English

English

Transformer Oil Analysis Experiment for Performance and Reliability Assessment

Transformer Oil Testing An Essential Experiment for Electrical Insulation

Transformer oil, an essential component in electrical engineering, serves primarily as an insulating and cooling medium for transformers. Its efficiency and reliability are paramount for the safe operation of power systems. To ensure the operational integrity of transformers, routine testing of transformer oil is crucial. This article discusses the importance of transformer oil testing experiments, the methods employed, and the implications of the results obtained.

Importance of Transformer Oil Testing

Transformer oil testing is necessary for several reasons. First and foremost, it plays a critical role in maintaining the safety and reliability of transformers, which are integral to power distribution. Insulation breakdown can lead to catastrophic failures, resulting in significant economic losses and safety hazards. Regular testing helps detect potential issues at an early stage, allowing for preventive measures to be implemented before failure occurs.

Additionally, transformer oil serves as a medium for heat dissipation. Over time, due to thermal stress and oxidation, the properties of the oil may degrade. Testing can reveal changes in viscosity, acidity, and dielectric strength, which are indicators of the oil’s ability to perform its cooling and insulating functions. By characterizing these properties, engineers can assess the oil’s condition and make informed decisions regarding maintenance or replacement.

Methods of Transformer Oil Testing

There are various methods used in transformer oil testing, each designed to evaluate specific properties of the oil

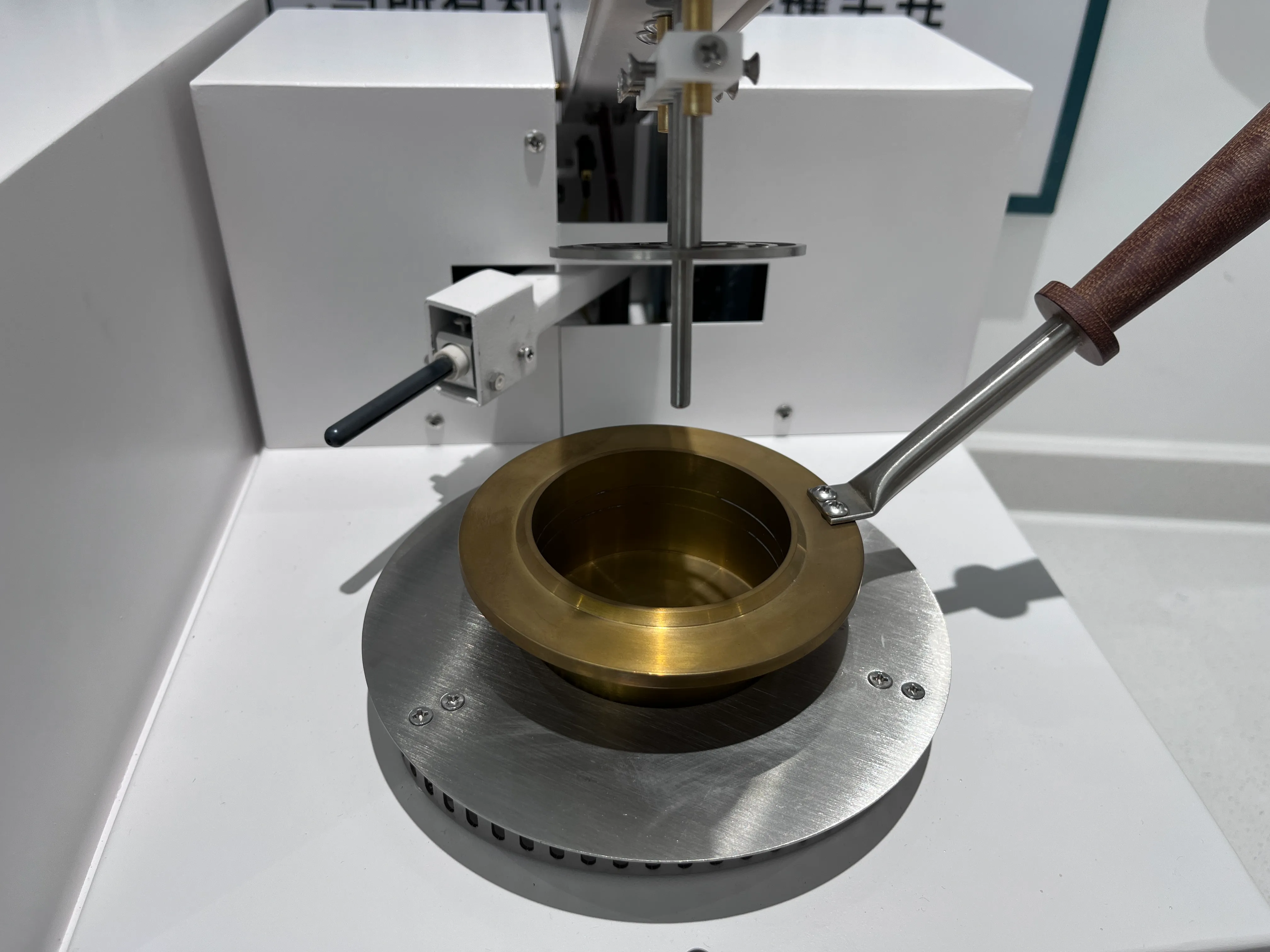

. Below are some of the most commonly employed techniques1. Dielectric Strength Testing This test measures the maximum voltage that the oil can withstand without breaking down. A high dielectric strength indicates good insulating properties. The test involves applying a voltage across a standardized gap and assessing the voltage level at which the oil fails.

2. Water Content Analysis Water in transformer oil can significantly affect its insulating properties. The presence of moisture can lead to electrical arcing and transformer failures. The Karl Fischer titration method is commonly used to quantify water content.

transformer oil testing experiment

3. Acidity and Neutralization Testing The acidity of transformer oil can increase due to oxidation over time. High acidity can corrode internal components of transformers. The neutralization number (NN) is measured to assess the oil’s condition, indicating the degree of degradation.

4. Furan Analysis This analytical technique involves examining the byproducts of insulation degradation, specifically furan derivatives found in paper insulation. High levels of furans indicate impending failure and can provide insights into the transformer’s overall health.

5. PCBs Testing Polychlorinated biphenyls (PCBs) were once commonly used in transformer oils but were banned due to their environmental impact. Testing for PCBs ensures compliance with regulations and safety standards.

Implications of Testing Results

The results obtained from transformer oil testing can significantly influence maintenance strategies and operational decisions. For instance, if dielectric strength is found to be below the acceptable threshold, it may indicate that the oil has absorbed moisture or undergone chemical degradation. Consequently, engineers may choose to replace the oil or perform additional maintenance to prevent a transformer failure.

Furthermore, consistent monitoring of transformer oil can inform predictive maintenance practices. By analyzing trends in the oil's properties over time, utility companies can plan for maintenance shutdowns during non-peak periods, thus avoiding unexpected outages and optimizing the lifecycle of their assets.

Conclusion

Transformer oil testing is a fundamental practice in ensuring the reliability and longevity of transformers. The various testing methods provide valuable insights into the condition of the oil and, by extension, the health of the transformer itself. In an age where technology and efficiency are paramount, regular transformer oil testing not only protects investments but also enhances the overall reliability of power distribution systems. As electrical infrastructure continues to evolve, the emphasis on rigorous testing protocols will only increase, emphasizing the need for ongoing research and development in the field of electrical insulation and protection technologies.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024