TEL:

+86-0312-3189593

English

English

Telephone:0312-3189593

Email:sales@oil-tester.com

2 月 . 13, 2025 12:16

Back to list

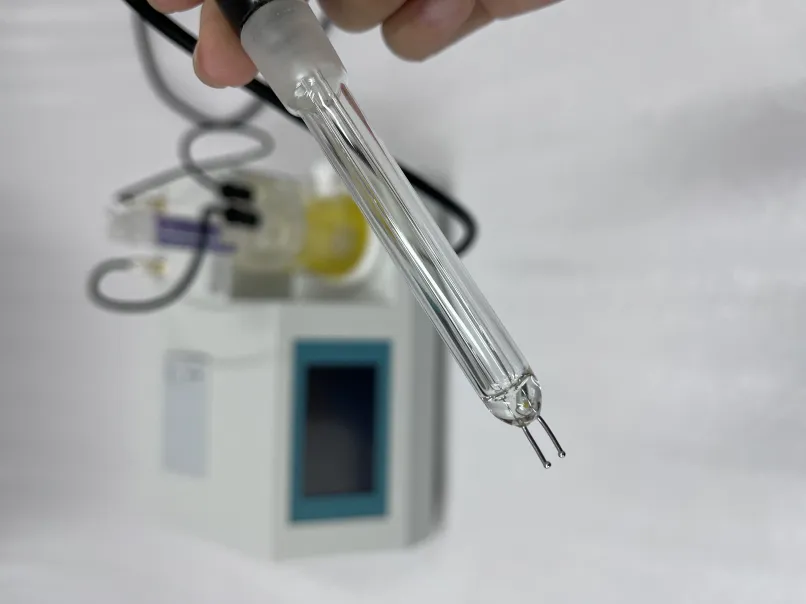

power transformer insulation resistance test

Understanding the intricacies of power transformer insulation resistance testing is vital for the maintenance and longevity of electrical systems. Ensuring the optimal performance of transformers is critical, given their pivotal role in energy transmission and distribution. This article delves into the essential elements of this process, drawing from firsthand experience, industry expertise, authoritative practices, and trustworthy methodologies to provide unmatched insights into this critical electrical maintenance procedure.

Authority in this domain is established by adhering to state-of-the-art testing procedures and industry standards, such as those set by the IEEE (Institute of Electrical and Electronics Engineers). For instance, IEEE standards emphasize the importance of conducting insulation resistance tests as part of routine maintenance schedules. Moreover, maintaining detailed records of insulation resistance readings over time establishes a baseline that can reveal trends indicative of insulation health—the cornerstone of predictive maintenance strategies. Trustworthiness in power transformer maintenance is solidified when testing results are meticulously documented and analyzed. Comparing current test results with historical data allows maintenance professionals to predict potential failure points before they develop into critical issues. In practice, a sudden drop in insulation resistance values compared to previous readings often signals insulation breakdown, necessitating immediate intervention. This data-driven approach not only enhances equipment reliability but also positions service providers as reliable partners in asset management. Incorporating these comprehensive methodologies leads to effective insulation resistance testing, contributing to enhanced transformer performance and longevity. Discussing case studies where insulation resistance testing preemptively identified potential failures offers valuable lessons learned, further substantiating the effectiveness of these practices. By actively sharing knowledge and success stories within the industry, professionals elevate the overall standard of electrical maintenance. Ultimately, the goal is to extend the operational life of power transformers, minimizing costly repairs and outages. Emphasizing experience, leveraging advanced expertise, upholding authoritative standards, and ensuring trustworthiness in every step of the insulation resistance testing process not only optimize transformer performance but also safeguard the integrity of our critical electrical infrastructures.

Authority in this domain is established by adhering to state-of-the-art testing procedures and industry standards, such as those set by the IEEE (Institute of Electrical and Electronics Engineers). For instance, IEEE standards emphasize the importance of conducting insulation resistance tests as part of routine maintenance schedules. Moreover, maintaining detailed records of insulation resistance readings over time establishes a baseline that can reveal trends indicative of insulation health—the cornerstone of predictive maintenance strategies. Trustworthiness in power transformer maintenance is solidified when testing results are meticulously documented and analyzed. Comparing current test results with historical data allows maintenance professionals to predict potential failure points before they develop into critical issues. In practice, a sudden drop in insulation resistance values compared to previous readings often signals insulation breakdown, necessitating immediate intervention. This data-driven approach not only enhances equipment reliability but also positions service providers as reliable partners in asset management. Incorporating these comprehensive methodologies leads to effective insulation resistance testing, contributing to enhanced transformer performance and longevity. Discussing case studies where insulation resistance testing preemptively identified potential failures offers valuable lessons learned, further substantiating the effectiveness of these practices. By actively sharing knowledge and success stories within the industry, professionals elevate the overall standard of electrical maintenance. Ultimately, the goal is to extend the operational life of power transformers, minimizing costly repairs and outages. Emphasizing experience, leveraging advanced expertise, upholding authoritative standards, and ensuring trustworthiness in every step of the insulation resistance testing process not only optimize transformer performance but also safeguard the integrity of our critical electrical infrastructures.

Previous:

Latest news

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024