English

English

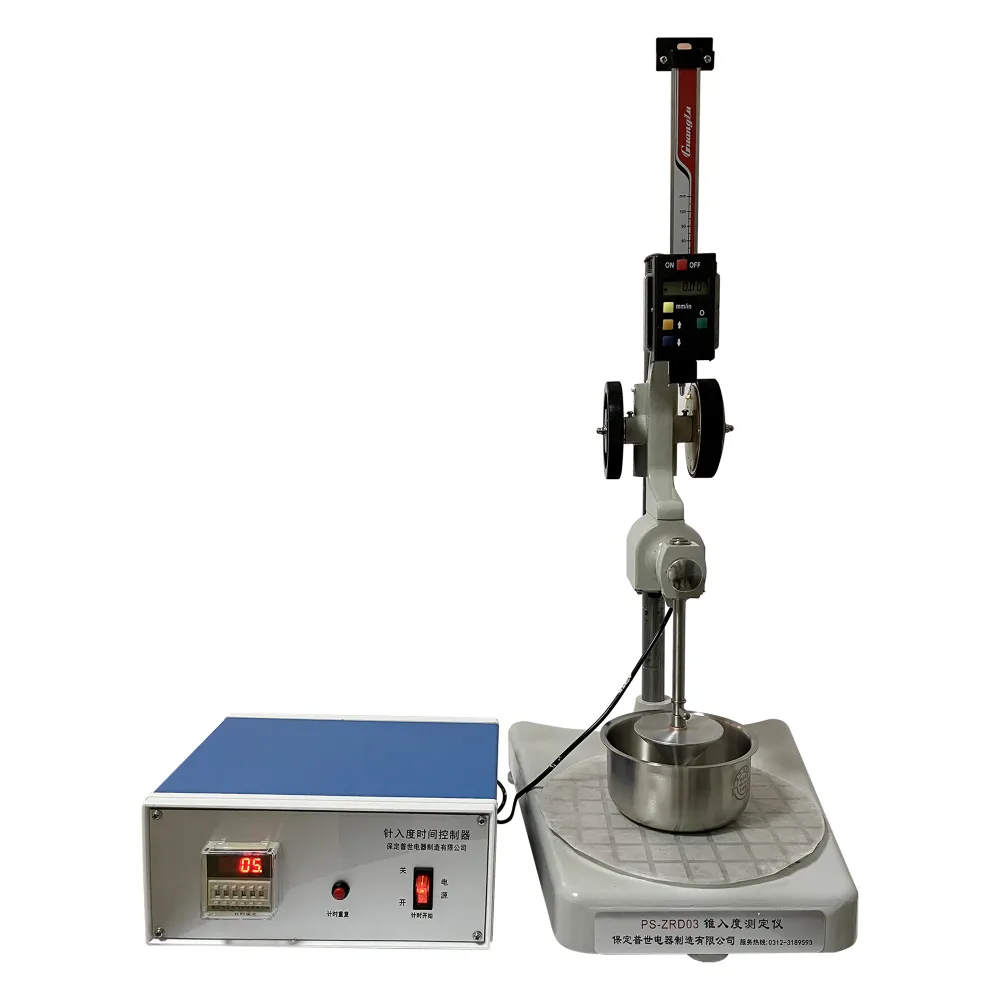

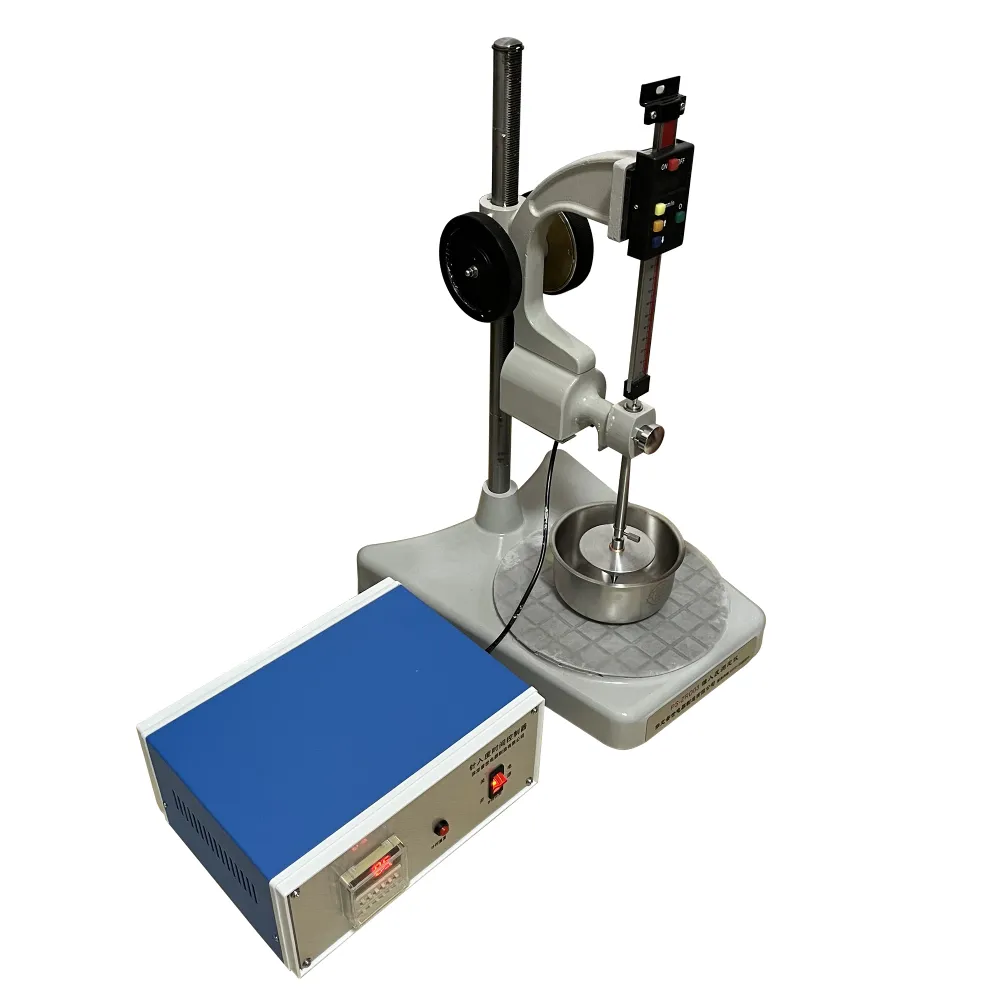

- The Cone Penetration Tester for lubricating grease, also known as a Grease Cone Penetrometer, is a specialized instrument used to measure the consistency or penetration depth of lubricating greases under standardized conditions. It assesses the degree of hardness or softness of grease, which is crucial for determining its suitability for various applications and ensuring optimal performance in machinery and equipment.

- Quality Control: Used by lubricant manufacturers and quality control laboratories to assess the consistency and performance of lubricating greases, ensuring compliance with industry standards and specifications.

- Product Development: Aids in the formulation and development of lubricating greases with desired consistency, viscosity, and penetration characteristics for specific applications and operating conditions.

- - Machinery Maintenance: Employed by maintenance technicians and engineers to monitor the condition of lubricating greases in machinery and equipment, detecting changes in consistency that may indicate degradation or contamination.

- Grease Selection: Helps users select the appropriate grade or type of lubricating grease based on its penetration characteristics and operating requirements, such as temperature, load, and speed.

- Equipment Lubrication: Guides the proper lubrication of machinery components, such as bearings, gears, and seals, by ensuring the correct consistency of applied grease for optimal performance and durability.

- - Performance Evaluation: Assists in evaluating the effectiveness of lubricating greases in reducing friction, wear, and corrosion in mechanical systems, thereby extending equipment service life and minimizing downtime.

The Cone Penetration Tester for lubricating grease consists of a standardized cone-shaped penetrometer probe attached to a calibrated rod or shaft. The probe is vertically driven into a sample of lubricating grease at a controlled rate, and the depth of penetration is measured and recorded. The penetration depth indicates the consistency or firmness of the grease, with softer greases exhibiting greater penetration depths and harder greases displaying lower penetration depths. The test results provide valuable information on the rheological properties of lubricating greases, including their resistance to deformation, shear stability, and structural integrity. This helps lubricant manufacturers, users, and maintenance professionals ensure the optimal performance and reliability of lubricated machinery and equipment.

|

penetration display |

LCD digital display,precision 0.01mm (0.1 cone penetration) |

|

maximum sounding depth |

greater than 620 cone penetration |

|

timer setting tange |

0~99 seconds±0.1seconds |

|

instrument power supply |

220V±22V,50Hz±1Hz |

|

cone penetration display battery |

LR44H button battery |

-

Differences between open cup flash point tester and closed cup flash point testerFlash point is the lowest temperature at which the test flame causes the sample vapor to ignite and the flame to spread to the surface of the liquid under the specified test conditions. The burning point is the temperature at which the sample is heated up and can burn continuously for at least 5 seconds on the basis of the flash point. The flash point and the burning point are used to indicate whether there are highly volatile or flammable substances in relatively non-volatile or flammable substances. They are one of the important parameters for the transportation, storage, operation and safety management of petroleum products.Detail

Differences between open cup flash point tester and closed cup flash point testerFlash point is the lowest temperature at which the test flame causes the sample vapor to ignite and the flame to spread to the surface of the liquid under the specified test conditions. The burning point is the temperature at which the sample is heated up and can burn continuously for at least 5 seconds on the basis of the flash point. The flash point and the burning point are used to indicate whether there are highly volatile or flammable substances in relatively non-volatile or flammable substances. They are one of the important parameters for the transportation, storage, operation and safety management of petroleum products.Detail -

The Reliable Load Tap ChangerWhen it comes to enhancing the efficiency and performance of transformers, a load tap changer transformer is essential.Detail

The Reliable Load Tap ChangerWhen it comes to enhancing the efficiency and performance of transformers, a load tap changer transformer is essential.Detail -

The Essential Guide to Hipot TestersWhen it comes to ensuring electrical safety and compliance, a reliable hipot tester is indispensable.Detail

The Essential Guide to Hipot TestersWhen it comes to ensuring electrical safety and compliance, a reliable hipot tester is indispensable.Detail