TEL:

+86-0312-3189593

English

English

Telephone:0312-3189593

Email:sales@oil-tester.com

1 月 . 17, 2025 05:46

Back to list

PS-3045 High Voltage Insulation Resistance Tester

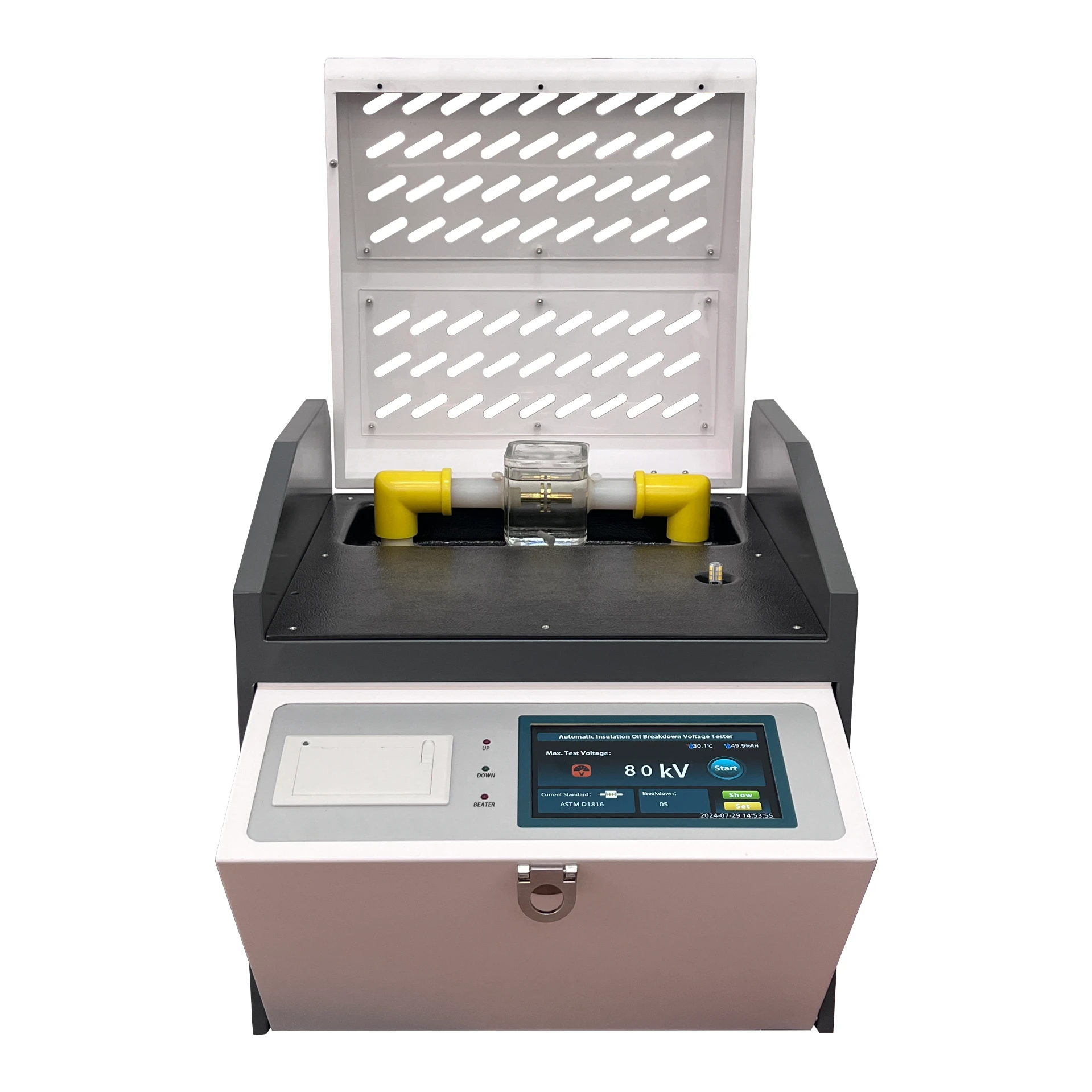

Oil testing is an indispensable process in numerous industries, ensuring machinery runs efficiently and safely. An oil tester is a pivotal tool in maintaining the health of equipment, providing insights into the quality, efficiency, and safety of oils used in applications ranging from automotive engines to industrial machinery. Understanding the nuances of oil testers can lead to improved performance, lower maintenance costs, and extended equipment lifespan.

Trustworthiness in oil testers is also built by their evolution and technological enhancement over the years. Modern testers often come integrated with software that not only records real-time data but also conducts comprehensive trend analysis. This digital integration aids in predictive maintenance, reducing the uncertainty that comes with manual interpretations. Reliable customer support and continuous updates to testing algorithms are additional aspects that contribute to a tester’s credibility. For decision-makers considering the investment in oil testers, focusing on brands with long-standing reputations in the industry can be highly beneficial. Feedback from existing users who highlight improvements in their operational efficiency provides valuable insights, aiding in forming a composite picture of a tester’s performance under diverse conditions. In conclusion, oil testers are not merely diagnostic tools. They are strategic assets in an organization's maintenance toolkit. Their ability to offer unparalleled insights into the condition of oils used in machinery translates into tangible business outcomes—lowering operational risks, enhancing machinery lifespan, and optimizing performance. By prioritizing the criteria of experience, expertise, authority, and trustworthiness in your selection process, you can ensure a strategic advantage in maintaining your machinery's efficiency and safety.

Trustworthiness in oil testers is also built by their evolution and technological enhancement over the years. Modern testers often come integrated with software that not only records real-time data but also conducts comprehensive trend analysis. This digital integration aids in predictive maintenance, reducing the uncertainty that comes with manual interpretations. Reliable customer support and continuous updates to testing algorithms are additional aspects that contribute to a tester’s credibility. For decision-makers considering the investment in oil testers, focusing on brands with long-standing reputations in the industry can be highly beneficial. Feedback from existing users who highlight improvements in their operational efficiency provides valuable insights, aiding in forming a composite picture of a tester’s performance under diverse conditions. In conclusion, oil testers are not merely diagnostic tools. They are strategic assets in an organization's maintenance toolkit. Their ability to offer unparalleled insights into the condition of oils used in machinery translates into tangible business outcomes—lowering operational risks, enhancing machinery lifespan, and optimizing performance. By prioritizing the criteria of experience, expertise, authority, and trustworthiness in your selection process, you can ensure a strategic advantage in maintaining your machinery's efficiency and safety.

Previous:

Latest news

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024