English

English

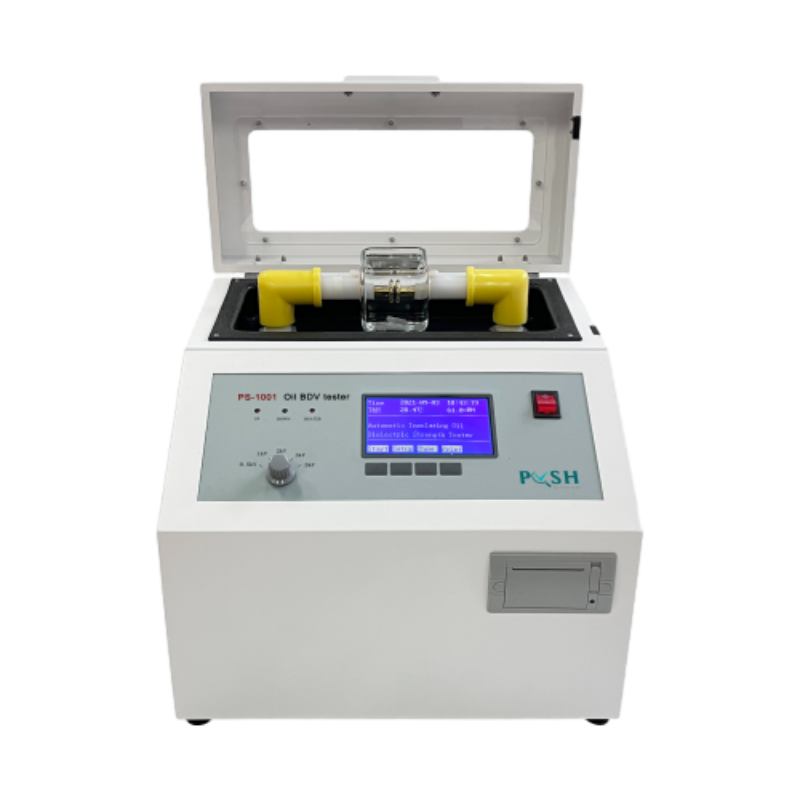

Tan Delta Testing Techniques for Assessing Power Transformer Insulation Health and Performance

Tan Delta Testing of Power Transformers

Tan delta testing, also known as power factor testing, is a critical diagnostic procedure used to assess the insulation condition of power transformers. The method is essential for ensuring the reliability and longevity of transformers, as insulation degradation can lead to catastrophic failures and costly outages in power distribution systems. This article explores the principles, procedures, and significance of tan delta testing in the context of power transformers.

Understanding Tan Delta

The term tan delta refers to the tangent of the loss angle (δ) formed between the current flowing through the insulation and the voltage across it. This loss angle correlates to the dielectric properties of the insulation material. A lower value of tan delta indicates healthier insulation, while a higher value suggests degraded insulation quality. Tan delta is expressed mathematically as

\[ \tan(\delta) = \frac{I_d}{I_c} \]

where \(I_d\) is the destructive current and \(I_c\) is the capacitive current. The tan delta test is performed at various frequencies and temperatures to provide a comprehensive view of the insulation condition.

The Importance of Tan Delta Testing

1. Early Detection of Insulation Degradation Regular tan delta testing helps to identify insulation issues before they lead to significant failures. By monitoring the tan delta values over time, engineers can observe trends and detect any signs of deterioration.

2. Improving Transformer Reliability Power transformers are crucial components in electrical grids, and their failure can result in severe economic consequences and service interruptions. Tan delta testing enhances overall system reliability by ensuring that potential problem areas are identified and addressed well in advance.

3. Assessment of Aging Transformers As transformers age, their insulation systems can deteriorate. Tan delta testing enables utilities to determine the remaining useful life of these aging transformers and make informed decisions regarding maintenance, refurbishment, or replacement.

tan delta testing of power transformer pdf

The Testing Process

The tan delta testing procedure involves several steps

1. Preparation Before testing, ensure that the transformer is isolated from the grid and properly grounded. Safety measures must be taken to protect personnel and equipment.

2. Connection Connect the testing apparatus to the transformer’s bushings or terminals. Modern test sets can measure voltage, current, and phase angles, providing real-time tan delta values.

3. Application of Voltage A sinusoidal voltage is applied to the transformer’s insulation system. The tan delta tester measures the phase relationship between the current and voltage, allowing it to compute the tan delta.

4. Data Analysis Once the measurements are obtained, they are analyzed to determine the insulation condition. Comparisons with baseline measurements taken during previous tests can reveal trends and indicate potential issues.

5. Reporting The results of the tan delta test are compiled into a report, highlighting key findings, recommendations, and any necessary follow-up actions.

Conclusion

Tan delta testing is an indispensable tool in the maintenance and management of power transformers. By providing valuable insights into the insulation condition, this testing method enables utilities to mitigate risks, optimize maintenance schedules, and prolong the operational life of their assets. As the power distribution network becomes increasingly complex, the role of diagnostic testing methods like tan delta will be vital for ensuring the safety and efficiency of electrical systems. Adopting advanced testing practices ensures that transformers continue to perform reliably in an ever-evolving energy landscape. Thus, the proactive use of tan delta testing is not merely a preventive measure; it is a strategic approach to safeguarding our power infrastructure for the future.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024