TEL:

+86-0312-3189593

English

English

Telephone:0312-3189593

Email:sales@oil-tester.com

2 月 . 15, 2025 11:08

Back to list

transformer core ground

Transformers are pivotal components in electrical systems, enabling the efficient transfer of electrical energy between circuits. An often-overlooked but crucial aspect of a transformer's operation is the proper grounding of its core. Transformer core grounding not only ensures safety but also enhances the performance and longevity of the equipment. Through experience and in-depth expertise, understanding the nuances of transformer core grounding becomes imperative for industry professionals, manufacturers, and maintenance teams.

Additionally, transformer manufacturers play a significant role in advancing grounding technologies. Leading manufacturers integrate state-of-the-art grounding designs, such as copper or aluminum grounding strips and bolts, that guarantee robust and lasting ground connections. As products of rigorous testing, these grounding components exhibit superior conductivity and corrosion resistance, ensuring performance even in harsh environmental conditions. This level of quality not only fosters trust among users but also establishes these manufacturers as pioneers in transformer safety. Real-world experience has further demonstrated that regular inspection and maintenance of transformer grounding systems is essential. Routine checks to ensure grounding connections are intact and free from corrosion or loosening bolster trust in the system’s reliability. Professionals experienced in this field recommend a bi-annual inspection schedule as part of preventive maintenance routines, coupled with thermography to detect possible hot spots indicating poor ground connections. Investments in proper grounding thus translate into tangible benefits enhanced safety for personnel, improved transformer efficiency, reduced equipment downtime, and ultimately, significant cost savings in both operational and maintenance expenditures. For facility managers and electrical engineers focusing on new installations or retrofits, understanding and implementing effective transformer core grounding are not merely regulatory obligations but prudent practices that safeguard infrastructure and optimize functionality. In conclusion, transformer core grounding stands as an essential practice rooted in experience, technical expertise, authoritative standards, and verified trustworthiness. While considered a specialized field within electrical engineering, mastery of transformer grounding assures stakeholders of operational excellence and safety, providing the crucial foundation on which electrical distribution depends. This overarching commitment to grounding excellence underscores its enduring importance in the modern electrical landscape, securing its place as a cornerstone of efficient and safe transformer operation.

Additionally, transformer manufacturers play a significant role in advancing grounding technologies. Leading manufacturers integrate state-of-the-art grounding designs, such as copper or aluminum grounding strips and bolts, that guarantee robust and lasting ground connections. As products of rigorous testing, these grounding components exhibit superior conductivity and corrosion resistance, ensuring performance even in harsh environmental conditions. This level of quality not only fosters trust among users but also establishes these manufacturers as pioneers in transformer safety. Real-world experience has further demonstrated that regular inspection and maintenance of transformer grounding systems is essential. Routine checks to ensure grounding connections are intact and free from corrosion or loosening bolster trust in the system’s reliability. Professionals experienced in this field recommend a bi-annual inspection schedule as part of preventive maintenance routines, coupled with thermography to detect possible hot spots indicating poor ground connections. Investments in proper grounding thus translate into tangible benefits enhanced safety for personnel, improved transformer efficiency, reduced equipment downtime, and ultimately, significant cost savings in both operational and maintenance expenditures. For facility managers and electrical engineers focusing on new installations or retrofits, understanding and implementing effective transformer core grounding are not merely regulatory obligations but prudent practices that safeguard infrastructure and optimize functionality. In conclusion, transformer core grounding stands as an essential practice rooted in experience, technical expertise, authoritative standards, and verified trustworthiness. While considered a specialized field within electrical engineering, mastery of transformer grounding assures stakeholders of operational excellence and safety, providing the crucial foundation on which electrical distribution depends. This overarching commitment to grounding excellence underscores its enduring importance in the modern electrical landscape, securing its place as a cornerstone of efficient and safe transformer operation.

Previous:

Latest news

-

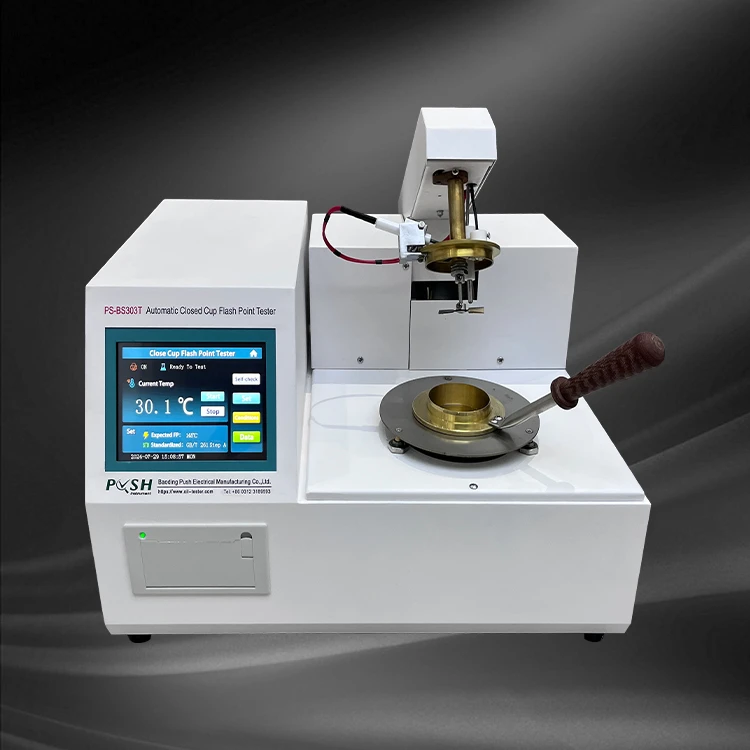

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024