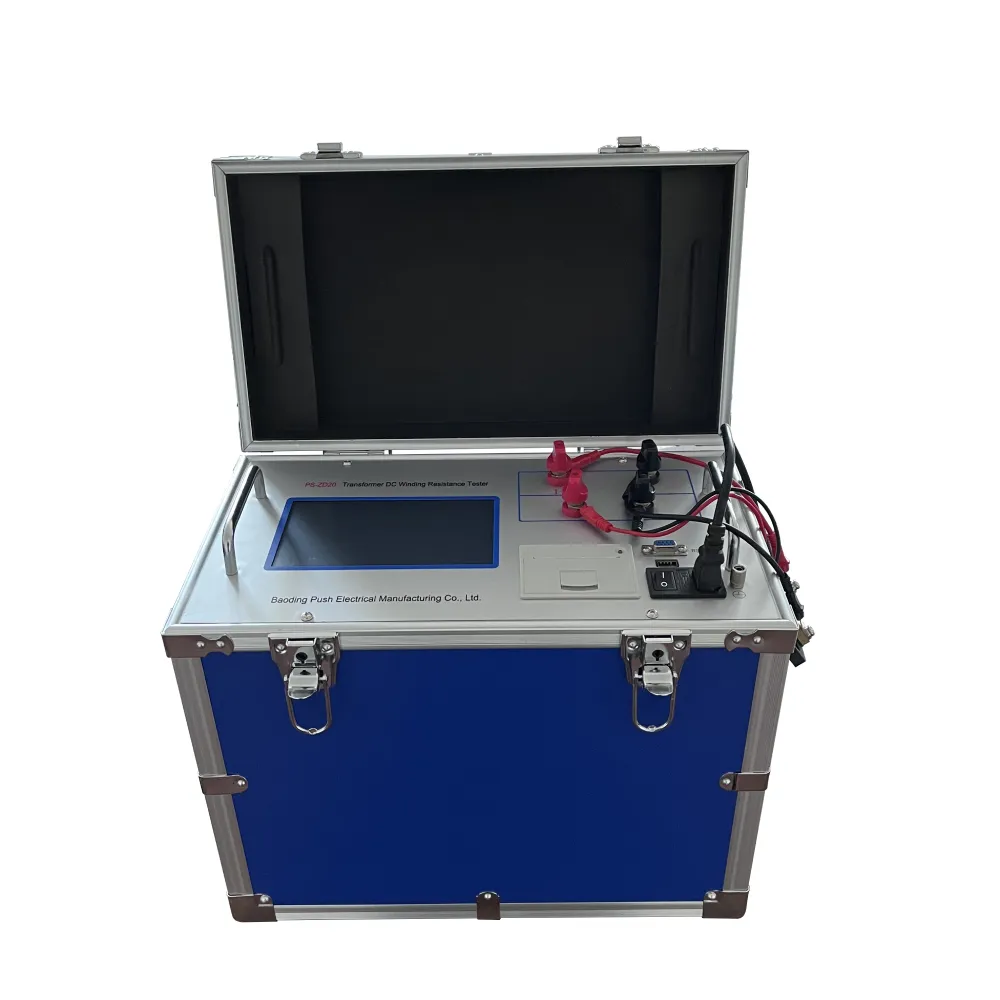

When evaluating BDV test kits, robustness and portability are significant factors. Generally, test kits that are designed for field use should be compact, lightweight, and resilient against harsh environmental conditions. A rugged design ensures that the kit can withstand the rigors of frequent transport and testing in diverse locations, which is particularly important for utility companies and service providers that manage multiple sites. From a professional perspective, the value of a BDV test kit also lies in its ability to provide data that can be seamlessly integrated into a company’s existing asset management systems. Data connectivity through USB or wireless systems ensures that test results can be easily archived and analyzed over time, offering a valuable resource for predictive maintenance strategies. Trust in a manufacturer’s reputation is equally crucial. Purchasing a test kit from a well-established brand known for its quality products provides additional assurance in reliability and long-term support. Firms that offer comprehensive technical support, training, and after-sales service empower their clients to maximize the benefits from their equipment, fortifying trust between the manufacturer and the user. Selecting the right transformer oil BDV test kit requires an understanding of not just current industry standards but also of emerging trends and innovations. By staying informed about the latest developments in BDV testing, maintenance teams can better anticipate and adapt to future needs, ensuring their transformers operate optimally, thus safeguarding their investment and upholding energy delivery reliability. In conclusion, a transformer oil BDV test kit is an essential investment for any entity involved in maintaining high-voltage transformers. By choosing a kit that exemplifies precision, ease of use, robustness, and comprehensive functionality, operators ensure that their transformers’ operational integrity is maintained. Moreover, partnering with a reputable manufacturer provides added advantages in terms of support and innovation, thus reinforcing the test kit’s role as a key component in effective transformer maintenance strategies. Through informed decisions and strategic investments in technology, organizations can not only meet current demands but also position themselves for future challenges.

When evaluating BDV test kits, robustness and portability are significant factors. Generally, test kits that are designed for field use should be compact, lightweight, and resilient against harsh environmental conditions. A rugged design ensures that the kit can withstand the rigors of frequent transport and testing in diverse locations, which is particularly important for utility companies and service providers that manage multiple sites. From a professional perspective, the value of a BDV test kit also lies in its ability to provide data that can be seamlessly integrated into a company’s existing asset management systems. Data connectivity through USB or wireless systems ensures that test results can be easily archived and analyzed over time, offering a valuable resource for predictive maintenance strategies. Trust in a manufacturer’s reputation is equally crucial. Purchasing a test kit from a well-established brand known for its quality products provides additional assurance in reliability and long-term support. Firms that offer comprehensive technical support, training, and after-sales service empower their clients to maximize the benefits from their equipment, fortifying trust between the manufacturer and the user. Selecting the right transformer oil BDV test kit requires an understanding of not just current industry standards but also of emerging trends and innovations. By staying informed about the latest developments in BDV testing, maintenance teams can better anticipate and adapt to future needs, ensuring their transformers operate optimally, thus safeguarding their investment and upholding energy delivery reliability. In conclusion, a transformer oil BDV test kit is an essential investment for any entity involved in maintaining high-voltage transformers. By choosing a kit that exemplifies precision, ease of use, robustness, and comprehensive functionality, operators ensure that their transformers’ operational integrity is maintained. Moreover, partnering with a reputable manufacturer provides added advantages in terms of support and innovation, thus reinforcing the test kit’s role as a key component in effective transformer maintenance strategies. Through informed decisions and strategic investments in technology, organizations can not only meet current demands but also position themselves for future challenges.

Latest news

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024